Explosive welding method for large-area lead-steel composite board

An explosive welding and large-area technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of interface melting and vaporization, soft lead hard to support, surface burns, etc., to increase the strength of the double board , realize the effect of large-area welding and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

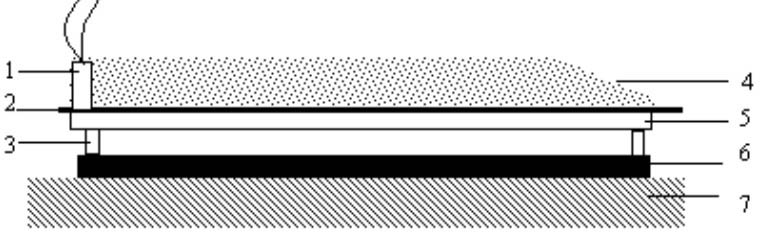

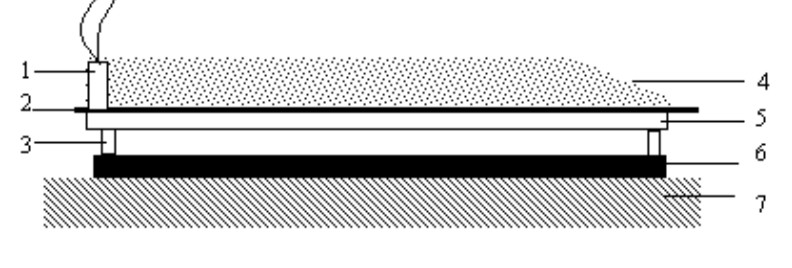

[0025] Such as figure 1 As shown: the base steel plate 6 and the double-layer lead plate 5 are polished with a polishing wheel or emery cloth to remove the metal oxide on the surface to expose the metallic luster, and the base steel plate 6 is placed on the clay foundation 7, and the double-layer lead plate 5 It is bonded with the metal plate 2 as a whole, and placed above the base steel plate through the support 3, and the explosive 4 is placed on the upper surface of the metal plate 2. Use No. 8 industrial electric detonator 1 to detonate, and obtain lead-steel composite board by explosive compounding. Based on the three embodiments of the present invention, better composite effects are obtained, see Table 1 for details.

[0026]

[0027] Table 1 is based on three embodiments of the present invention

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Detonation velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com