Fine granules having improved suspension performance in water

A fine-grained, hydrophilic technology, applied in the direction of organic active ingredients, medical preparations containing non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of not being able to suppress bitterness, and achieve excellent fine-grained, inhibiting The production of similar substances and the effect of improving suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

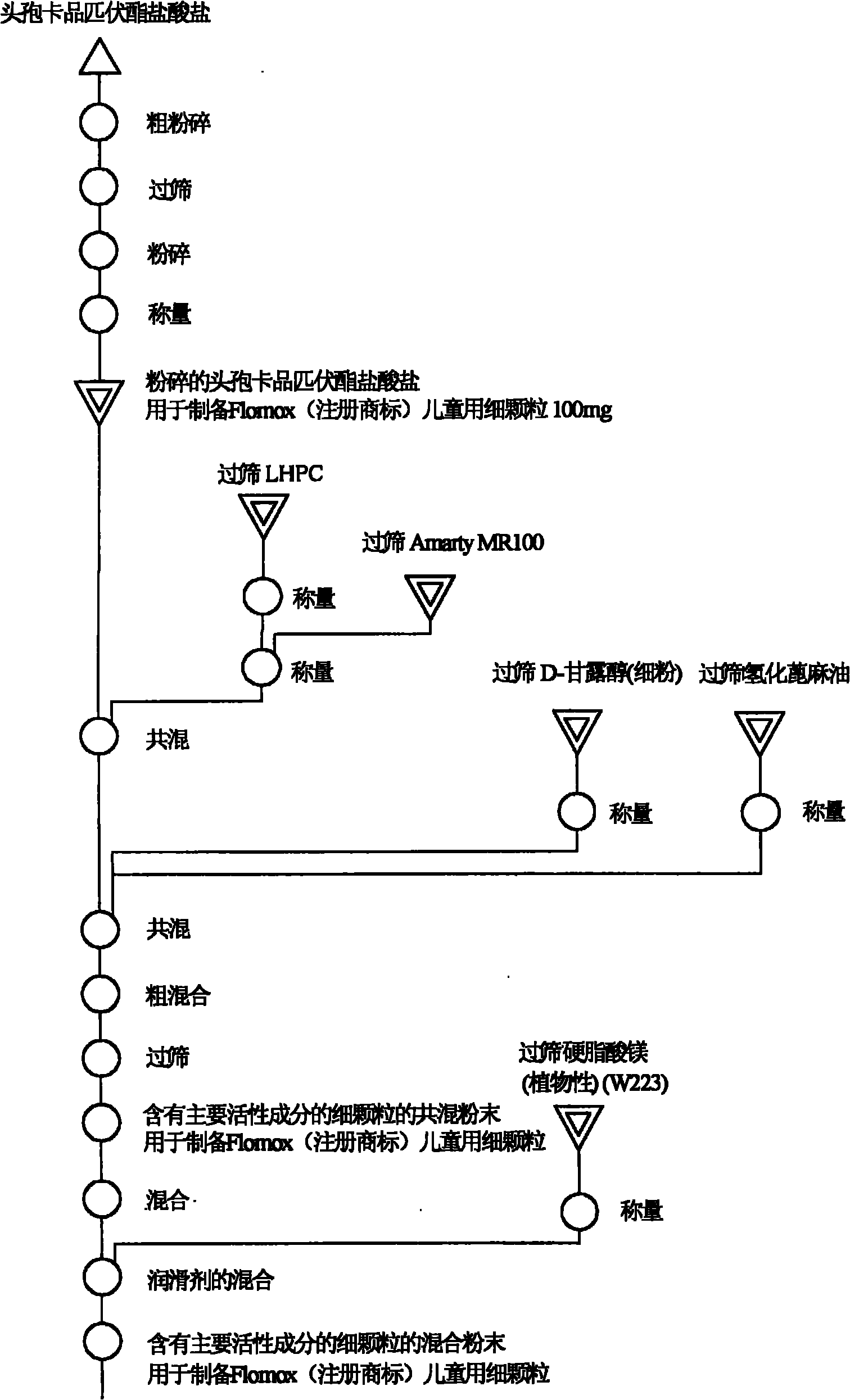

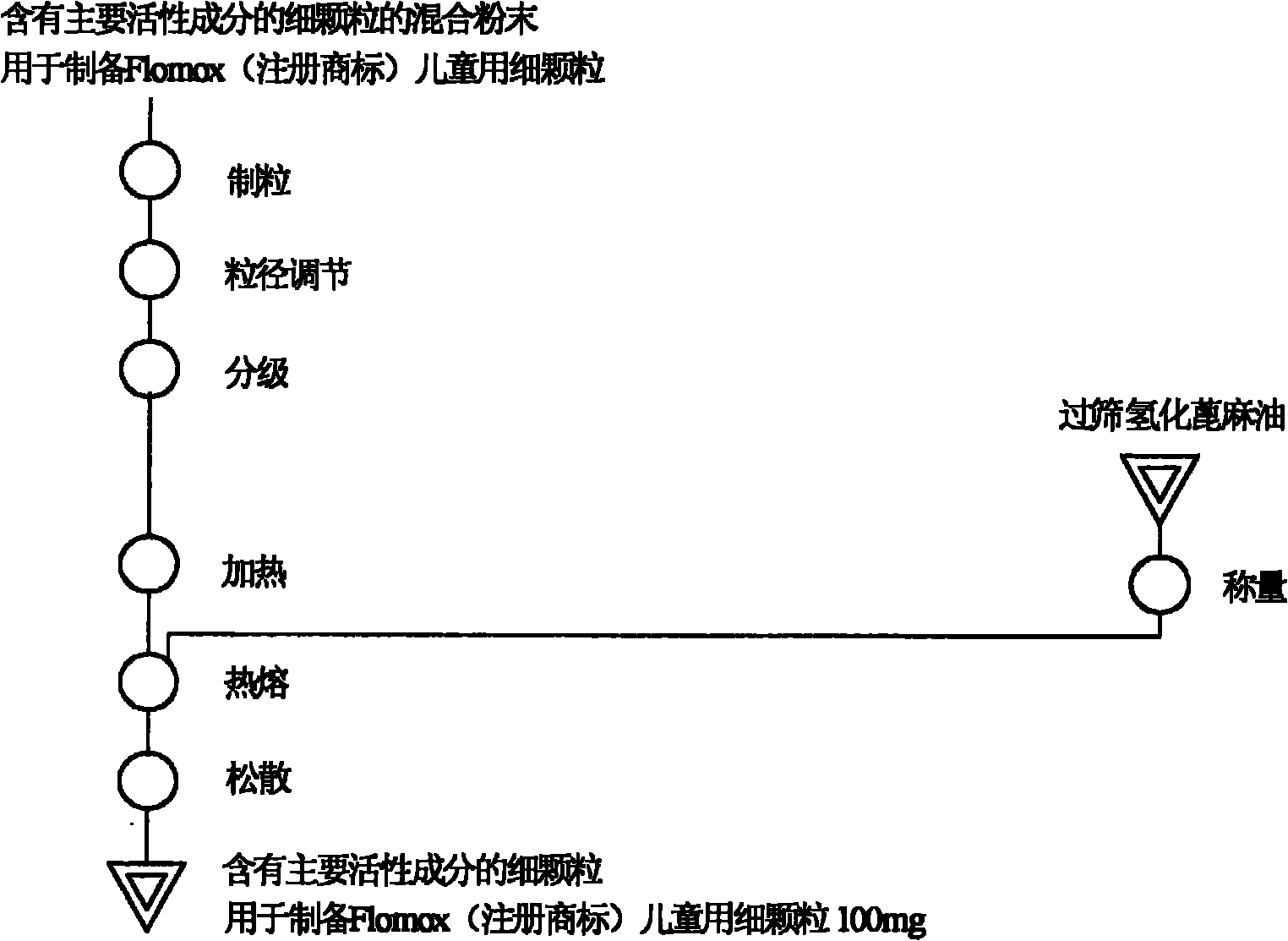

[0074] (1) Preparation of fine particles containing main active ingredients

[0075] First, about 40% by weight or less of a pharmaceutical compound, especially a pharmaceutical compound with an unpleasant taste; about 5 to about 25% by weight of a waxy substance; about 5 to about 35% by weight of a water-swellable substance; and Other additives such as binders, lubricants, sweeteners and coloring agents are required for mixing. The mixed powder is compressed to form flakes, and then the flakes are crushed. Next, the obtained particles are classified by a sieve, and the primary particles are obtained by adjusting the particle size to an optional particle size [granulation process].

[0076] All the materials used herein and the below-mentioned additives were subjected to the following treatments listed in Table 1 according to their properties in order to efficiently perform the mixing process.

[0077] [Table 1]

[0078]

[0079] Next, the primary particles are heated to...

Embodiment 1

[0091] (1) Preparation of fine granules containing main active ingredients and sweet fine granules

[0092] By the components listed in Table 2, according to the method recorded in the patent document (W02005 / 039538), that is, figure 1 with 2 process to prepare fine particles containing the main active ingredient. Sweet fine granules are also prepared according to the methods described in the above-mentioned patent documents.

