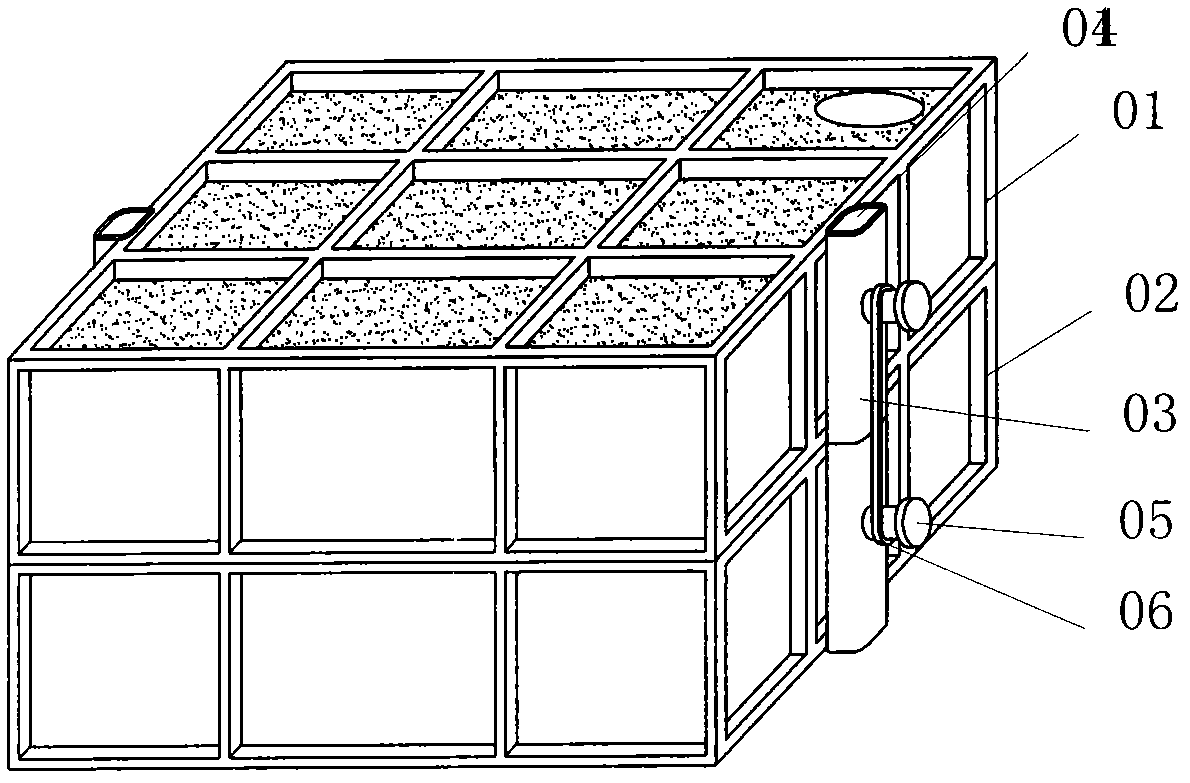

Casting mold for single cylinder diesel body, external casting mold for horizontal parting multi-cylinder diesel body and cast parts, and energy-saving low-carbon casting process of external casting mold

A casting process and horizontal parting technology, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as low positioning accuracy, increased machining allowance, and easy dislocation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

