Pressure vessel having improved sealing arrangement

A technology for pressure vessels and tubular components, which can be applied to pressure vessels, outer walls of vessel structures, manufacturing of vessel structures, etc., and can solve problems such as damage to the sealing performance of O-rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

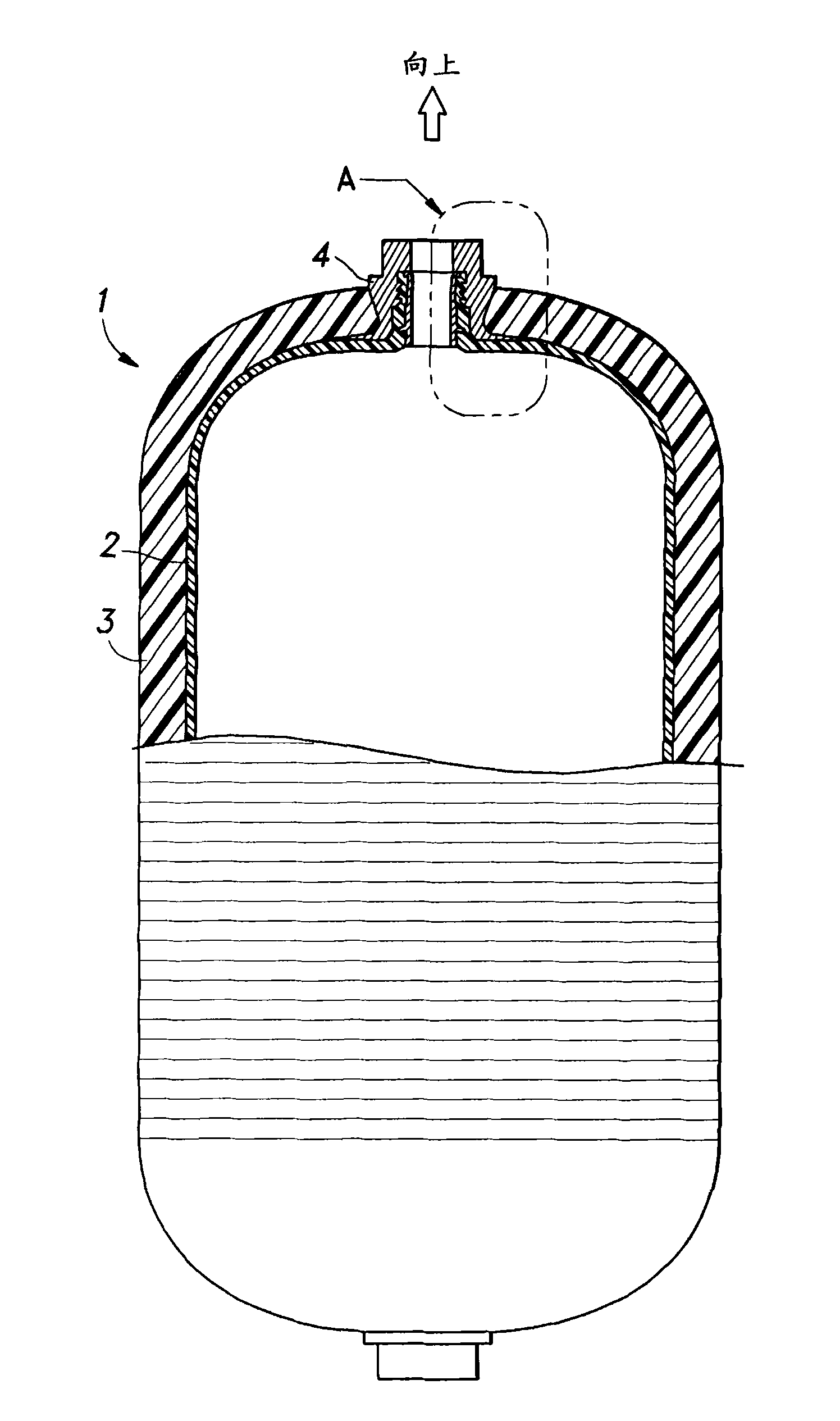

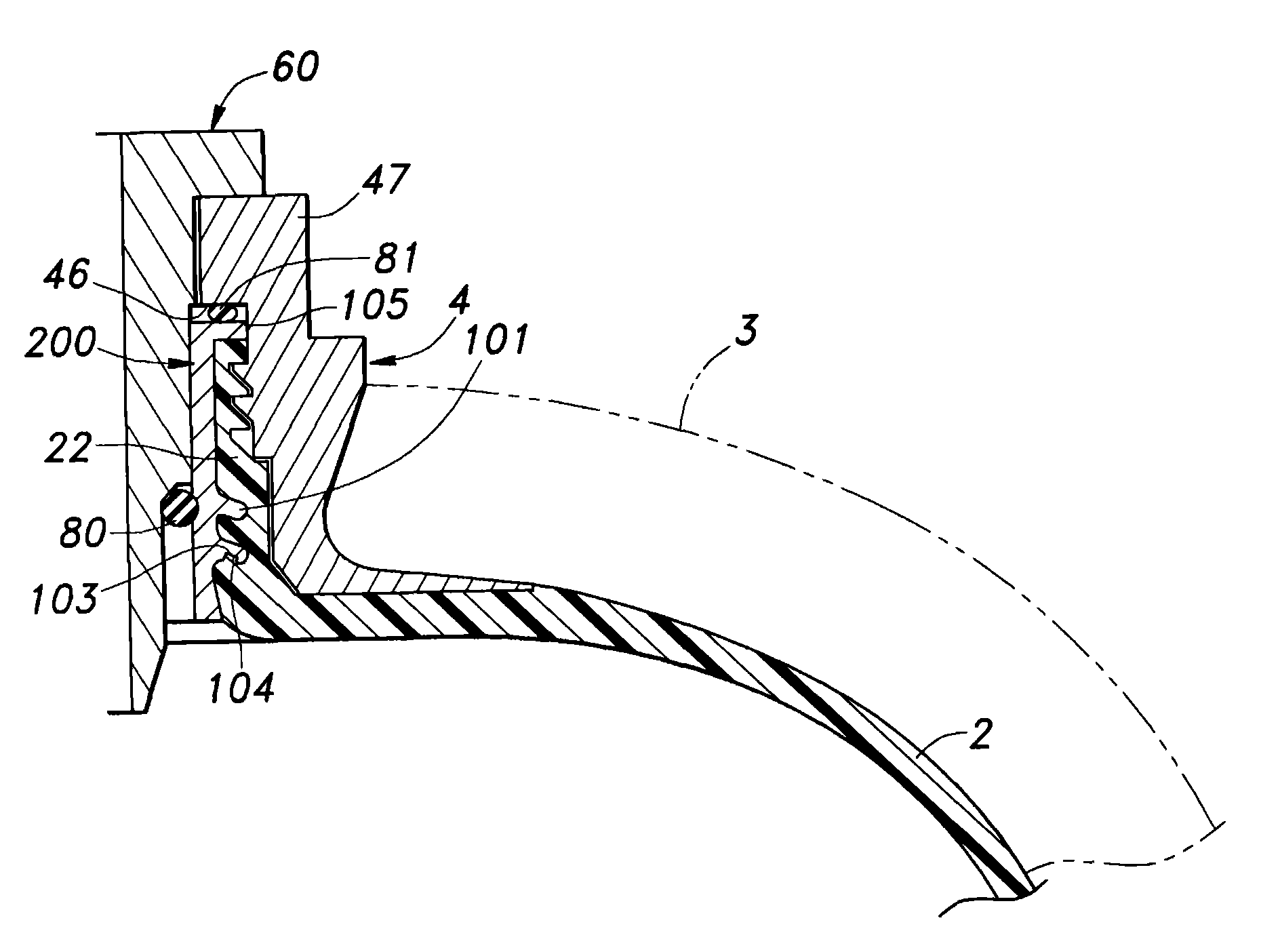

[0020] figure 1 The main parts of a pressure vessel 1 embodying the invention are shown. The pressure vessel 1 includes a resin liner 2 having a cylindrical body portion and a pair of hemispherical axial end portions, a fiber-reinforced resin layer 3 surrounding the outer surface of the resin liner 2 , and fitted to the axial end portions provided on the pressure vessel 1 One of the openings of the mouth4.

[0021] The illustrated pressure vessel 1 can be used in any desired orientation, however, for the purposes of the following description, it is assumed that the pressure vessel 1 is placed in a vertical position with the mouth 4 on top, as shown in the figures.

[0022] The resin liner 2 is made of a material suitable for contacting the gas or liquid to be contained in the pressure vessel 1, which can be selected from various plastic materials such as polyethylene (PE), high-density polyethylene (HDPE), polyamide , polyketone, and polyphenylene sulfide (PPS), depending o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com