Optical proximity correction method

An optical proximity effect and area technology, applied in the field of photolithography, can solve the problems of reducing production efficiency and increasing the running time of the optical proximity effect correction system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions and other beneficial effects of the present invention will be apparent through the detailed description of specific embodiments of the present invention below in conjunction with the accompanying drawings.

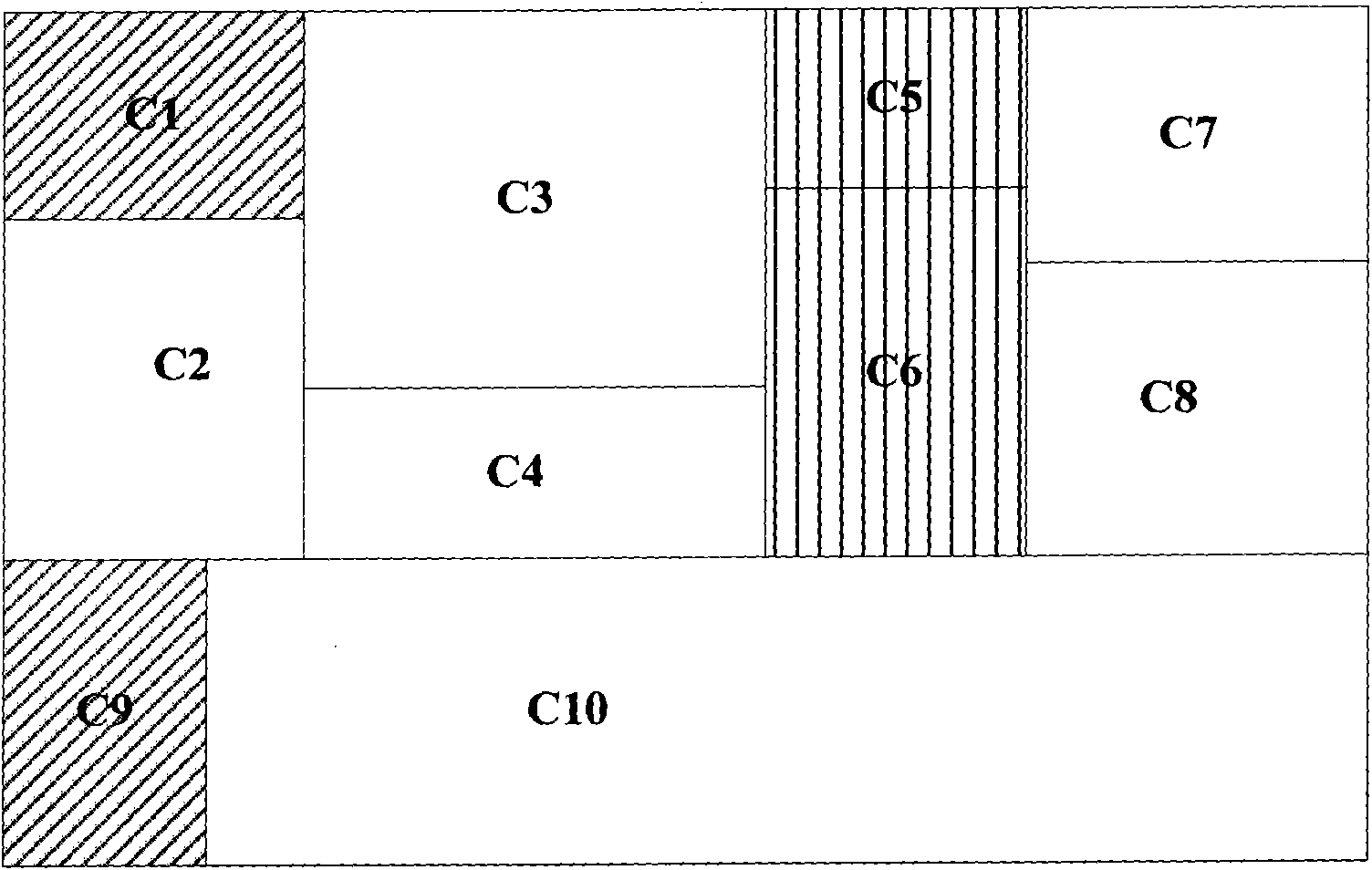

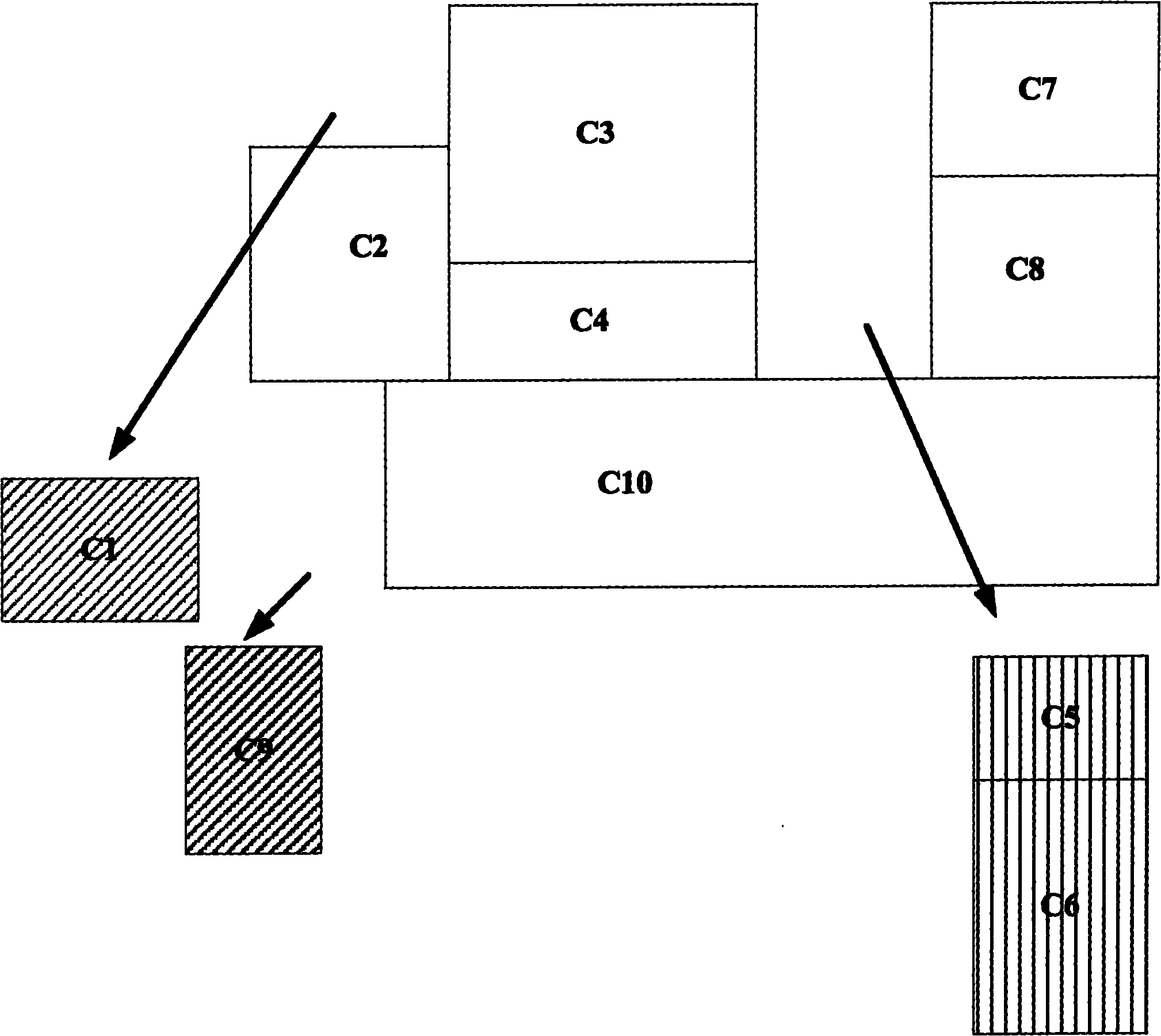

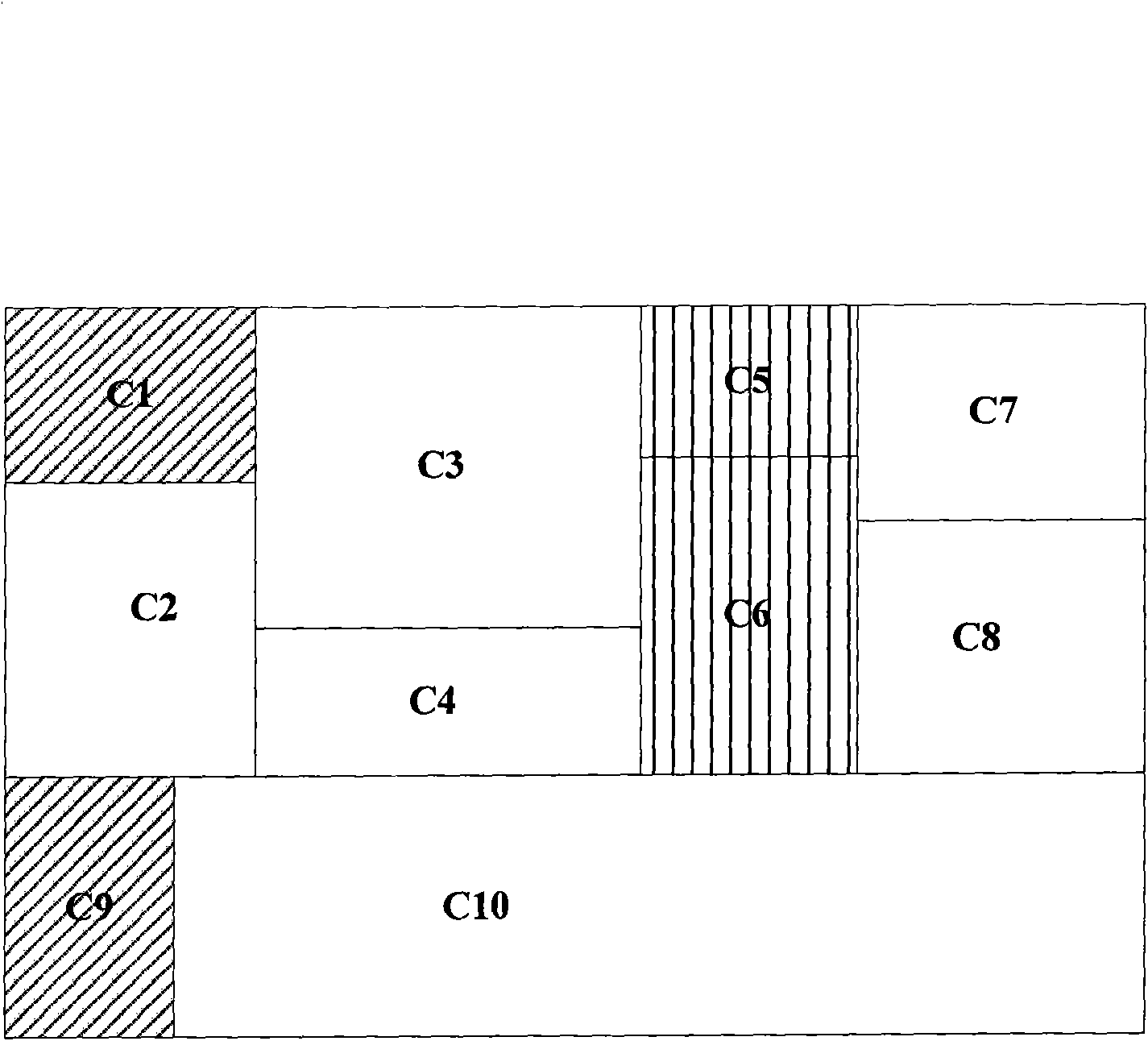

[0014] The optical proximity effect correction method is to divide a layout into multiple regions according to the difference in critical dimension control accuracy. figure 2 is a schematic diagram of the first embodiment of the optical proximity effect correction method. Assume that the vertical bar area (C5, C6) has high requirements for critical dimension control accuracy, the twill area (C1, C9) has medium critical dimension control accuracy requirements, and the blank area (C2, C3, C4, C7, C8, C10) has high requirements for critical dimension control accuracy. The critical dimension control accuracy requirement is low, so the layout is decomposed according to the difference in critical dimension control accuracy. In the preferred decom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com