Production process and equipment for preparing hydrogen by hydrolyzing NaBH4 of fuel cell

A fuel cell, hydrolysis hydrogen production technology, applied in the production of hydrogen, etc., can solve the problems of high manufacturing conditions, alkaline stimulation, high cost, etc., and achieve the effect of ensuring safety and reliability, fast response speed and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

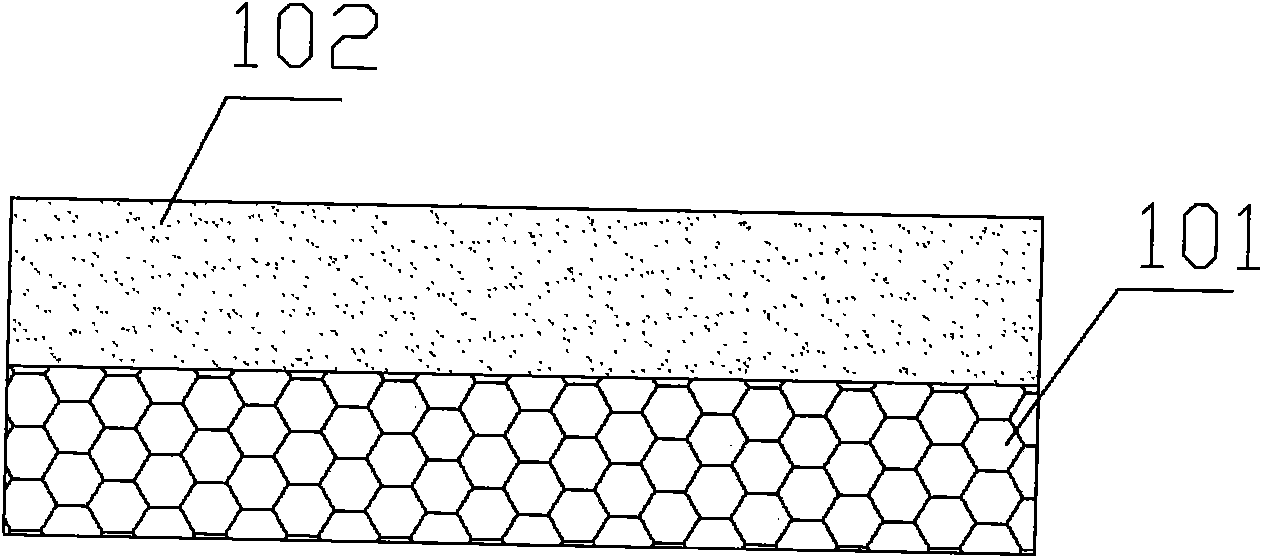

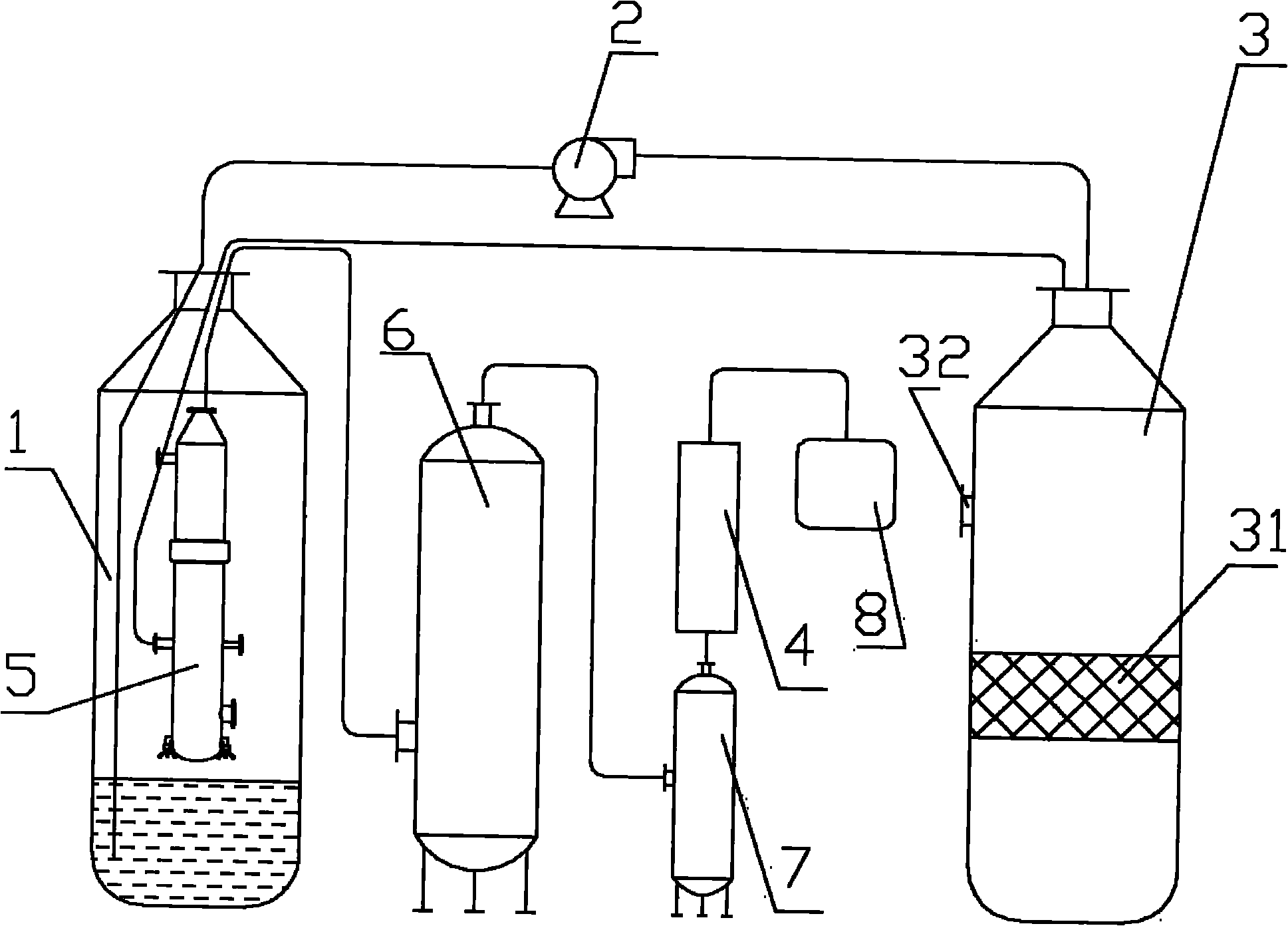

