High-pressure resistant oil and gas pipeline

A technology for oil and gas pipelines and high pressure resistance, which is applied in the field of natural gas pipes and oil transportation, can solve the problems of poor thermal insulation capacity of steel medium, shorten the service life of pipes, and reduce cost difficulties, so as to improve the transportation pressure, prolong the service life, and reduce the investment cost. and the effect of oil and gas transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

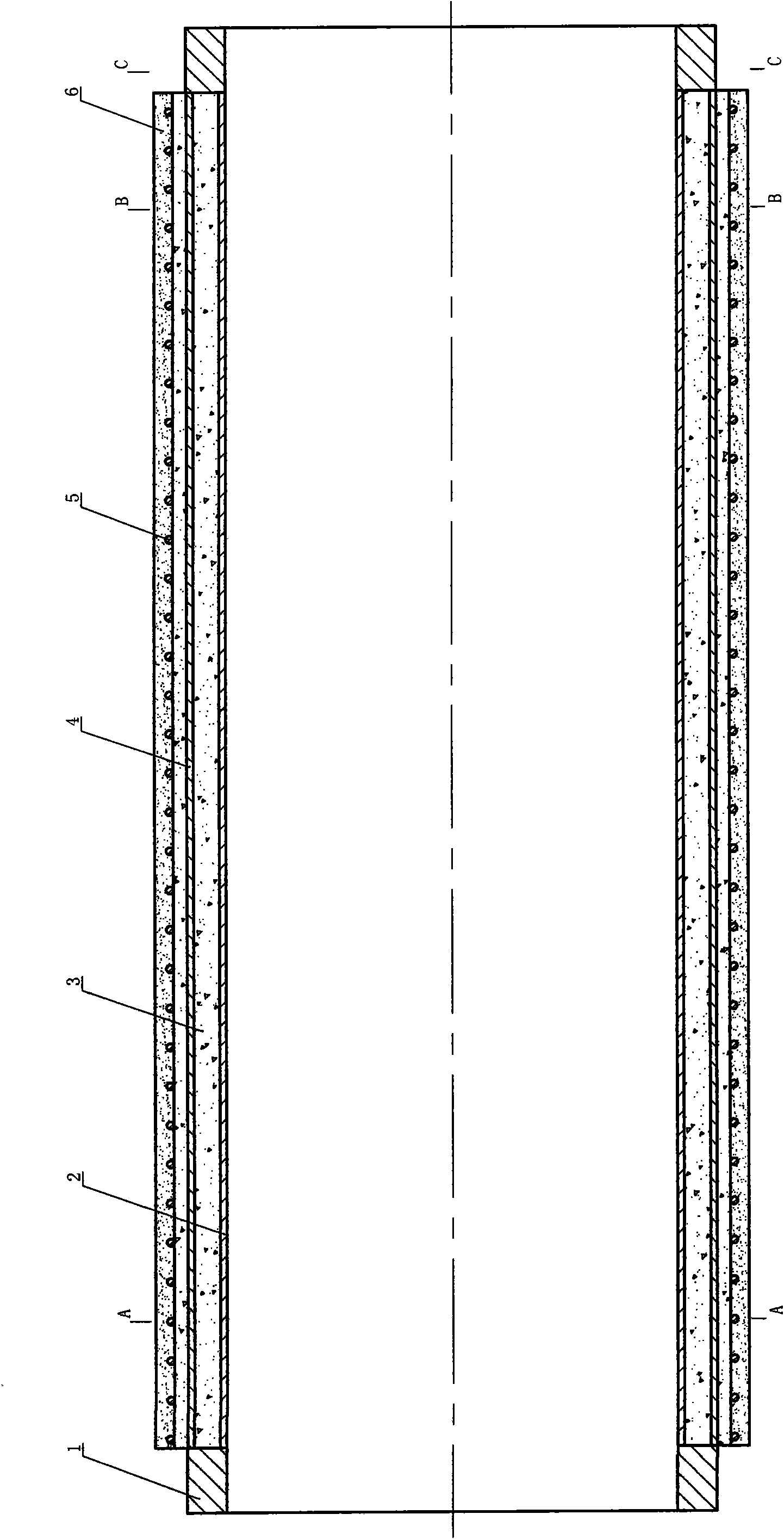

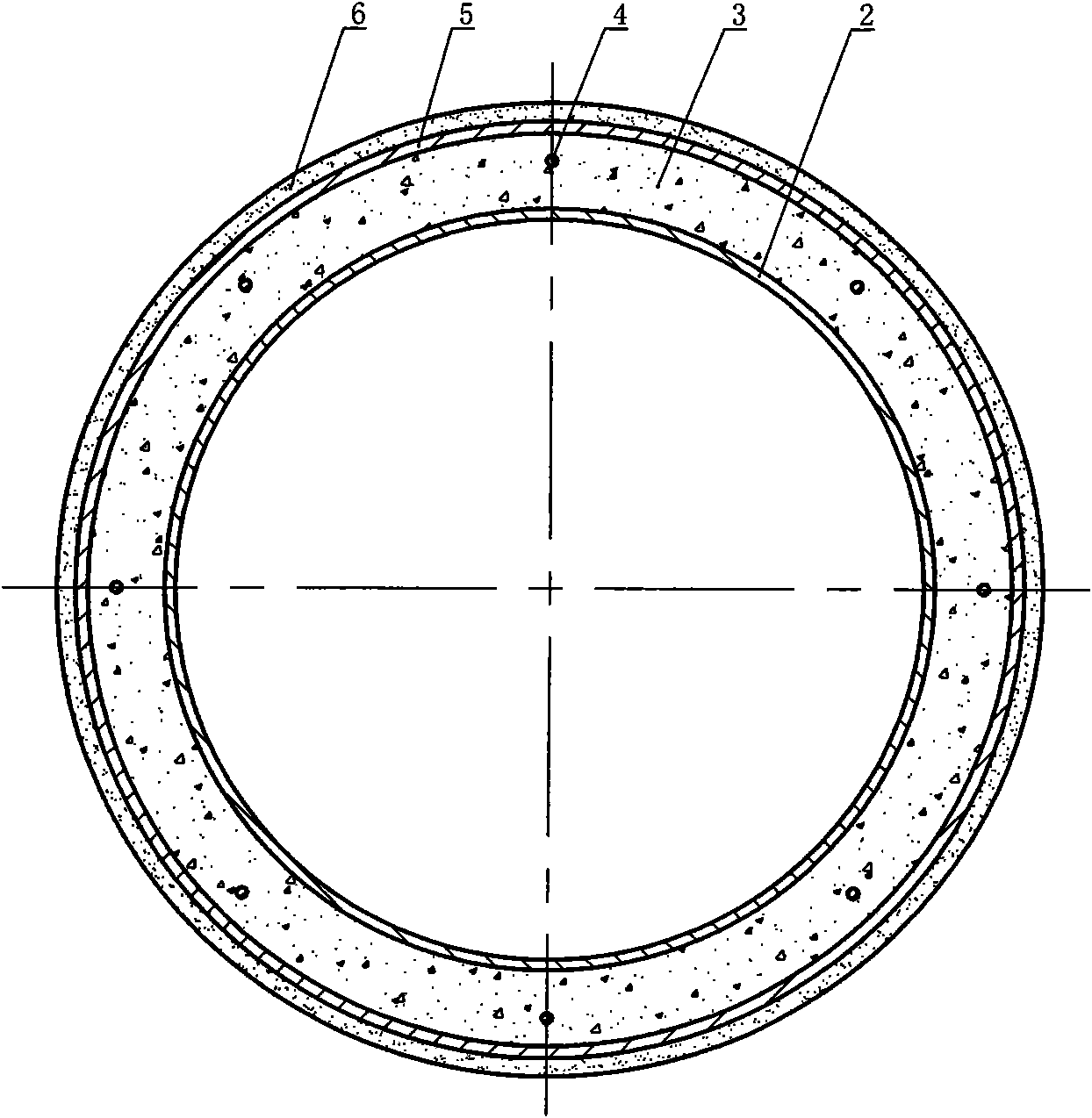

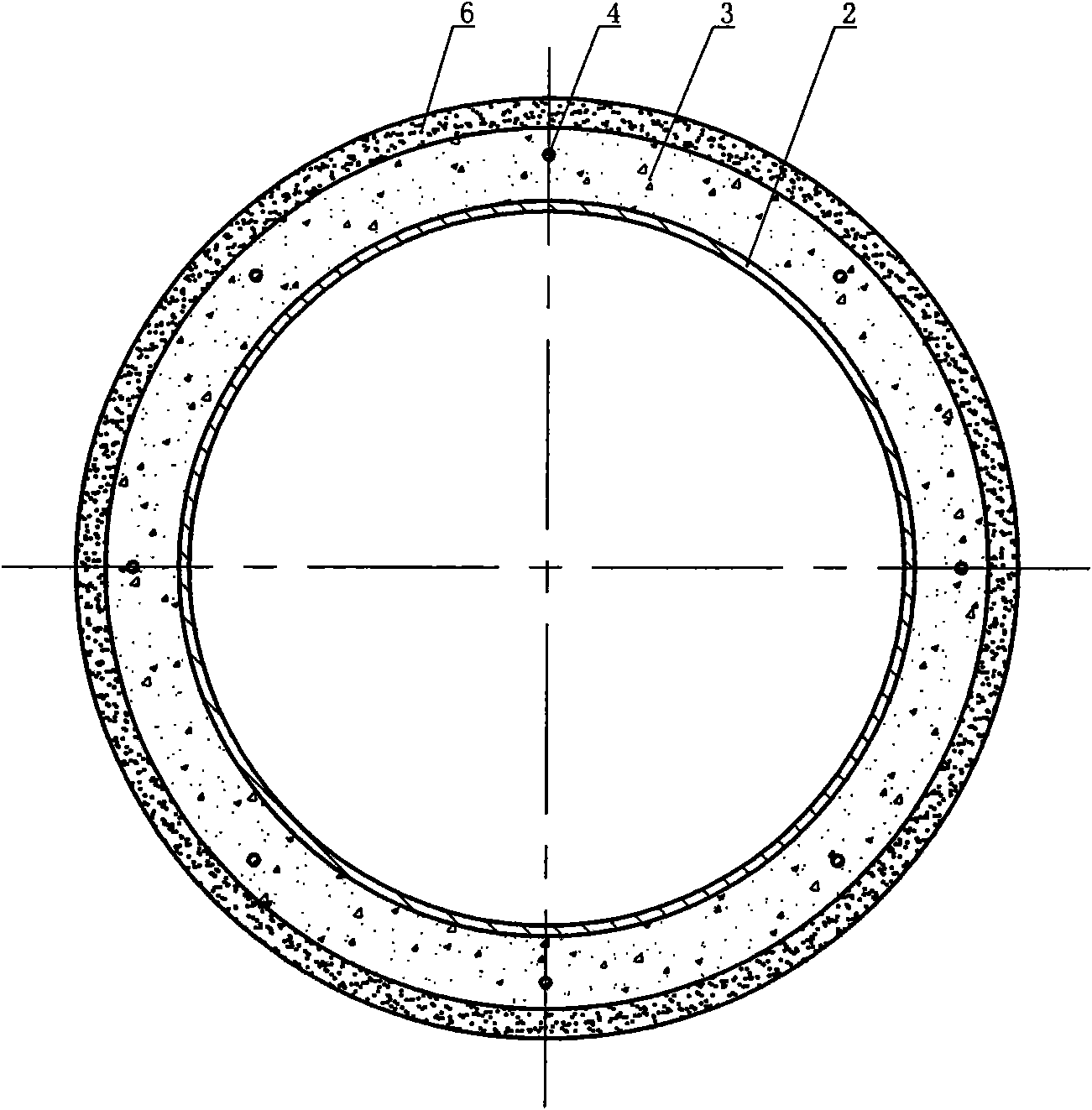

[0020] A prestressed concrete oil and gas pipeline, including a steel pipe 2, the steel pipe can be rolled and welded by Q235, X52, X65, X70, X80, X120 materials used for oil and gas pipelines, and the thickness is 2-50mm. Example steel pipe selection X70, the thickness is 8mm steel plate roll welding, the inner wall of the steel pipe can be coated with the liquid epoxy-based paint of the prior art, wherein a steel ring 1 is welded coaxially at the two ends of the steel pipe respectively, Between the two steel rings, the reinforcing bar skeleton 4 is coaxially fixed. The reinforcing bar skeleton can be made of longitudinal reinforcing bars and circumferential reinforcing bars, or can be made of N longitudinal reinforcing bars coaxially fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com