Dyed cotton spun-laced production process and product

A production process and technology of dyeing cotton, which is applied in the field of non-woven fabrics and can solve the problems of high cost and many dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

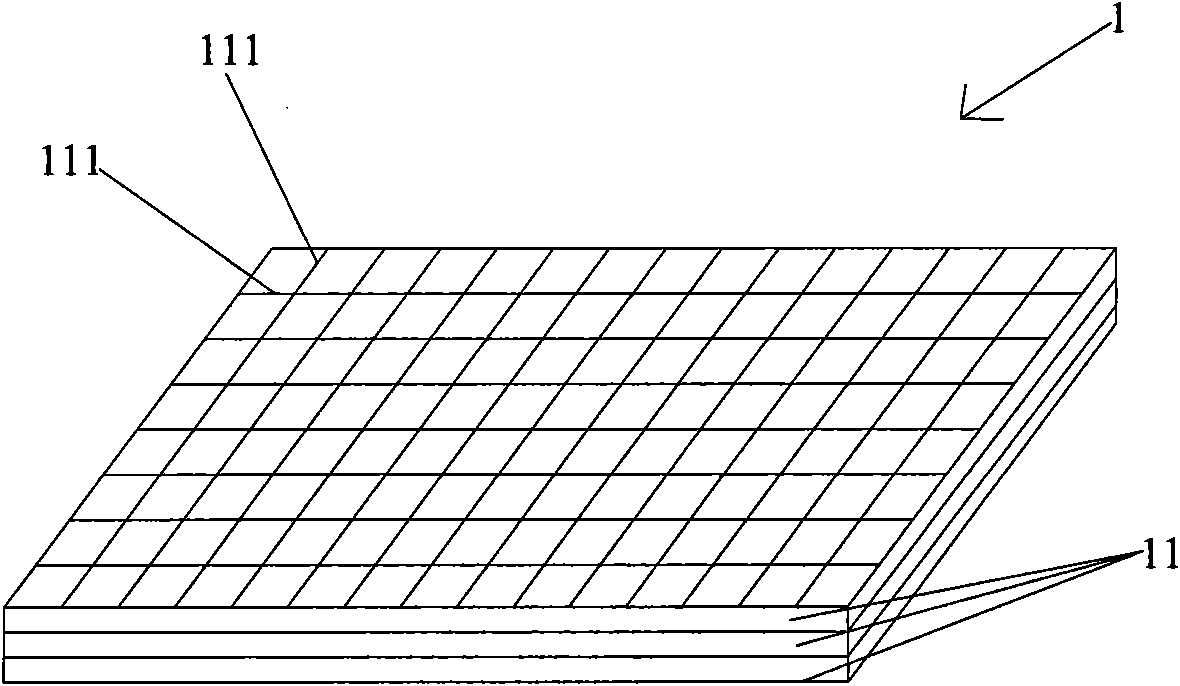

[0030] Such as figure 2 Shown is a dyed cotton spunlace product 1 provided by the present invention, which includes multiple layers of dyed cotton fibers 11, and each layer of dyed cotton fibers 11 is formed by intersecting single fibers 111 with mixed colors.

[0031] Such as figure 1 As shown, the present invention simultaneously provides a production process for producing the above-mentioned dyed cotton spunlace product 1, comprising the following process steps:

[0032] (1) Raw material preparation: Raw cotton, that is, pure natural seedless lint cotton, is prepared for use.

[0033] (2) Blowing: Utilize the cleaning machine to remove impurities and defects in the raw cotton. This step is a known technology and is the same as the prior art.

[0034] (3) Degreasing: wax and grease on the cotton fibers are removed to enhance the water absorption of the cotton fibers. This step is the same as the degreasing process in the prior art.

[0035] (4) Bleaching: to obtain bleac...

Embodiment 2

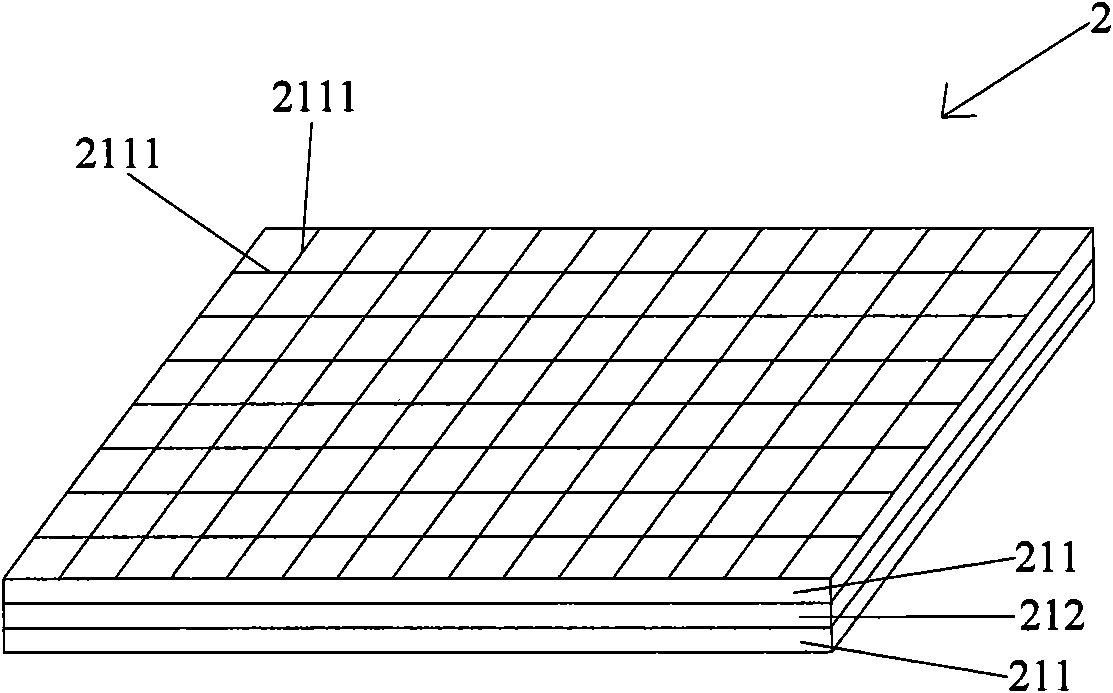

[0045] Such as image 3 Shown is another dyed cotton spunlace product 2 provided by the present invention, which includes multiple layers of dyed cotton fibers 21, each layer of dyed cotton fibers 21 is a different color, and the cotton fibers of different colors are alternately stacked at intervals. In this embodiment, the dyed cotton fibers 21 include white cotton fibers 211 and red cotton fibers 212, wherein the red cotton fibers 212 are placed between two layers of white cotton fibers 211, and the white cotton fibers 211 are composed of white single fibers 2111 The red cotton fibers 212 are formed by crossing each other, and the red cotton fibers 212 are formed by crossing red single fibers (not shown).

[0046] The present invention simultaneously provides a production process for producing the above-mentioned dyed cotton spunlace product 2, comprising the following process steps:

[0047] (1) Raw material preparation: Raw cotton, that is, pure natural seedless lint cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com