Short and straight section row bending device of boiler diaphragm type wall

A membrane wall and top bending technology, which is applied in the manufacture of boiler membrane walls, can solve the problems of high material cost and waste of materials, and achieve the effect of reducing waste and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

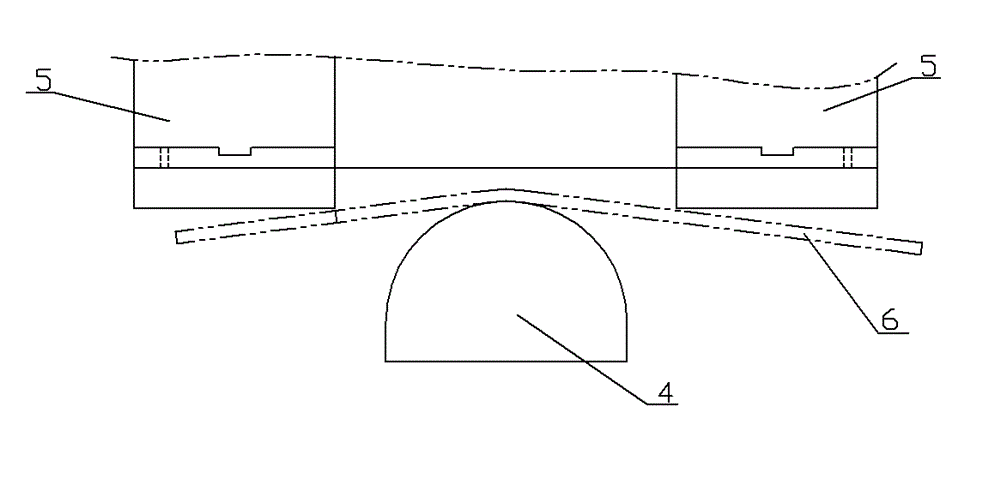

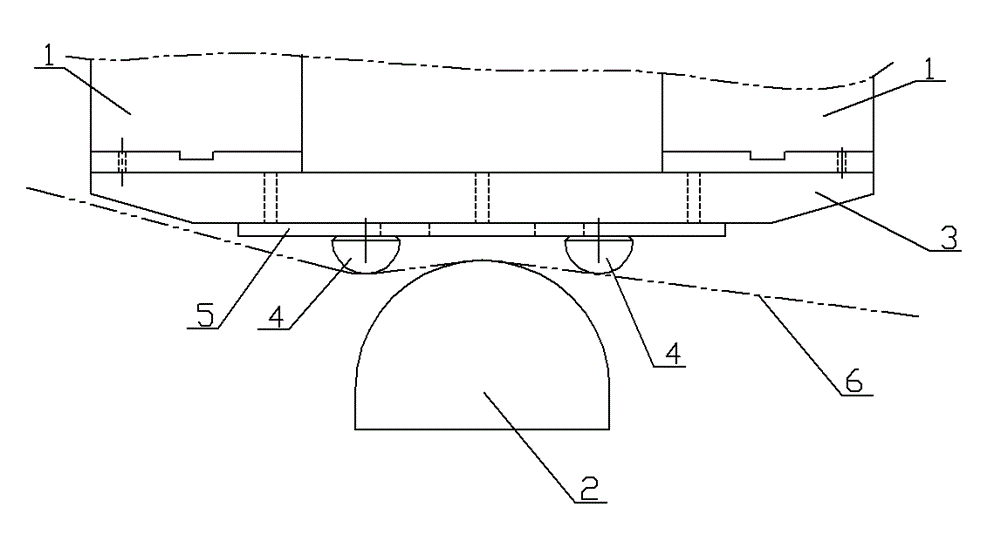

[0010] See image 3 , which includes side rollers 1 at both ends and a pressure roller 2 in the middle position, the top surface of the pressure roller 2 is an arc surface, and the end surfaces of the side rollers 1 at both ends close to the pressure roller 2 are tightly connected to the top bending support member 3, Both sides of the top bending support member 3 are respectively fastened to connect the side rollers 1 at both ends, and the both sides of the middle position near the end face of the top pressure roller of the top bending support member 3 are equipped with a forming semi-cylindrical wheel 4, and the circle of the forming semi-cylindrical wheel 4 The arc surface faces the top pressure roller 2, and a reinforcing rib 5 is fastened between the formed semi-cylindrical wheel 4 and the top bending support member 3. Figure 6 is the schematic structure of the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com