Spindle system of electrolysis and magnetic grinding combined machining machine tool

A composite processing and magnetic grinding technology, applied in the field of spindle system transformation, can solve the problems of affecting the processing effect, unfavorable electrolytic magnetic grinding processing, loss along the process, etc., to achieve loss reduction, convenient structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

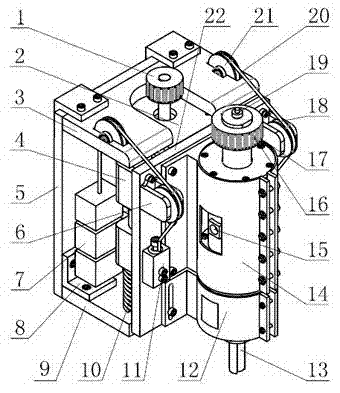

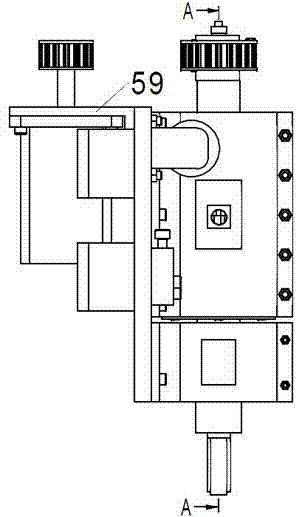

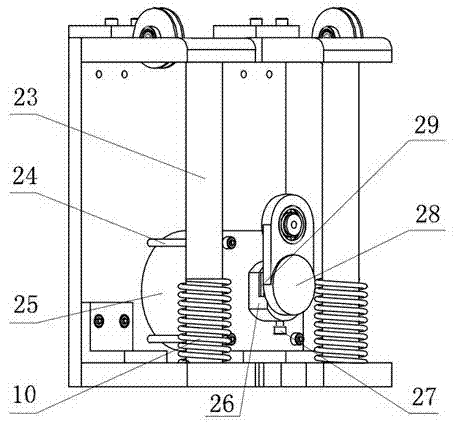

[0031] The structure diagram of the present invention is as figure 1 , 2 , 3, 4, 5, 6, 7 and 8, the present invention includes the following parts: support part, sealing part, power and transmission part, self-priming structure part, electromagnetic circuit system part, power-in and conductive part , high-frequency vibration part, composite processing tool part and embedded copper tube part. The specific implementation of each component is as follows:

[0032] In this embodiment, the supporting part consists of the main shaft fixing plate 22, the main shaft fixing sleeve 14, the upper end cover 32, the upper end ceramic deep groove ball bearing 33, the upper end elastic ring 64, the lower end elastic ring 65, the upper end bearing seat 52, the lower end ceramic deep groove ball bearing Groove ball bearing 39, lower end bearing seat 40, power motor fixing plate 59, lower end cover 47, polished rod vibration seat counterweight wheel 21, main shaft counterweight wheel 18, count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com