Electric fluid flow heater with heating element support member

A technology for electric heaters and fluid heating, which is applied in the direction of fluid heaters, heating element shapes, water heaters, etc., and can solve problems such as damage to heating elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

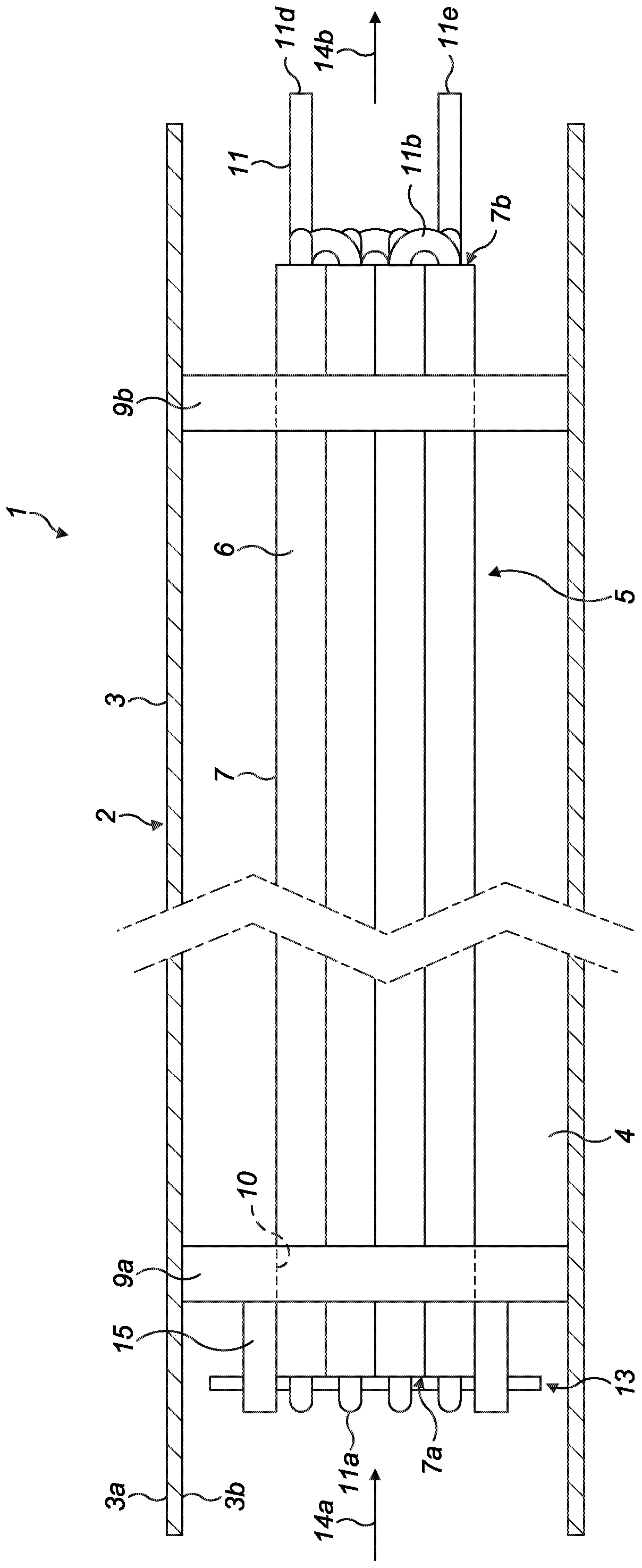

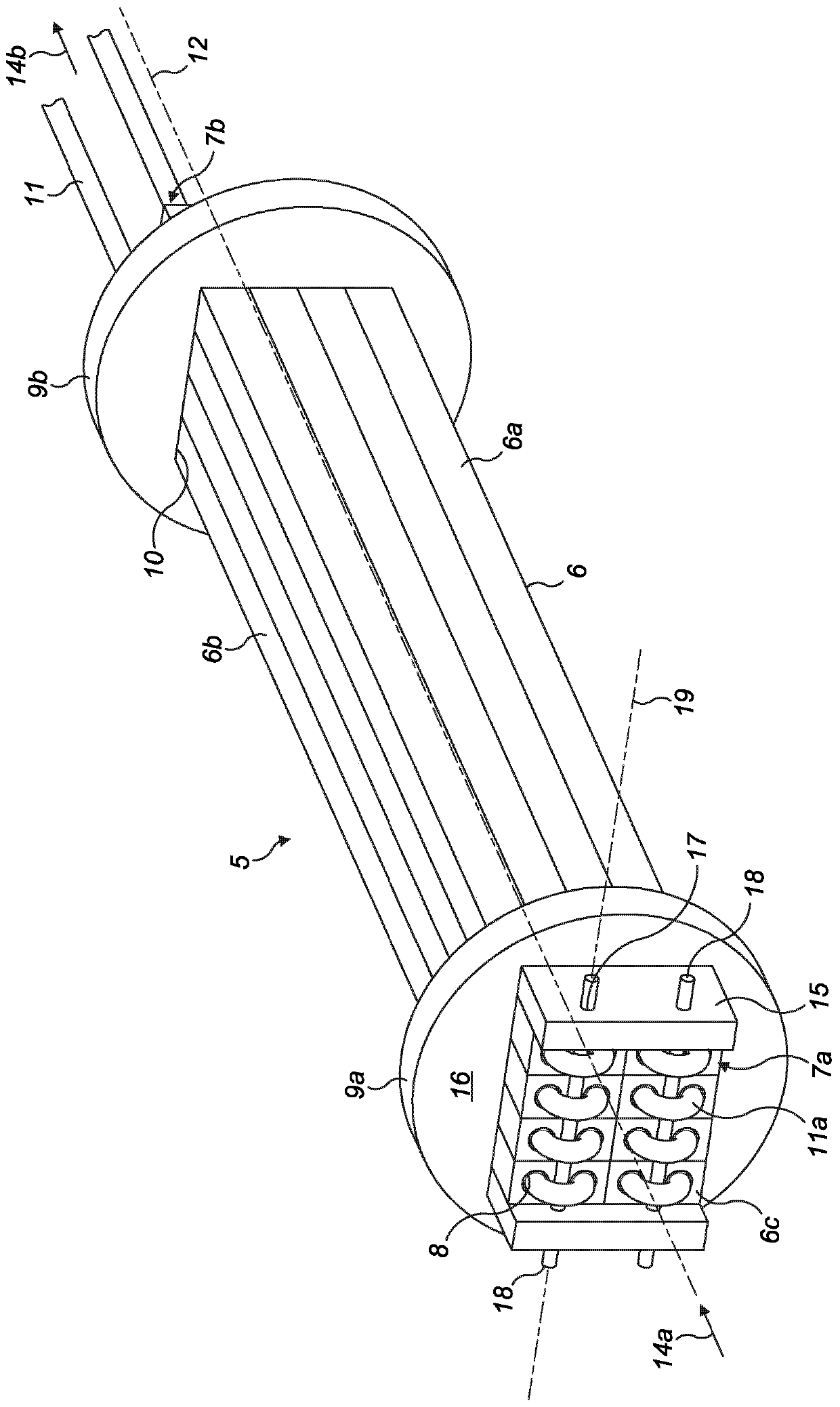

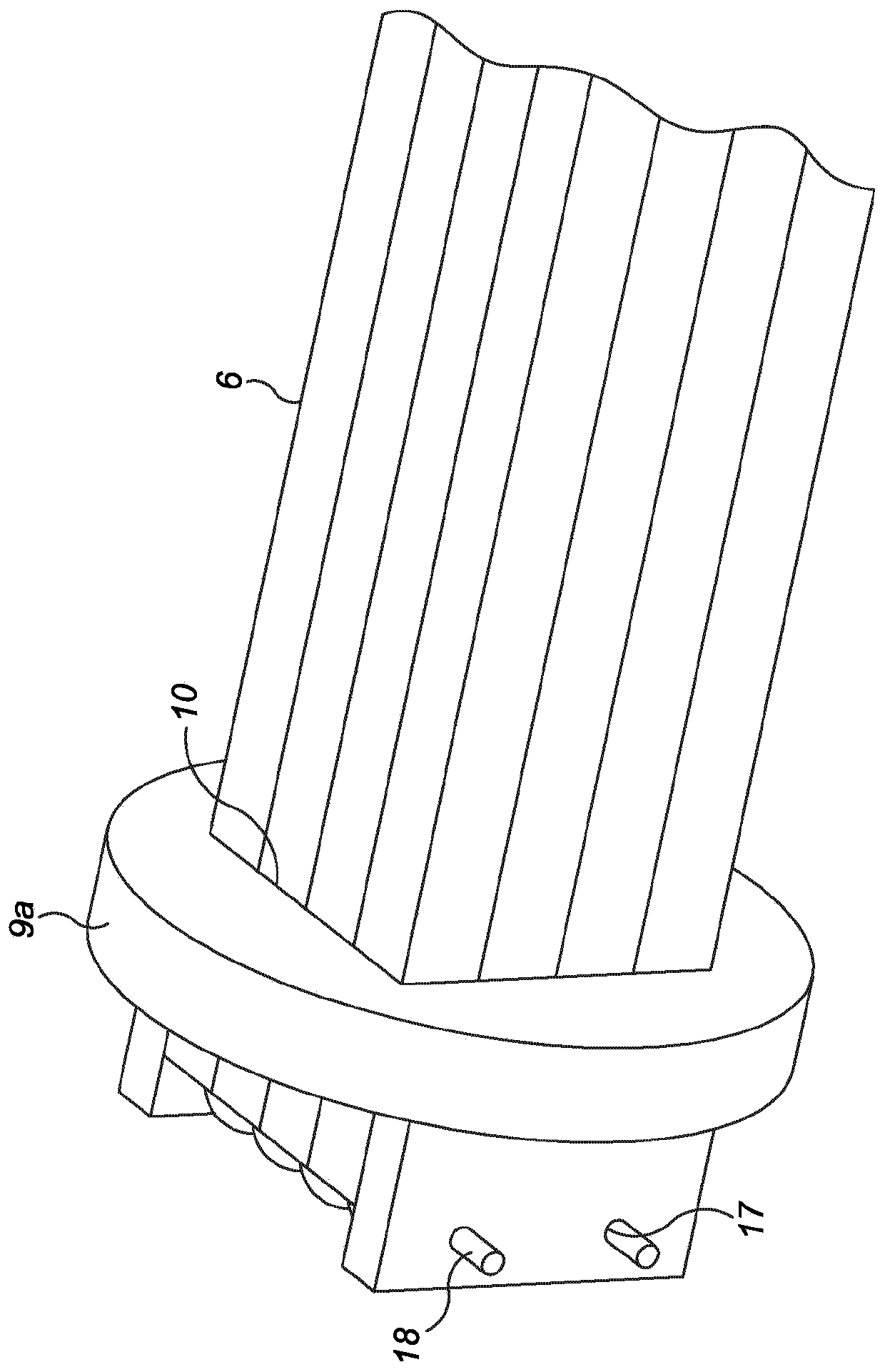

[0046] refer to figure 1 , figure 2 and image 3 , the electric heater 1 comprises a housing 2 in the form of a cylindrical sheath 3 (having an inwardly facing surface 3b and an outwardly facing surface 3a, respectively), which defines a housing which is open at both axial ends. Internal chamber 4. A heating assembly generally indicated by reference numeral 5 is mounted within the chamber 4 . The heating assembly 5 consists of a plurality of longitudinally elongated jacket elements 6 assembled and held together to form a longitudinally elongated jacket block 7 . Each elongated jacket element 6 includes a longitudinally extending longitudinal bore 8 extending the entire length of each jacket element 6 so that between the first axial end 7a and the second axial end 7a of the jacket block 7 The two axial ends are open at the end 7b. The jacket element 6 and the jacket block 7 are formed as hollow bodies in which a solid mass and volume extend continuously between a first axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com