Preparation method of lithium ion battery cathode material

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low energy density per unit volume of batteries, difficulty in ensuring batch stability, uneven distribution, etc., and achieve improved volumetric energy density , Improve batch stability, improve the effect of bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

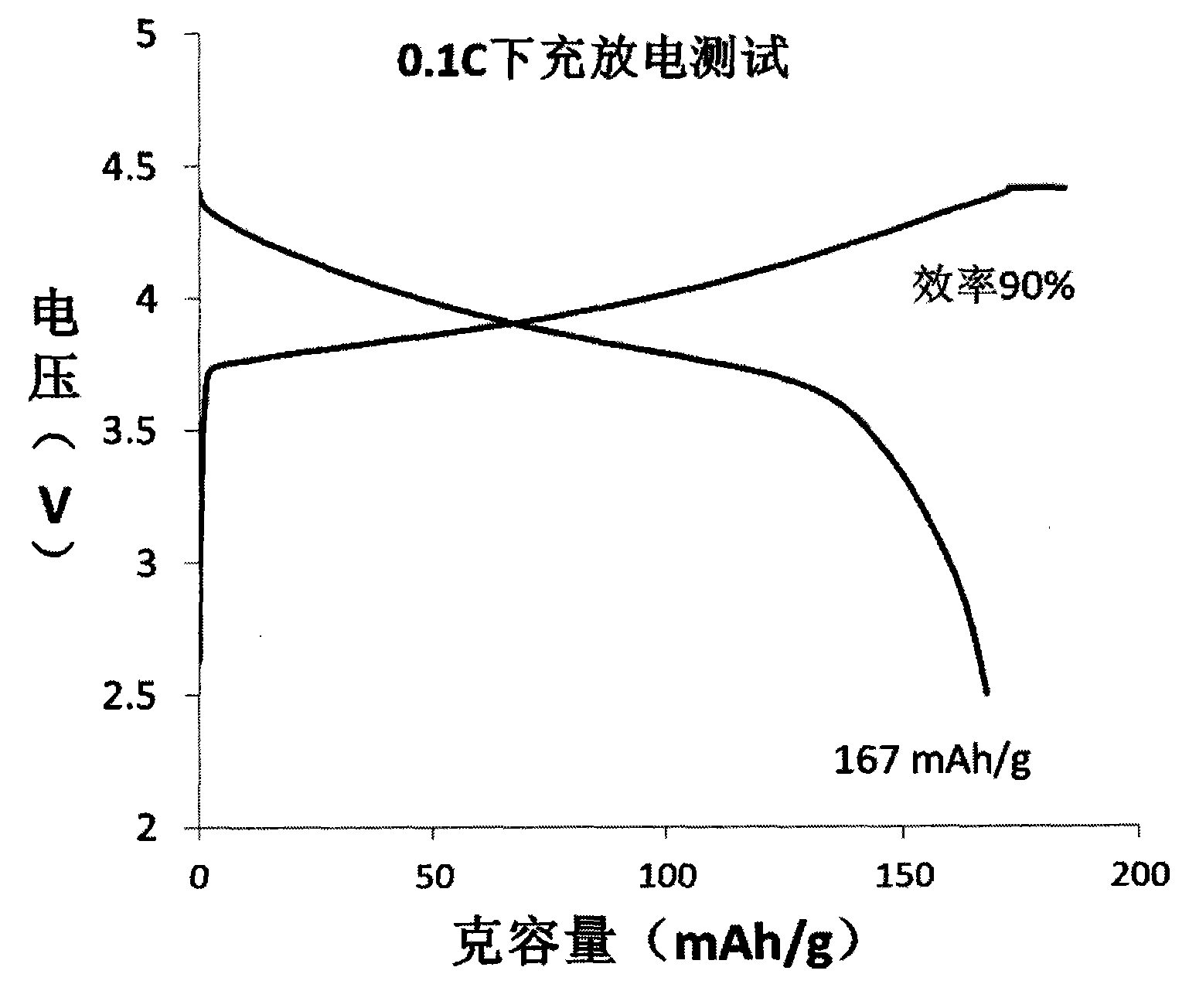

[0019] The lithium-ion battery cathode material prepared in this example is a three-component cathode material of lithium nickel manganese aluminate, and its chemical formula is LiNi 0.5-x mn 0.5-x al 2x o 2 , where x=0.025, that is, the chemical formula of the prepared lithium nickel manganese aluminum oxide three-component positive electrode material is LiNi 0.475 mn 0.475 al 0.05 o 2 .

[0020] The preparation method is as follows:

[0021] (1) 293.1g nickel nitrate hexahydrate, 170.3g manganese sulfate monohydrate, and 39.8g aluminum nitrate nonahydrate are dissolved in 1060ml water under stirring to form clarified nickel manganese with a total concentration of nickel, manganese and aluminum cations of 2.0mol / L Aluminum mixed solution;

[0022] (2) 276.6g of sodium carbonate is dissolved in 1300ml of water to form a 2.0mol / L clear solution (the excess coefficient of sodium carbonate is 1.2). Under vigorous stirring, slowly add sodium carbonate solution dropwise to ...

Embodiment 2

[0030] The lithium-ion battery cathode material prepared in this example is a three-component cathode material of lithium nickel manganese aluminate, and its chemical formula is LiNi 0.5-x mn 0.5-x al 2x o 2 , where x=0.01, that is, the chemical formula of the prepared lithium nickel manganese aluminum oxide three-component positive electrode material is LiNi 0.49 mn 0.49 al 0.02 o 2 .

[0031] The preparation method is as follows:

[0032] (1) 1366.4g nickel sulfate hexahydrate, 878.6g manganese sulfate monohydrate, and 79.6g aluminum nitrate nonahydrate are dissolved in 5300ml water under stirring to form clarified nickel manganese with a total concentration of nickel, manganese and aluminum cations of 2.0mol / L Aluminum mixed solution;

[0033] (2) 1362.8g of sodium carbonate is dissolved in 6430ml of water to form a 2.0mol / L clear solution (the excess coefficient of sodium carbonate is 1.2), and under vigorous stirring, slowly add sodium carbonate solution dropwise ...

Embodiment 3

[0041] The lithium-ion battery cathode material prepared in this example is a three-component cathode material of lithium nickel manganese aluminate, and its chemical formula is LiNi 0.5-x mn 0.5-x al 2x o 2 , where x=0.075, that is, the chemical formula of the prepared lithium nickel manganese aluminum oxide three-component positive electrode material is LiNi 0.425 mn 0.425 al 0.15 o 2 .

[0042] The preparation method is as follows:

[0043] (1) 1185.1g nickel sulfate hexahydrate, 762.1g manganese sulfate monohydrate, and 597.0g aluminum nitrate nonahydrate are dissolved in 5300ml water under stirring to form clarified nickel manganese with a total concentration of nickel, manganese and aluminum cations of 2.0mol / L Aluminum mixed solution;

[0044] (2) 1450.5g of sodium carbonate is dissolved in 6840ml of water to form a 2.0mol / L clear solution (the excess coefficient of sodium carbonate is 1.2), and under vigorous stirring, slowly add sodium carbonate solution dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com