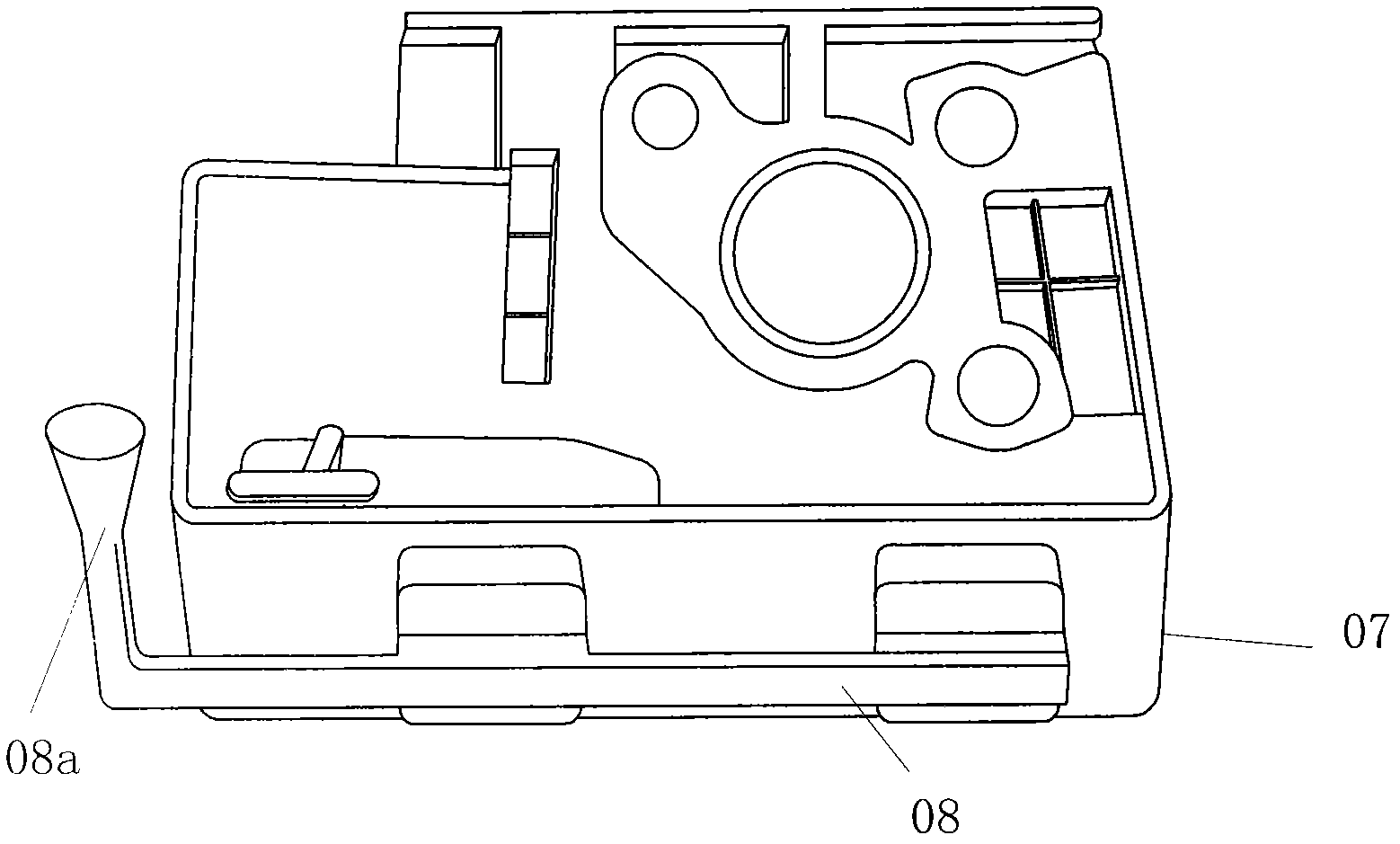

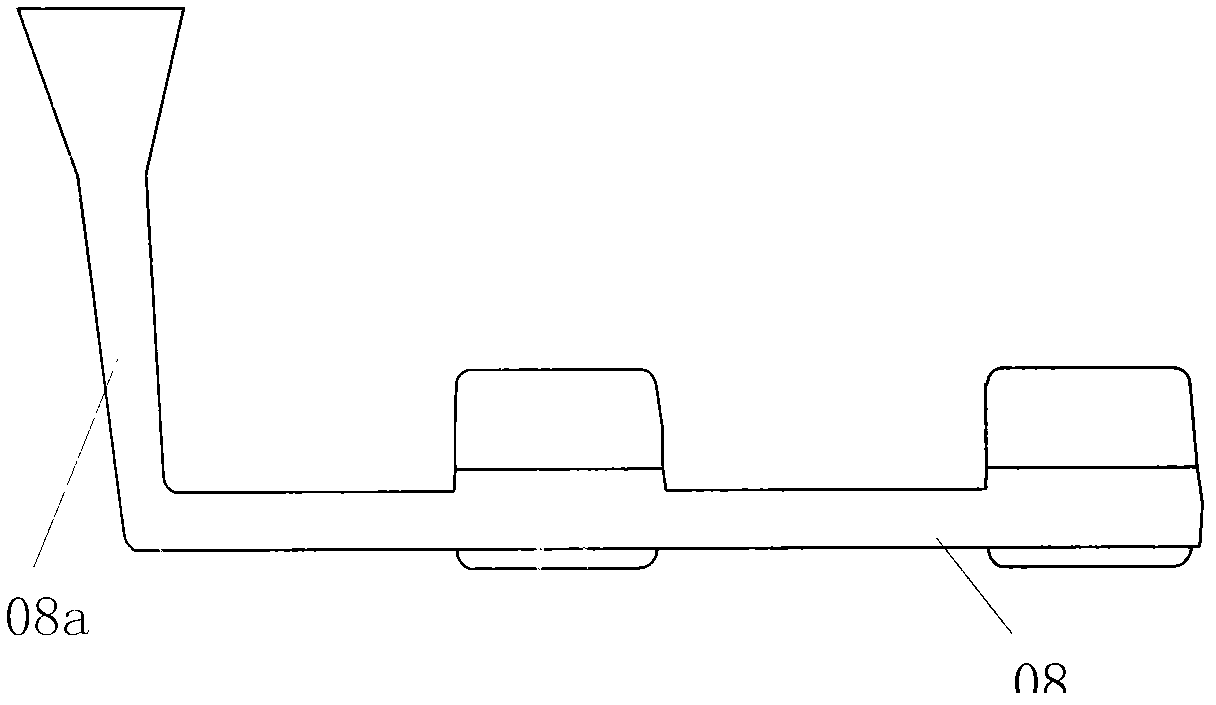

[0115] The energy-saving and low-carbon casting process for a single-cylinder diesel engine body provided by the present invention comprises the following steps:

[0116] A. Making the outer mold: The outer mold includes upper mold and lower mold.

[0117] a. Raw materials for making the outer mold: the same as the raw materials for making the inner mold in the prior art, including sand and resin, in addition, it also includes the curing agent "triethylamine"; in a specific embodiment, take phenolic resin sand as an example, Add phenolic resin to the sand and mix it to make resin sand. When the resin sand is used to form the sand mold in the cold press molding machine, the upper mold and the lower mold of the outer mold sand mold are solidified and formed by spraying the curing agent triethylamine. Generally, the adding ratio of phenolic resin in the sand is 1.0-3.0%, and the amount of spraying triethylamine on an upper mold and a lower mold is 0.10-0.30% of the weight of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com