Deeply pumping process of wall hanging bracket

A deep drawing and crafting technology, applied in the technological field of continuous deep drawing wall hanging bracket, can solve the problems of complicated operation, high mold cost, low labor efficiency, etc., and achieve the effect of reducing the number of projects, long service life and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

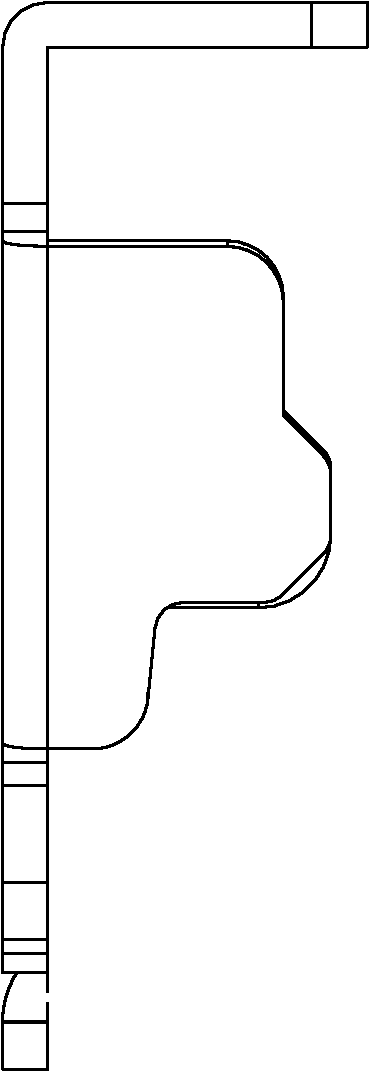

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as image 3 Shown, where A represents the height of the cylinder.

[0024] A deep drawing process for a wall-mounted bracket, characterized in that it comprises the following steps:

[0025] In the first step, the diameter of the deep-drawing punch is 23.8 mm, the R angle is 8.0 degrees, the diameter of the die is 27.0 mm, and the R-angle of the die is 8.0 degrees. The deep-drawing punch is driven by the punching machine to punch the flat plate above the die to obtain Cylindrical with a height of 10.5mm;

[0026] The second step is to move the cylindrical shape stamped in the previous step into the second die. The diameter of the deep drawing punch is 19.1mm, the R angle is 6.0 degrees, the diameter of the second die is 22.3mm, and the R angle of the second die is 7.0 degrees, and the deep-drawing punch is driven by the punch press to punch the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com