Preparation method of composite metal organic framework material colloidal solution and application thereof in optical coatings

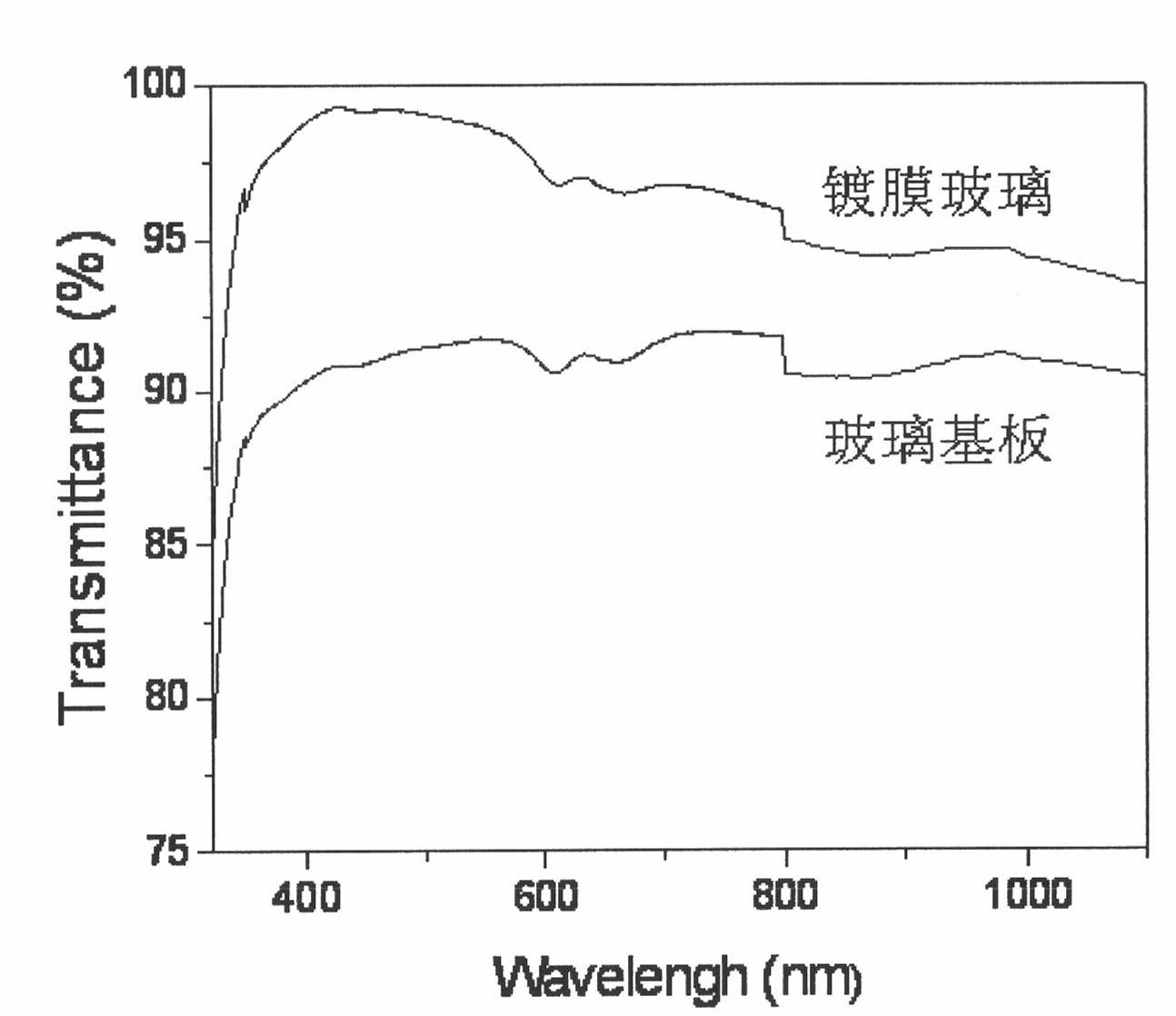

A metal-organic framework, colloidal solution technology, used in coatings, optics, optical components, etc., can solve problems such as application limitations, low refractive index parameters, etc., to achieve good wear resistance and weather resistance, and improve the effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

