Mold adjusting and locking device of plastic injection molding machine

A technology of injection molding machine and mold clamping device, which is applied in the field of direct pressure gear linkage mold adjustment and mold clamping device, can solve the problems of lack of amplification function, reduced work efficiency, extended cycle period, etc., so as to shorten the molding cycle period and improve the Productivity and the effect of improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

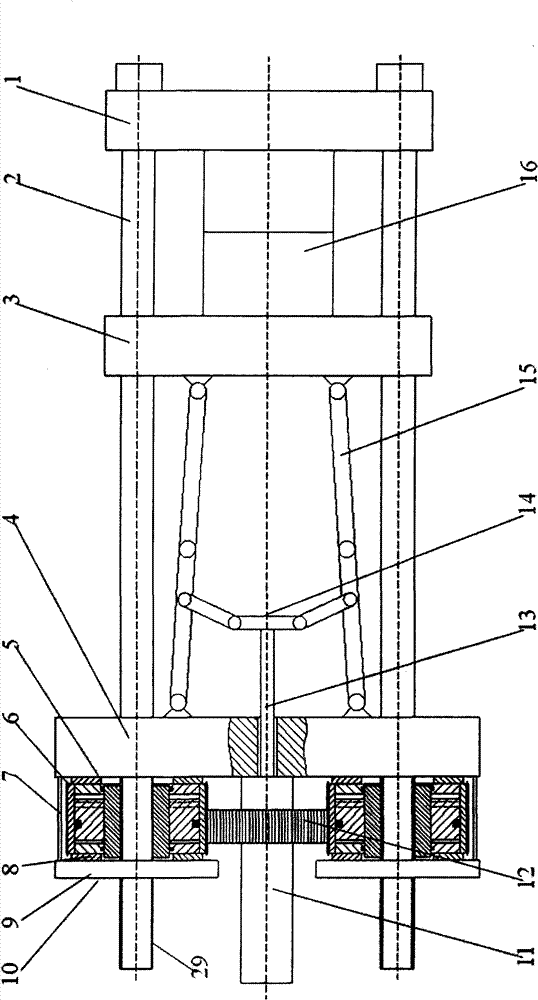

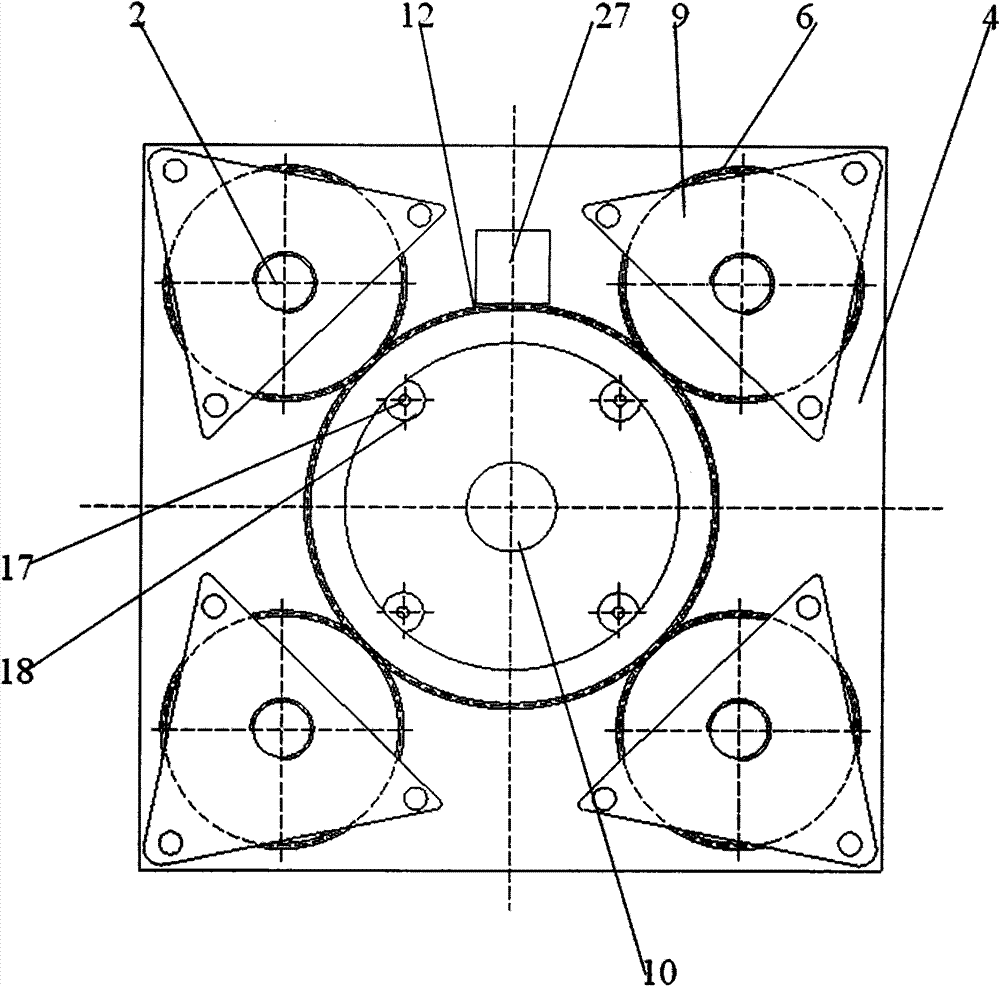

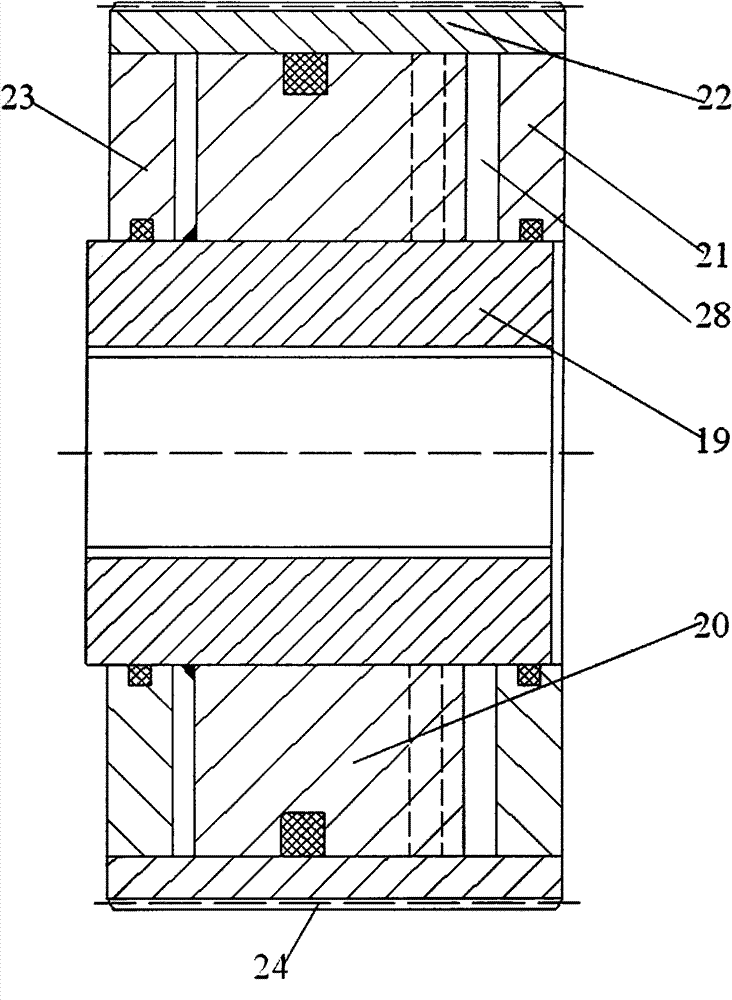

[0017] Such as figure 1 and figure 2 As shown, a mold adjusting and locking device for a plastic injection molding machine is mainly composed of a fixed template 1, a moving template 3, a rear template 4, a tie rod 2, a toggle mechanism 15, a mold clamping cylinder 11 and a mold adjusting and locking device 10, Four pull rods 2 pass through the fixed template 1, the movable template 3 and the rear template 4 in turn, the fixed template 1 is fixed, one end of the pull rod 2 is fixedly connected with the fixed template 1, and the rear template 4 is arranged on the threaded section 29 of the pull rod 1; The mechanism 15 is arranged between the movable template 3 and the rear template 4, the clamping cylinder 11 is arranged on the rear template 4, the piston rod 13 of the clamping cylinder passes through the rear template 4 and is connected with the crosshead 14 of the toggle mechanism; the mold adjustment and clamping device 10 It is composed of mold clamping oil cylinder 6, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com