Rear energy storage type super-high speed plasticizing injection device

An injection device and ultra-high-speed technology, applied in the field of plasticizing injection devices, can solve the problems of low control precision, difficult acceleration, high energy consumption, etc., and achieve the effect of solving difficult control, high energy consumption, and simple connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

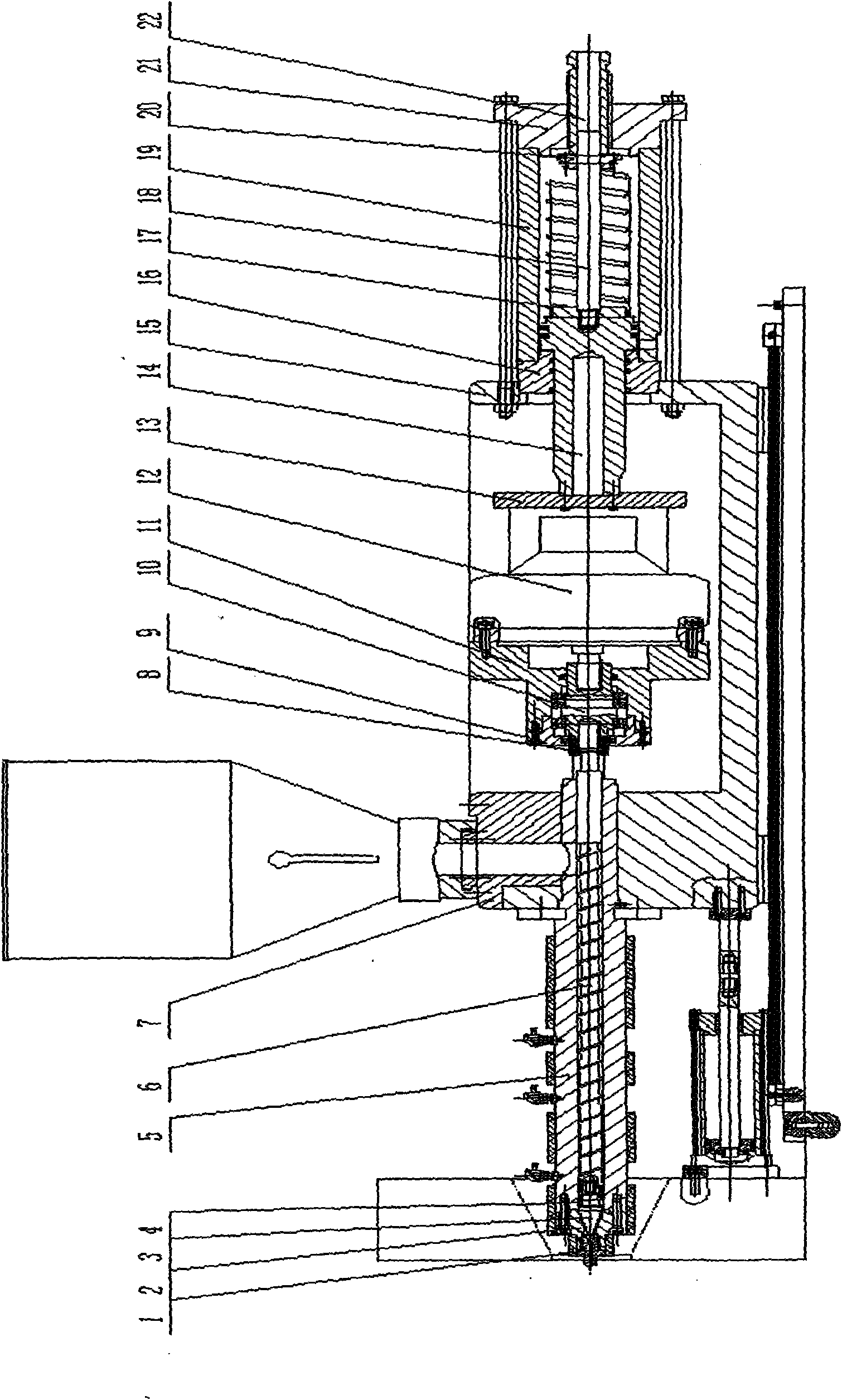

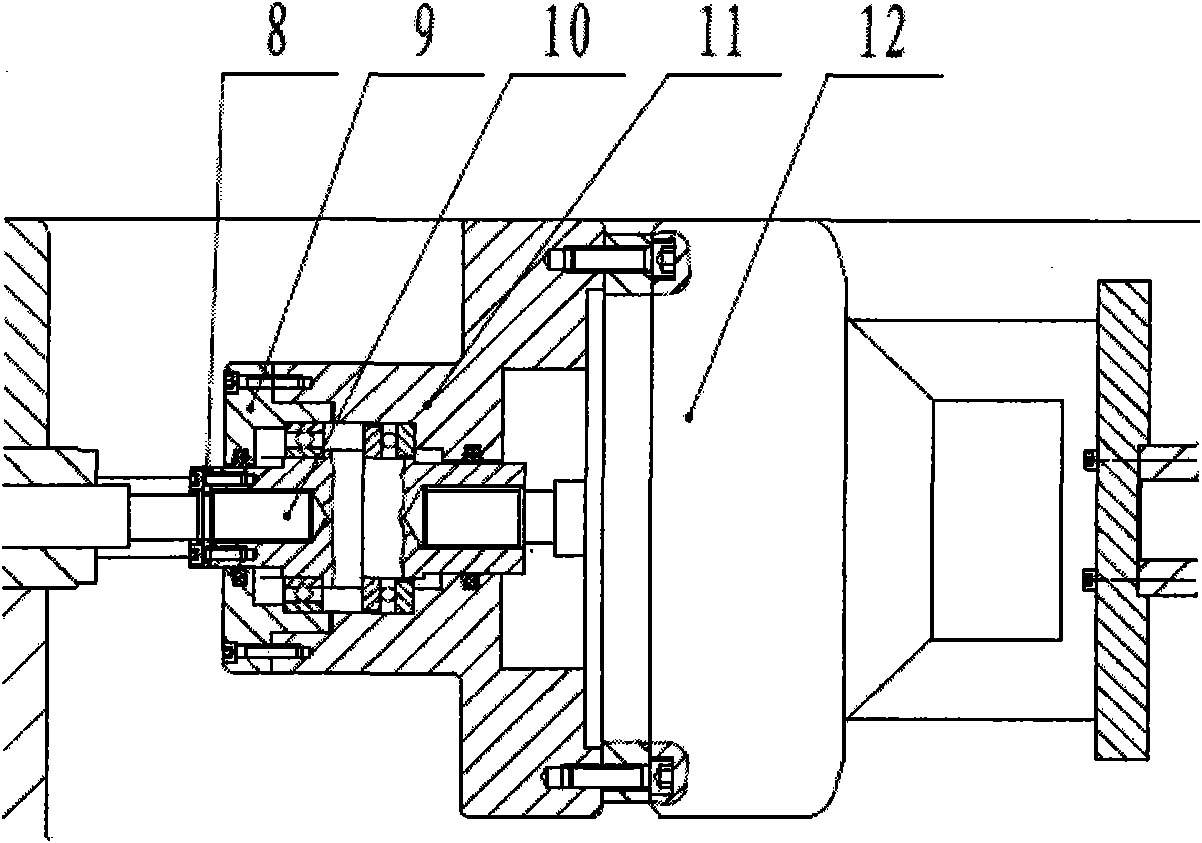