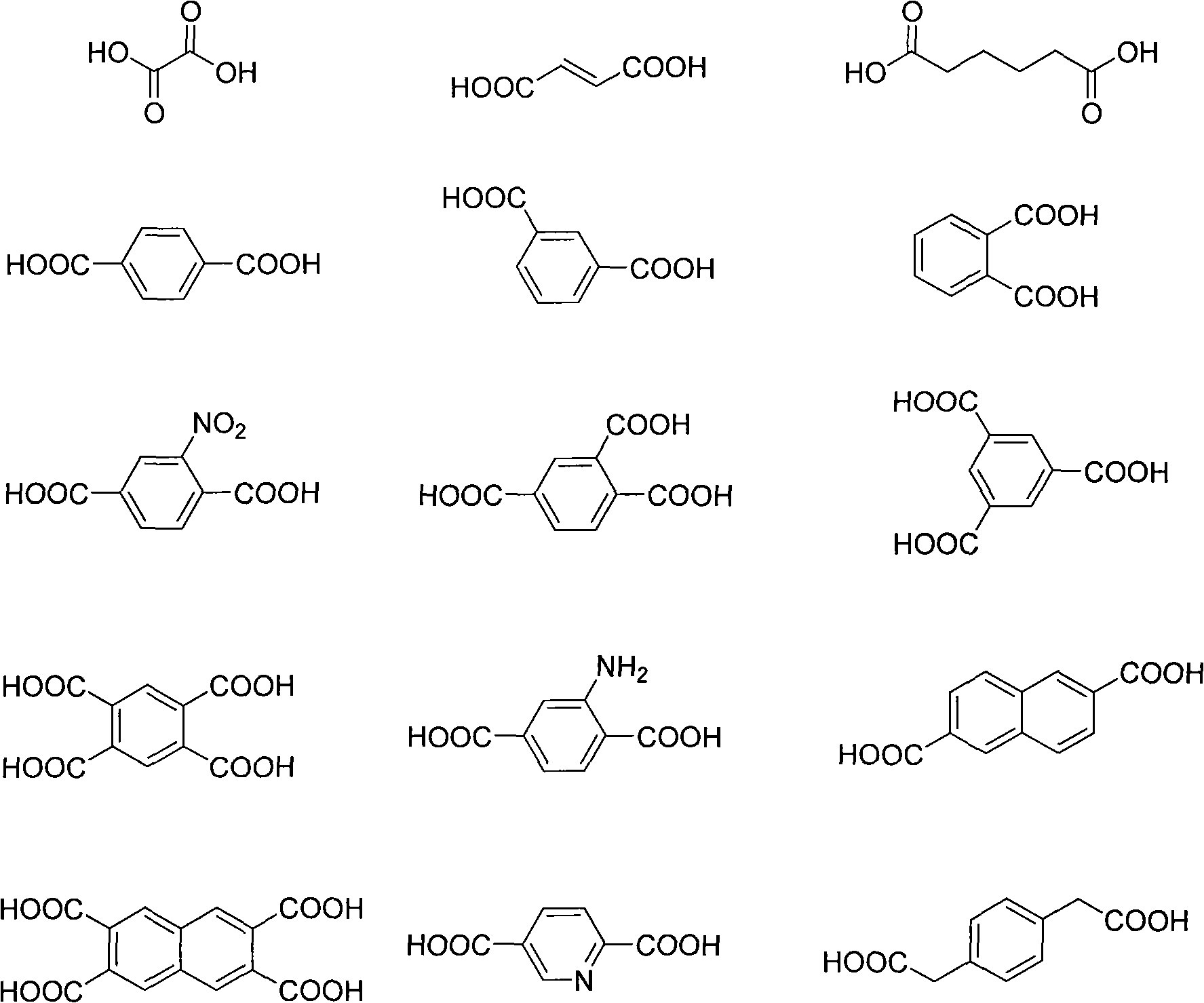

[0034] Tetraethoxysilane and water are mixed at a molar ratio of 1 to 3, add enough ethanol to obtain a homogeneous solution, and add 1 equivalent of acetic acid catalyst (relative to tetraethoxysilane), stir well at room temperature reaction to obtain silica sol.

