Mold core and preparation method thereof and method for producing casting inner cavity by using mold core

A technology of casting inner cavity and core, which is applied in the direction of core, casting molding equipment, casting mold, etc., to avoid deformation due to external force, good bending effect, and easy removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

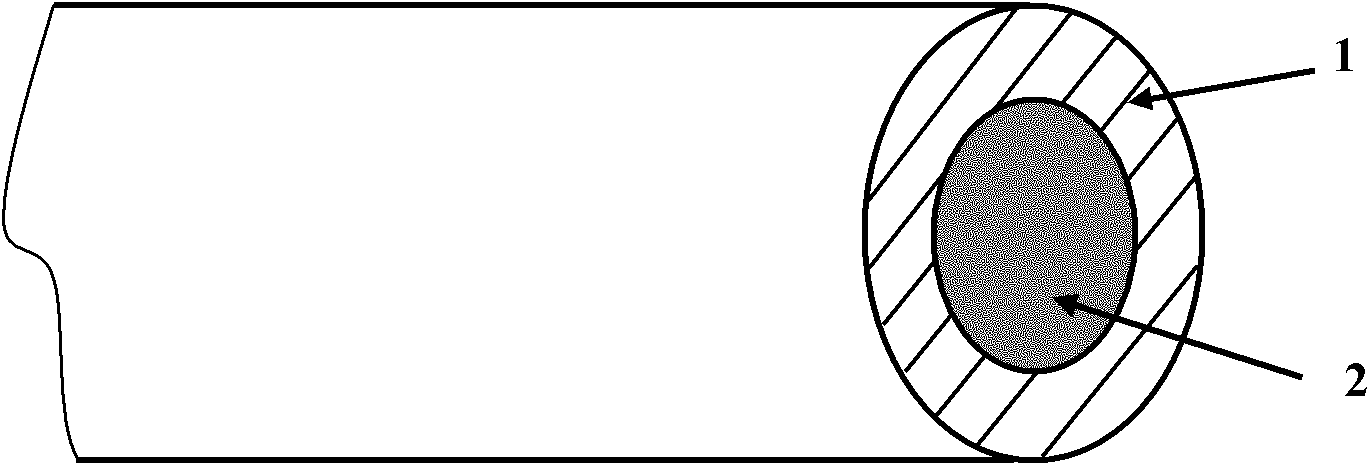

[0047] Example 1: This method is used to cast aluminum alloy shell castings of aviation fuel gear pumps. The casting material is ZL101, the pouring temperature is 710°C, the inner cavity is required to bear pressure, the minimum size of the inner cavity oil circuit is Ф4.2mm, and the diameter of one of the holes is Ф4.2mm fine-hole oil circuit, the overall shape is L-shaped, and the total length is 170mm; this example needs to use a brass tube with an outer diameter of Ф4.2mm, which is manufactured according to the preparation method of the brass tube core described in the content of the present invention. Example of the brass tube core required. Put the manufactured core into the cavity and combine it with the mold after being preheated by the core setting procedure, pour aluminum liquid into it to form a casting, and then remove the brass tube core according to the cleaning procedure in the above-mentioned casting inner cavity forming method , The brass tube core is removed ...

Embodiment 2

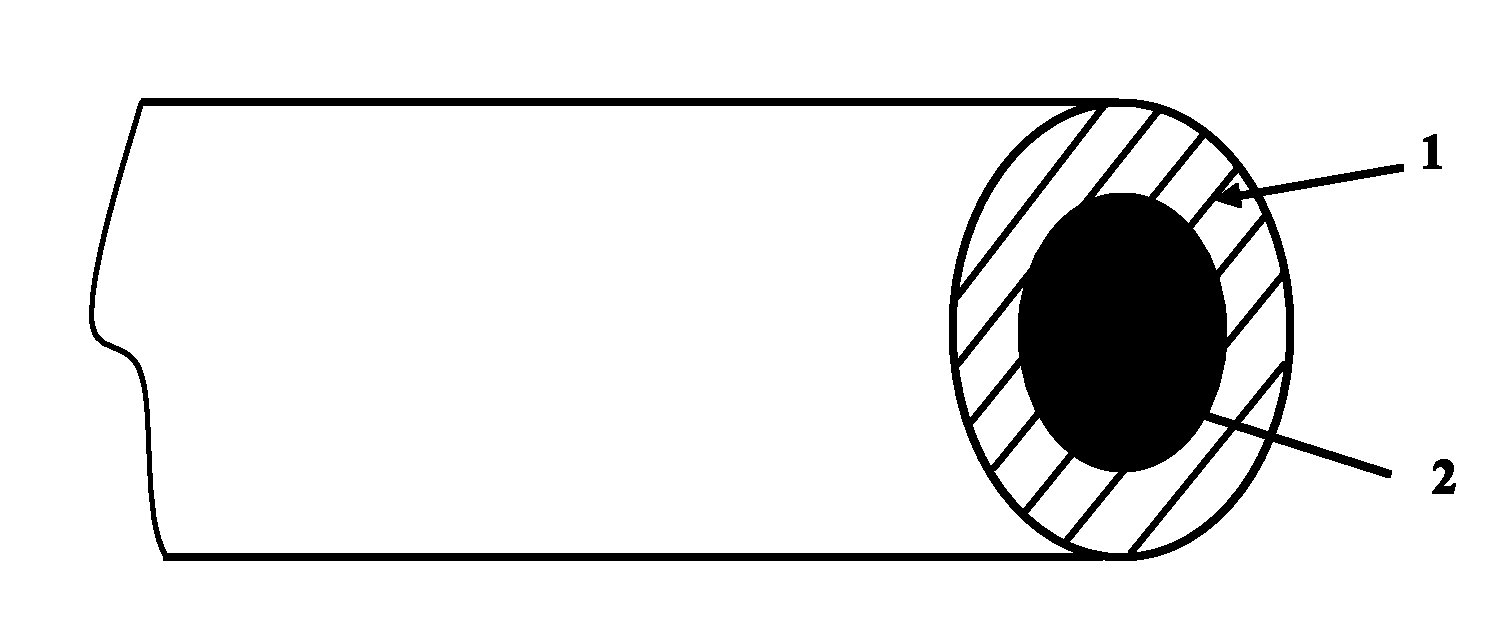

[0048] Example 2: Taking the casting of an aluminum alloy casting for a one-piece pump motor for a high-horsepower heavy vehicle as an example, the casting material is ZL105A, the pouring temperature is 720°C, the inner cavity is required to bear pressure, and one of the oil passages in the inner cavity has a diameter of Ф5mm and a length of 275mm. The O-shaped annular fine-hole oil passage intersects with an L-shaped oil passage with a diameter of Ф6.2mm and a length of 75mm. It is difficult to form it by using the sand core in the prior art. This embodiment requires two brass tubes of Ф5mm and Ф6.2mm, and the brass tube interlaced core required in this example is manufactured according to the preparation method of the brass tube core described in the content of the present invention. Put the prepared core into the mold cavity after preheating to combine with the mold, pour aluminum liquid to form a casting, and then remove the brass tube core with nitric acid according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com