High-precision large-stroke triaxial fast cutter servo device

A technology of servo device and large stroke, applied in the field of tool servo device, can solve the problems of small stroke and difficult to meet the requirements of free-form surface processing, and achieve the effect of inhibiting lateral movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

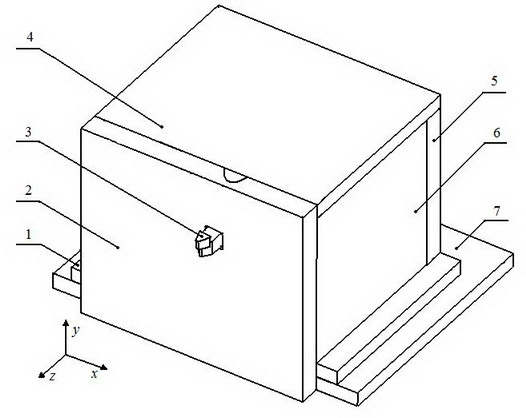

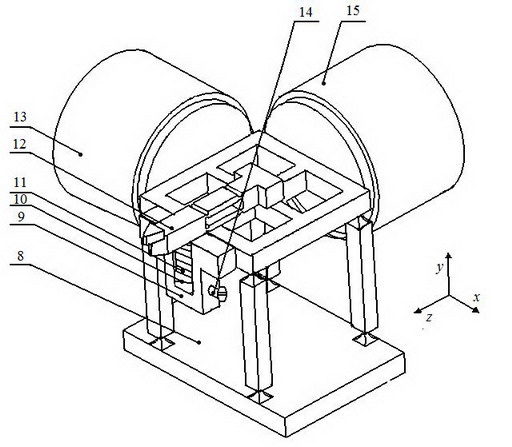

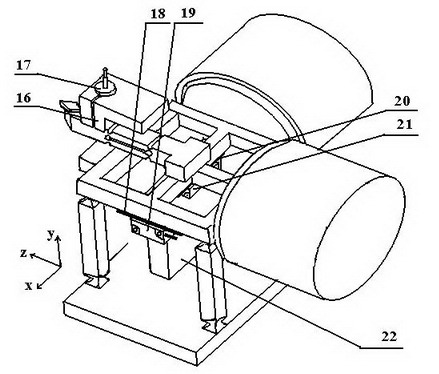

[0017] Right baffle 1, front baffle 2, rear baffle 5, left baffle 6 lower sides are respectively fixedly connected with base 7, the top is fixedly connected with upper cover 4 respectively, the bottom of hinge bracket 8 is fixed on base 7, and the upper part is for moving part, the middle is four connecting rods with hinges, the stator of the X-direction voice coil motor 13 is fixed on the right baffle 1, the mover is fixed on the upper right side of the hinge bracket 8, and the stator of the Z-direction voice coil motor 15 is fixed On the rear baffle 5, the mover is fixed on the rear upper part of the hinge bracket 8; the piezoelectric stack seat 9 is fixed on the middle position of the front upper part of the hinge bracket 8, and the piezoelectric stack actuator 11 is in the middle groove. The wedge block 10 is adjusted by the pre-tightening screw 14 to realize the pre-tightening of the piezoelectric stack. The movable end of the piezoelectric stack actuator 11 is in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com