Hydro-pneumatic suspension system and wheeled vehicle with same

A technology of oil-pneumatic suspension and left suspension, which is applied to the interconnection system, vehicle components, suspension, etc., can solve the problems of inability to realize the active lifting and lowering of the axle, cannot meet the road traffic conditions, and there are few road driving modes, so as to improve road adaptability capability, improved maintainability, and leak-free results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

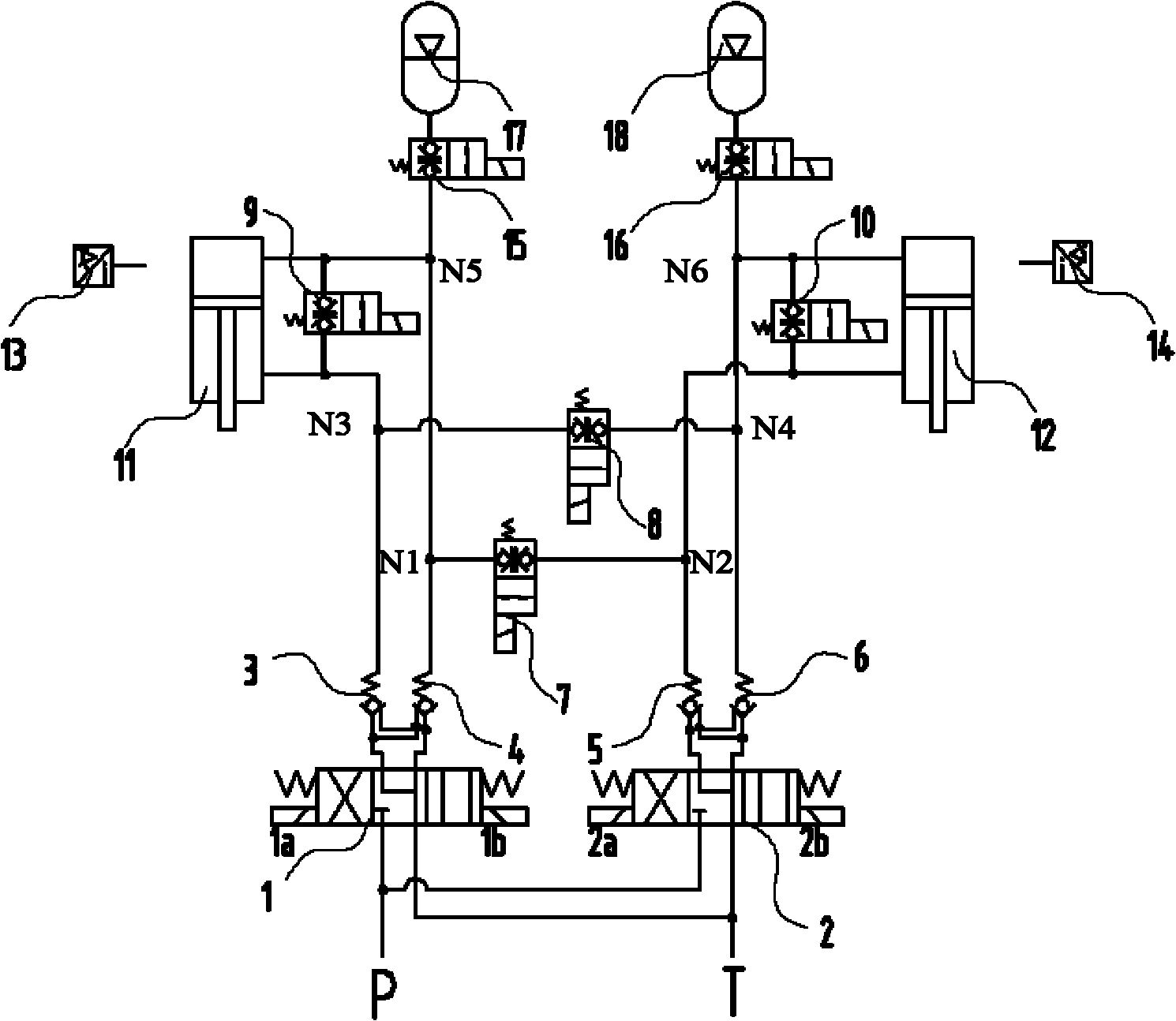

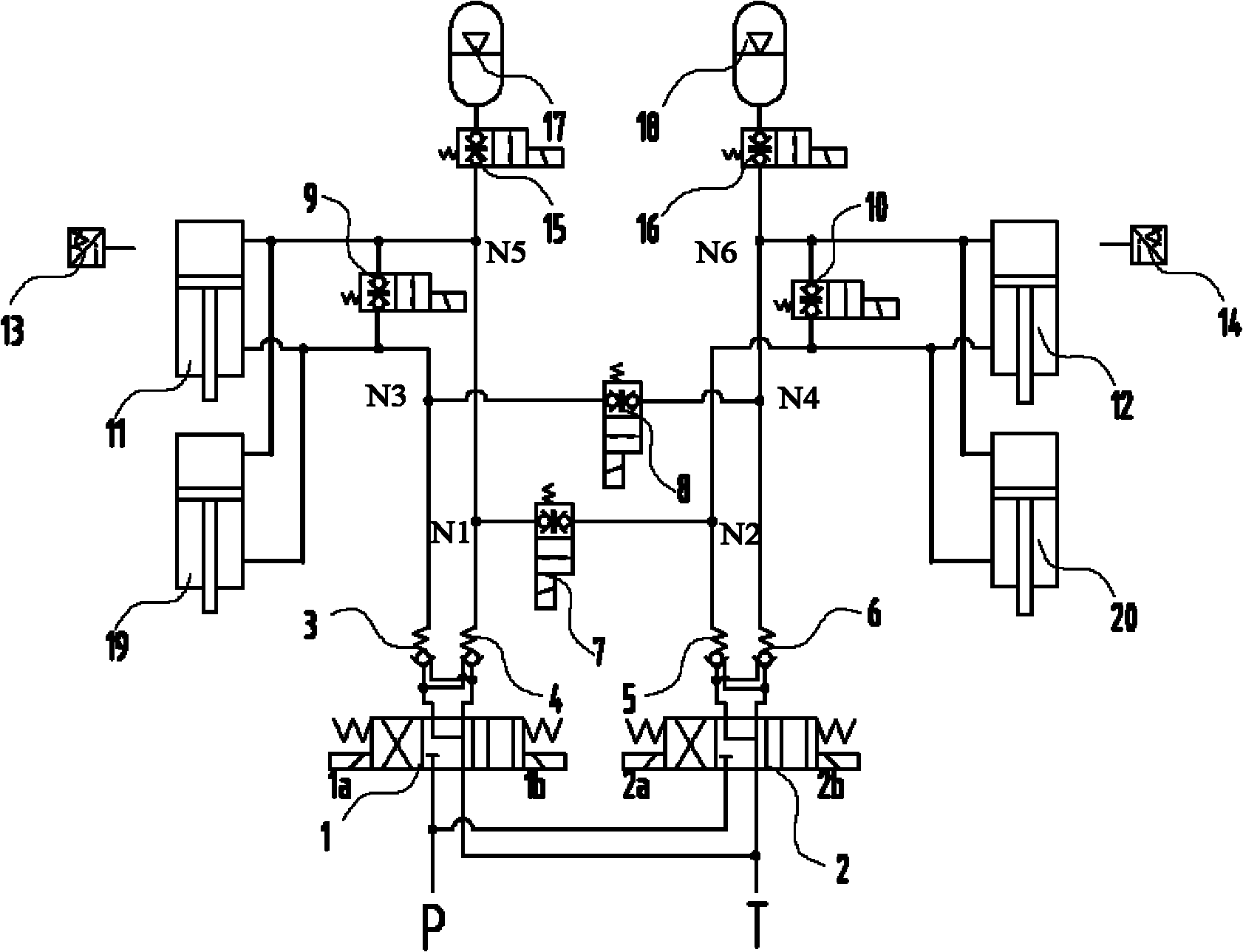

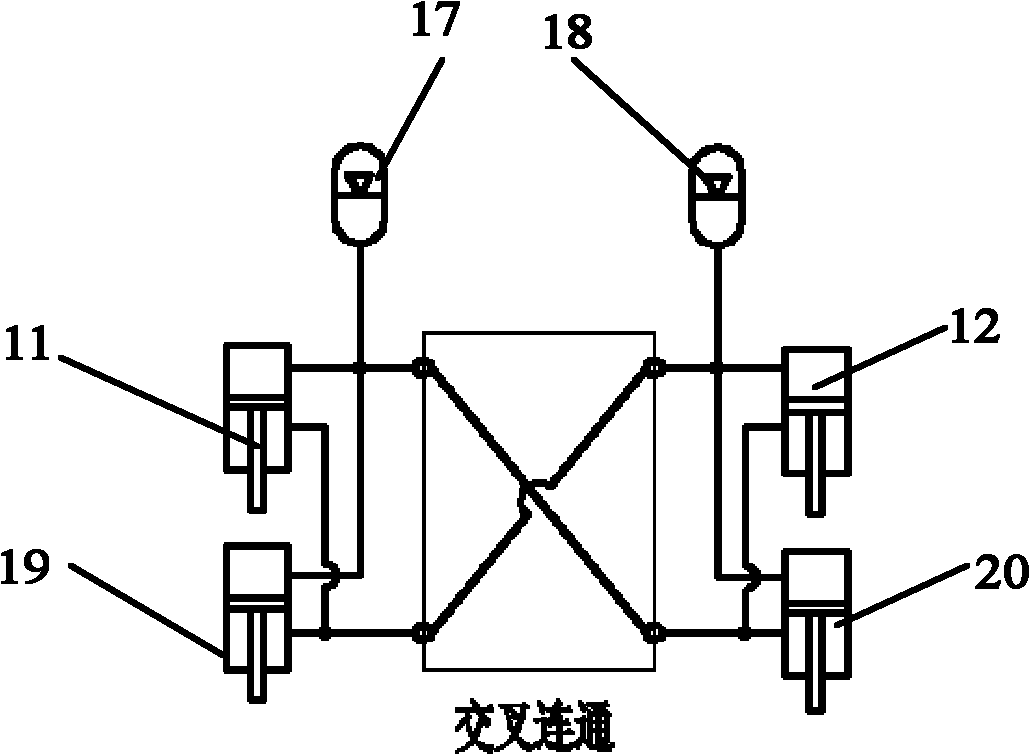

[0032] Such as figure 1As shown, it is a schematic diagram of the implementation of the hydraulic principle of single-axle suspension. The oil-pneumatic suspension device for wheeled vehicles provided in this embodiment includes a left reversing valve 1, a right reversing valve 2, a first hydraulic control check valve 3. The second hydraulic control check valve 4, the third hydraulic control check valve 5, the fourth hydraulic control check valve 6, the first on-off valve 7, the second on-off valve 8, the third on-off valve 9, The fourth on-off valve 10, the fifth on-off valve 15, the sixth on-off valve 16, the left hanging oil cylinder 11, the right hanging oil cylinder 12, the left accumulator 17, the right accumulator 18, and each oil circuit are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com