Fixture for machining annular parts and method for machining parts through fixture

A ring-shaped part and fixture technology, used in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of inconvenient clamping and elastic deformation due to poor radial rigidity, and achieve the effect of avoiding processing errors and improving processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

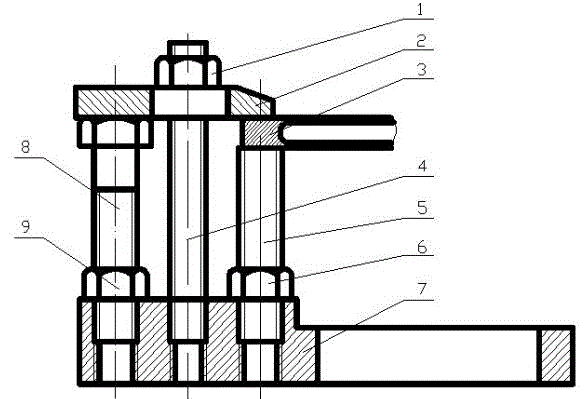

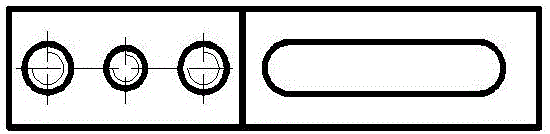

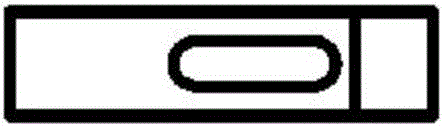

[0025] figure 1 , 2 Shown in and 3, the specific implementation is as follows:

[0026] A fixture for processing ring parts, including a support base 7 with a boss on the top, three support columns are installed on the boss, the three support columns are respectively support column I4, support column II8 and support column III5, support column I4, The length of the supporting column II8 and the supporting column III5 protruding from the boss decreases successively. A pressing plate 2 is installed on the top of the supporting column II8, and the pressing plate 2 is pressed on the top of the supporting column II8 through the pressing block 1 installed on the supporting column I4. And the bottom of one end of the pressing plate 2 cooperates with the top of the support column III5 to clamp the workpiece 3 to be processed.

[0027] The boss is provided with three installation holes I that run through the support base 7, the support column I4, the support column II8 and the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com