[0093] Table 2

[0094]

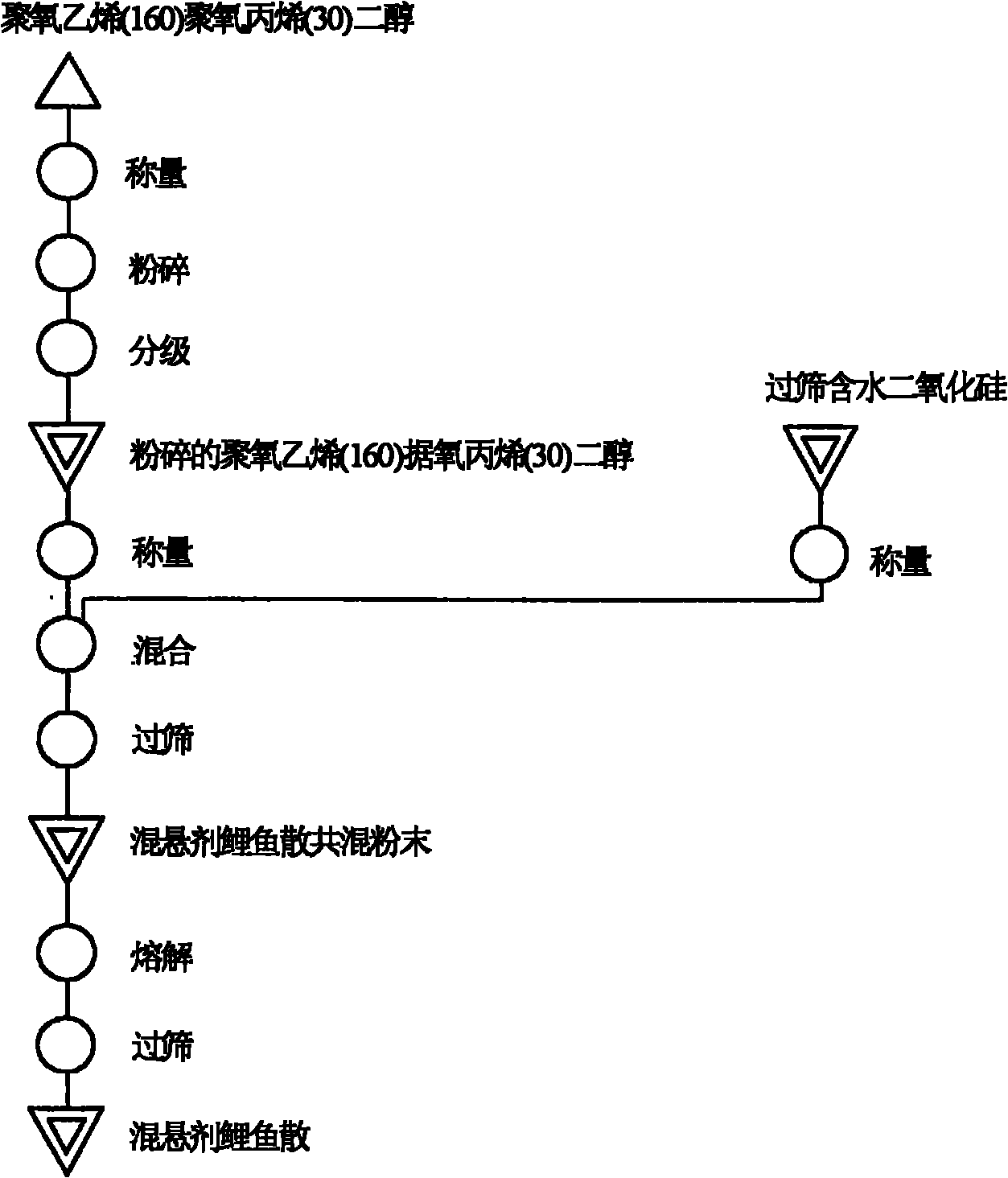

[0095] (2) Preparation of fine granules containing hydrous silicon dioxide or sodium lauryl sulfate

[0096] Powdered sodium lauryl sulfate was processed according to Table 1 above. Specifically, to obtain fine particles for blending, sodium lauryl sulfate was ground with an ultracentrifugal mill ZM200 (filter: 1 mm; rotation speed: low) so that the 50% average particle diameter was 50 μm or less. Next, as shown in Table 3 below, suspension Liyu powder was prepared by blending fine particles of sodium lauryl sulfate and...

Embodiment 4-6 and comparative Embodiment 2-3

[0101] Liquid or waxy surfactants are treated according to Table 1 above to obtain fine particles for blending. Next, according to Table 4 below, a predetermined amount of fine granules for blending was weighed and mixed in a bag with the fine granules containing the main active ingredient. Next, desired fine granules are produced by mixing the above-obtained granules with sweet fine granules, ferric oxide quintuplet and other additives in a bag.

[0102] [Table 4]

[0103]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com