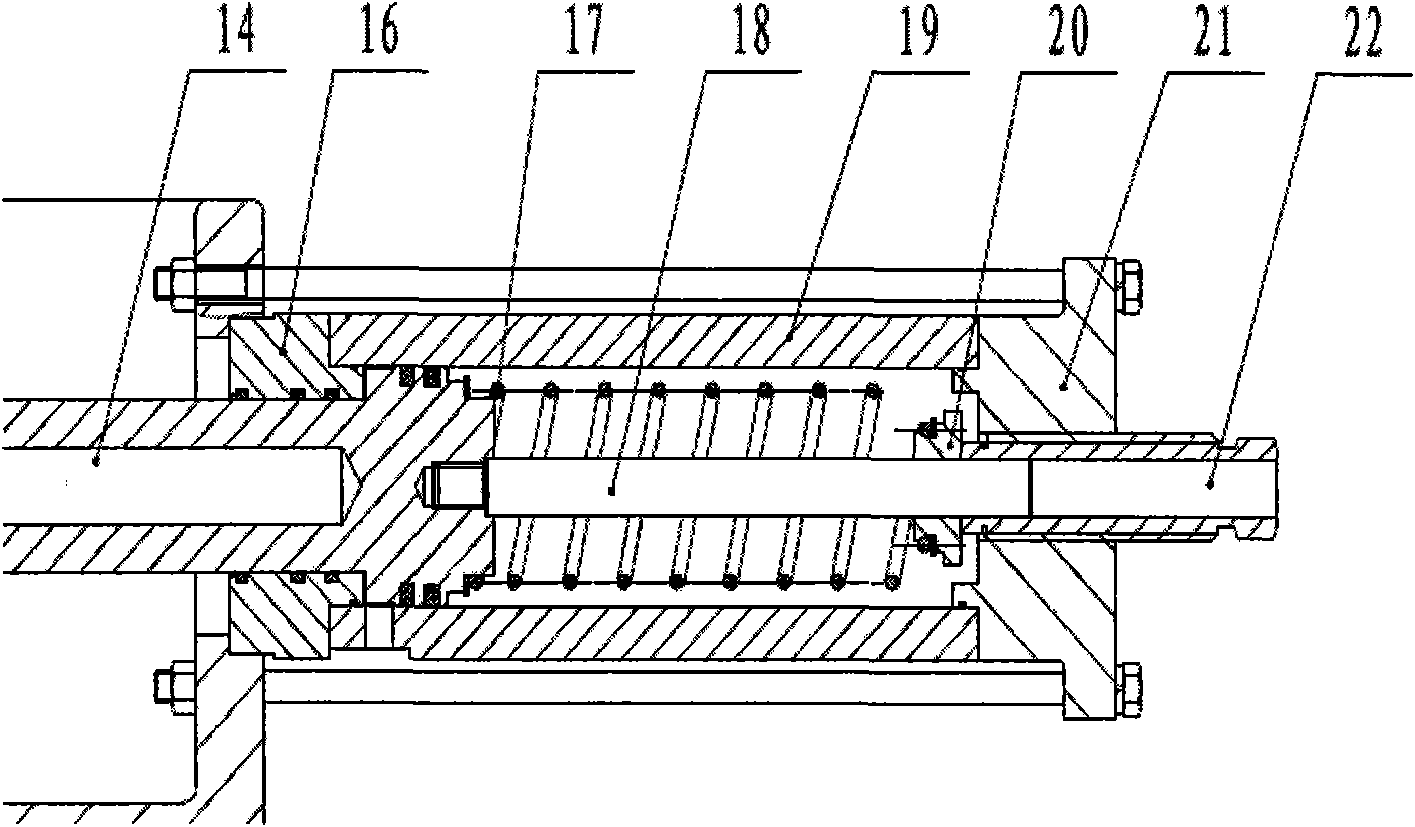

[0021] Such as figure 1 As shown, the energy storage type ultra-high-speed plasticizing injection device is mainly composed of: nozzle 1, barrel 5, screw 6, hydraulic motor 12, injection piston 14, injection seat 15, injection cylinder front cover 16, injection cylinder body 19, Injection cylinder back cover 21, spring 17, adjustment sleeve 22 are formed. Wherein, the barrel 5, the injection seat 15, the hydraulic motor 12, the injection piston 14, the spring and the adjustment sleeve 22 are sequentially aligned and connected with each other. The injection seat 15 can slide relatively, the feeding sleeve 7 is placed on the injection seat 15 , the tail of the screw rod 6 is connected with the spline shaft 10 through the spline, and the hydraulic motor 12 is connected with the screw rod 6 through the spline shaft 10 . The injection cylinder is placed on the injection seat 15 rear, and the spring 17 is contained in the injection cylinder, and the spring 17 can be freely compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com