Correction device and correction method for inner ring of engine crankcase

An engine case and shape correction technology is applied to the shape correction device of the inner ring of the engine case and the field of shape correction, which can solve the problems of difficult, thin-walled and easily deformed inner ring control, etc. The effect of preventing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

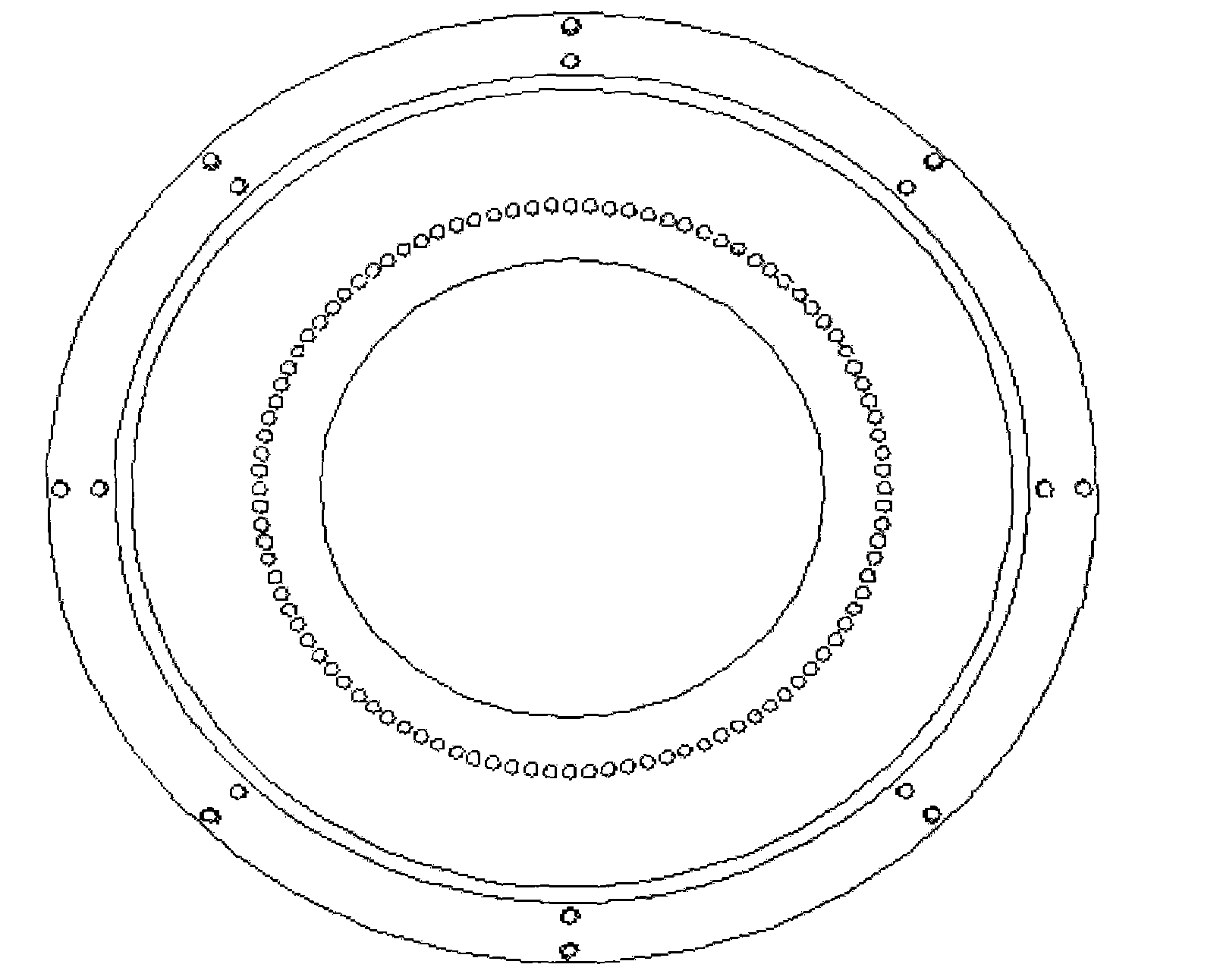

Image

Examples

Embodiment Construction

[0019] Describe the present invention in detail below in conjunction with embodiment:

[0020] In this embodiment, a certain type of supercharged engine casing is taken as an example. The casing assembly processed according to the traditional processing method cannot meet the requirements due to the large ellipticity of the inner ring and the low concentricity between the outer surface of the inner ring and the mouth of the casing. Parts use requirements, establish the center of the circle with the mouth of the casing assembly, check the radius of the inner ring flow point, and find that the radius difference is 2-4mm, which seriously deviates from the design state, and cannot be delivered normally. It is necessary to use the shape correction device and shape correction proposed by the present invention method for calibration.

[0021] The correcting device of the inner ring of the engine casing used in this implementation comprises a correcting fixture base 1, a positioning p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com