Replaceable concrete road bed device of steel trussed bridge and construction method

A technology for steel truss bridges and construction methods, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of difficult maintenance of the bridge deck of the main bridge structure, affecting the safety of the main bridge structure, and large structural dead load, etc., to achieve Reduce the impact of noise, reduce the number of projects, and the effect of passenger comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

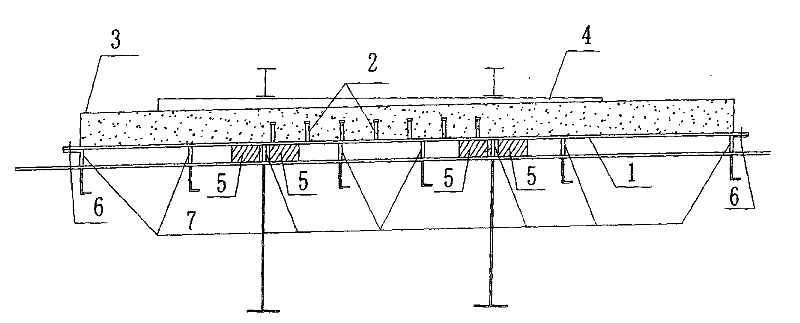

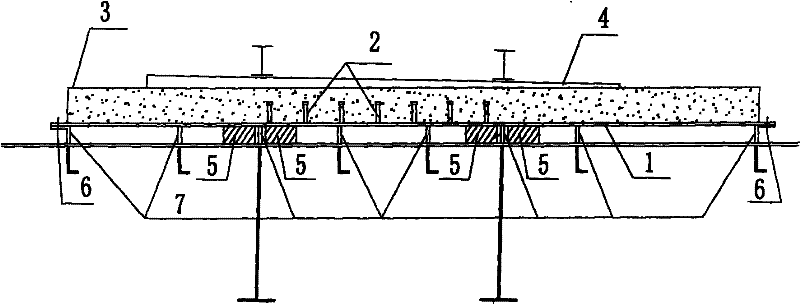

[0009] The replaceable concrete track bed device of the present invention is composed of a concrete track bed slab 3 and a rail bearing platform 4 above it, and a steel bottom plate 1 below. It is fixedly connected with the force transmission member on the bridge surface, and there is a rubber cushion block 5 under the steel base plate, and the rubber cushion block is on the bridge surface.

[0010] Steel floor 1, shear nails 2 and concrete track bed slab 3 are mainly used as load-bearing structures for railway loads, rail platform 4 is used as rail leveling and rail bearing components, and rubber pads 5 are mainly used for shock absorption and noise reduction. The function of part 6 is to connect and fix the replaceable concrete ballast bed with the newly added force transmission member 7 in the main structure. Replacement concrete track bed.

[0011] The specific construction steps of the construction method of the present invention are: when manufacturing the main bridge, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com