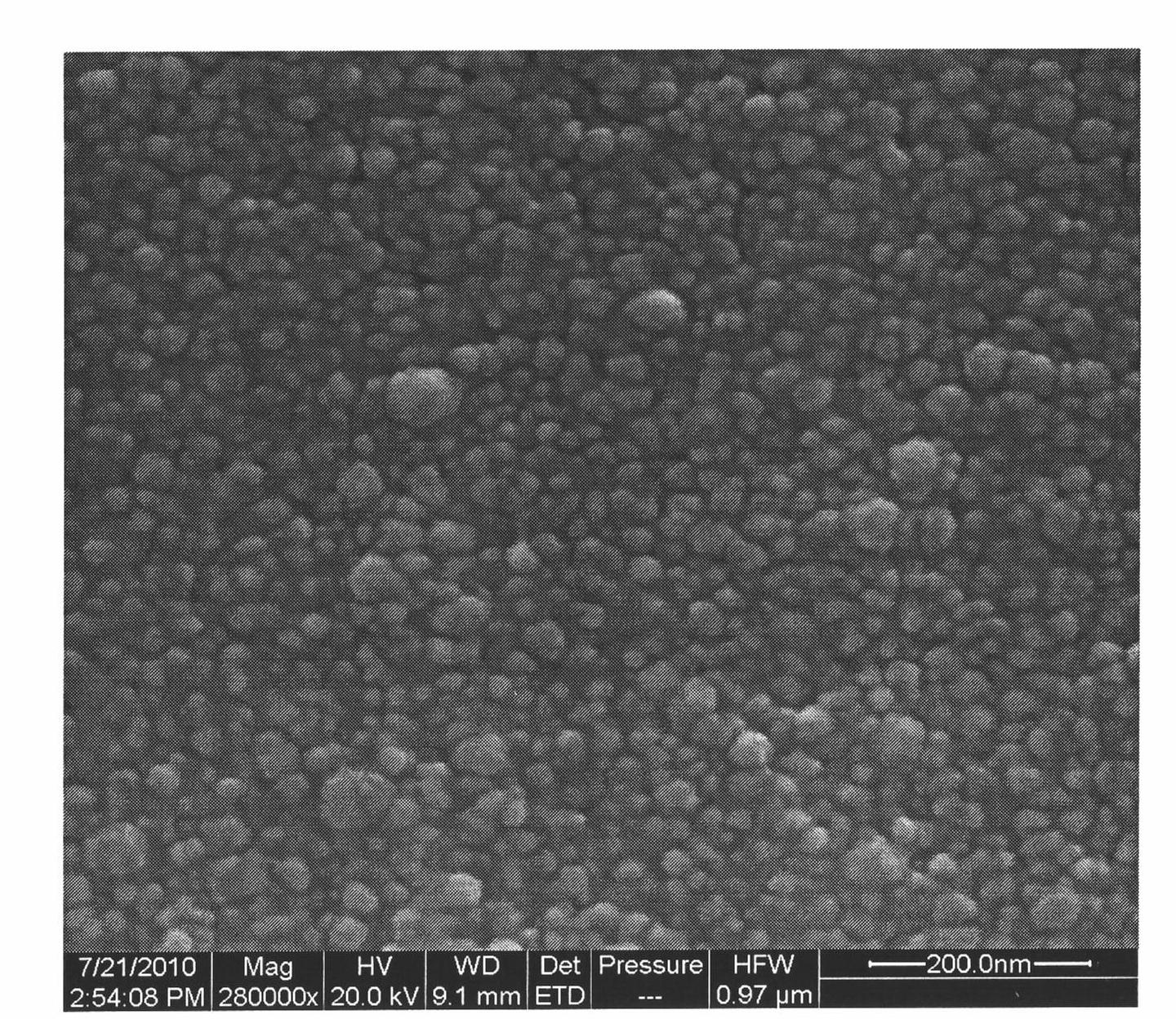

[0035] 2.933g Zn(NO 3 ) 2 ·6H 2O is dissolved in 200 milliliters of methanol, and is completely dissolved under magnetic stirring, and 6.49 grams of 2-methylimidazole is dissolved in 200 milliliters of methanol, and is completely dissolved under magnetic stirring, and then the methanol solution of 2-methylimidazole is quickly poured into Zn ( NO 3 ) 2 ·6H 2 In the methanol solution of O, the reaction was magnetically stirred at room temperature, and the reaction solution became turbid. After 1 hour, the obtained product was separated by a centrifuge, and the obtained solid was dispersed in methanol to obtain 80 grams of Zn(Mim) 2 colloidal solution.

[0036] The above silica sol and Zn(Mim) 2 The colloid so...

Embodiment 2

[0039] Silica sol synthetic method is identical with embodiment 1, Zn(Mim) 2 Colloidal solution synthetic method is identical with embodiment 1, but Zn(Mim) 2 Without separation, directly mix the obtained reaction solution with silica sol, the silica sol accounts for 10-95% by mass, dilute with ethanol, stir and mix evenly at room temperature, and set aside.

[0040] Wash the glass substrate with pure water, dry it in an oven, and after cooling, pass the colloidal solution through the pulling method to coat the glass substrate. After pulling once, the glass is first dried at room temperature, and then placed in a high-temperature furnace The film layer is cured at a temperature of 450°C to 650°C, preferably 500°C to 550°C.

Embodiment 3

[0042] Silica sol and Zn(Mim) 2 Colloidal solution synthetic method is identical with embodiment 1, and silica sol and Zn(Mim) 2 The colloid solution is mixed, the mass percentage of the silica sol is 10-95%, and after magnetic stirring is uniform, 0.01-1% mass percentage of titanium dioxide nanoparticles is added, diluted with ethanol, magnetic stirring is uniform, and the preparation is ready for use.

[0043] Wash the glass substrate with pure water, dry it in an oven, and after cooling, use the above solution to coat the glass substrate by pulling method. After pulling once, dry the glass at room temperature first, and then put it in a high-temperature furnace. The film layer is cured at a temperature of 200°C to 650°C, preferably 400°C to 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com