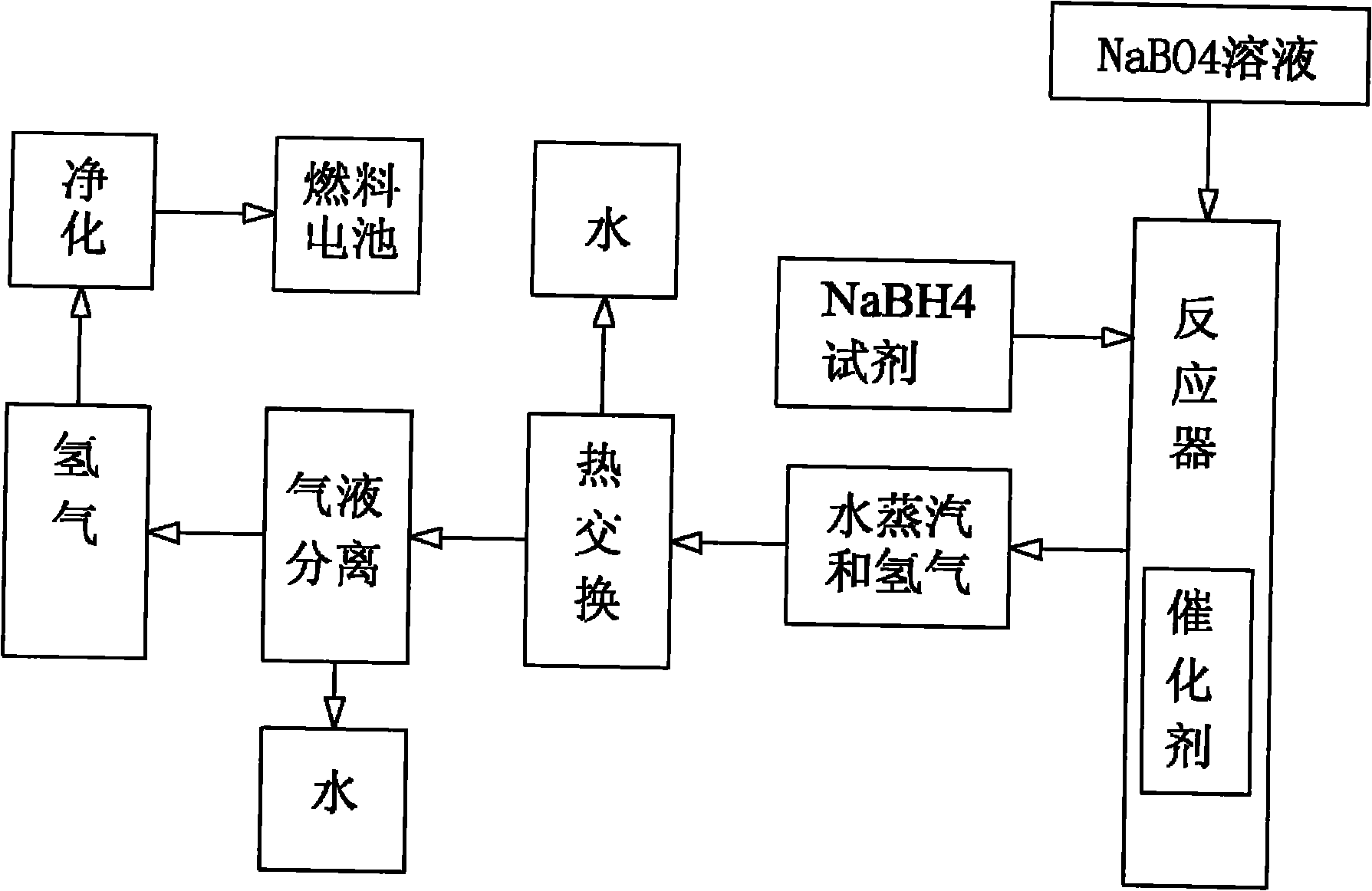

[0028] Example: see Figures 1 to 3 As shown, the NaBH of the fuel cell 4 Hydrolysis hydrogen production process, a, adding catalyst: a catalyst is placed in the reaction tank, and the catalyst is a mixture 102 of Co-B powder and pulp foam bonded and fixed on the foamed nickel sheet 101, wherein, by weight, Co-B Powder: pulp foam = 2: 0.5 ~ 1.5;

[0029] b. Add reaction solvent: add NaBO with a concentration of 15 to 30% into the reaction tank 4 Solution, add NaBH in the reaction tank simultaneously Reagent, NaBH Reagent each component by weight is, NaBH 4 : NaOH: distilled water=15%: 2~3%: 75~85%; react under the constant temperature condition of 55~65 ℃, and produce hydrogen and steam in the reaction tank;

[0030] c. Gas-liquid separation: After the mixed gas of hydrogen and water vapor undergoes heat exchange, the water vapor is condensed into water for recycling;

[0031] d. Purification: The hydrogen after gas-liquid separation is further purified to remove impuritie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com