Supported imidazole ion liquid cross-linked polymer nano particles and preparation and application thereof

A technology of imidazole ionic liquid and cross-linked polymer, which is applied in the chemical field, can solve the problems of low catalytic activity and selectivity, toxic co-solvent or co-catalyst, low catalyst stability, etc., and achieves simple preparation method, mild reaction conditions, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

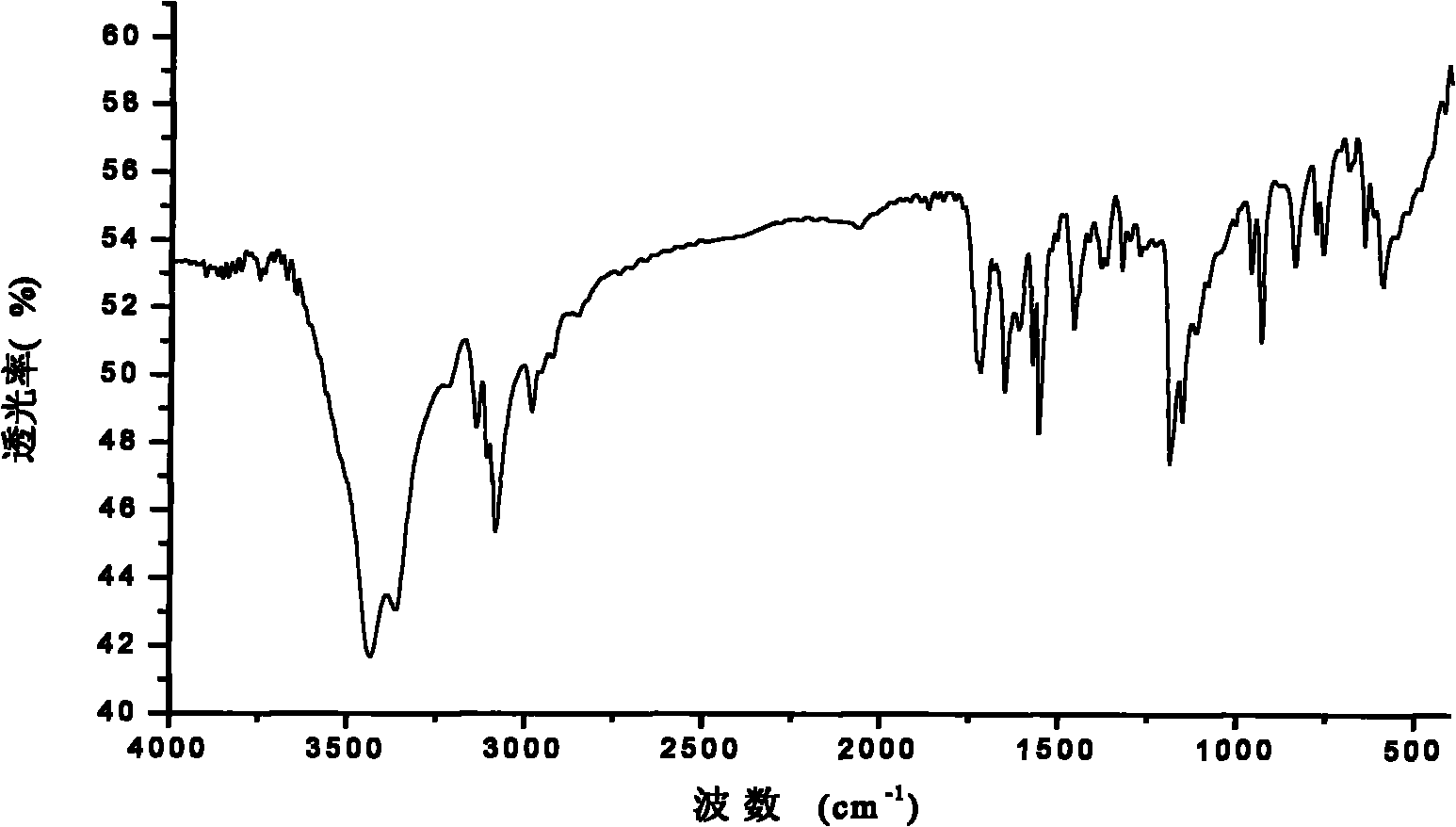

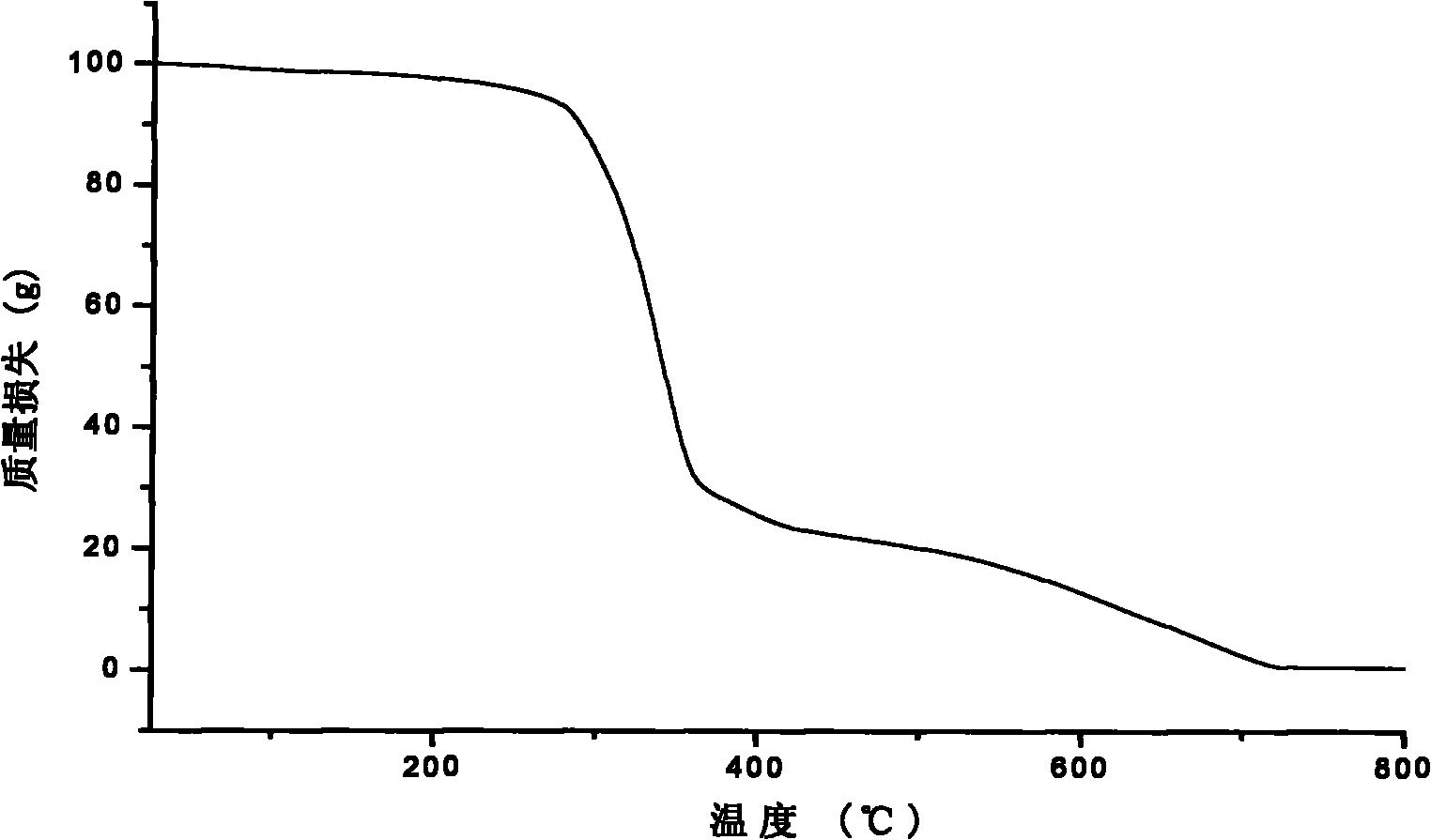

[0043] Example 1. Preparation of supported imidazole ionic liquid cross-linked polymer nanoparticles (CLPN)

[0044] (1) Synthesis of biimidazolium bromide ionic liquid ([DIMB]Br)

[0045] Mix 1-vinylimidazole (4.00g, 42.5mmol) and 1,4-dibromobutane (4.75g, 22mmol) at a molar ratio of 2:1, add them to a 100ml round bottom flask, and then add 50ml methanol, In N 2 Protect, stir and reflux at 70℃ for 48h. After the completion of the reaction, the mixture was poured into 150 ml of ether to settle and filter, and the product was placed in a vacuum drying cabinet to dry at room temperature for 24 hours to obtain biimidazolium bromide ionic liquid ([DIMB]Br). Yield: 65.6%.

[0046] (2) Preparation of copolymer of biimidazole bromide ionic liquid and crosslinker divinylbenzene (DVB)

[0047] [DIMB]Br (1.58g, 3.92mmol) was mixed with cross-linking agent DVB (0.26g, 1.96mmol), added to a 100ml round bottom flask, and then 50ml of methanol and AIBN (0.021g, 0.013mmol) were added. In N 2 Prot...

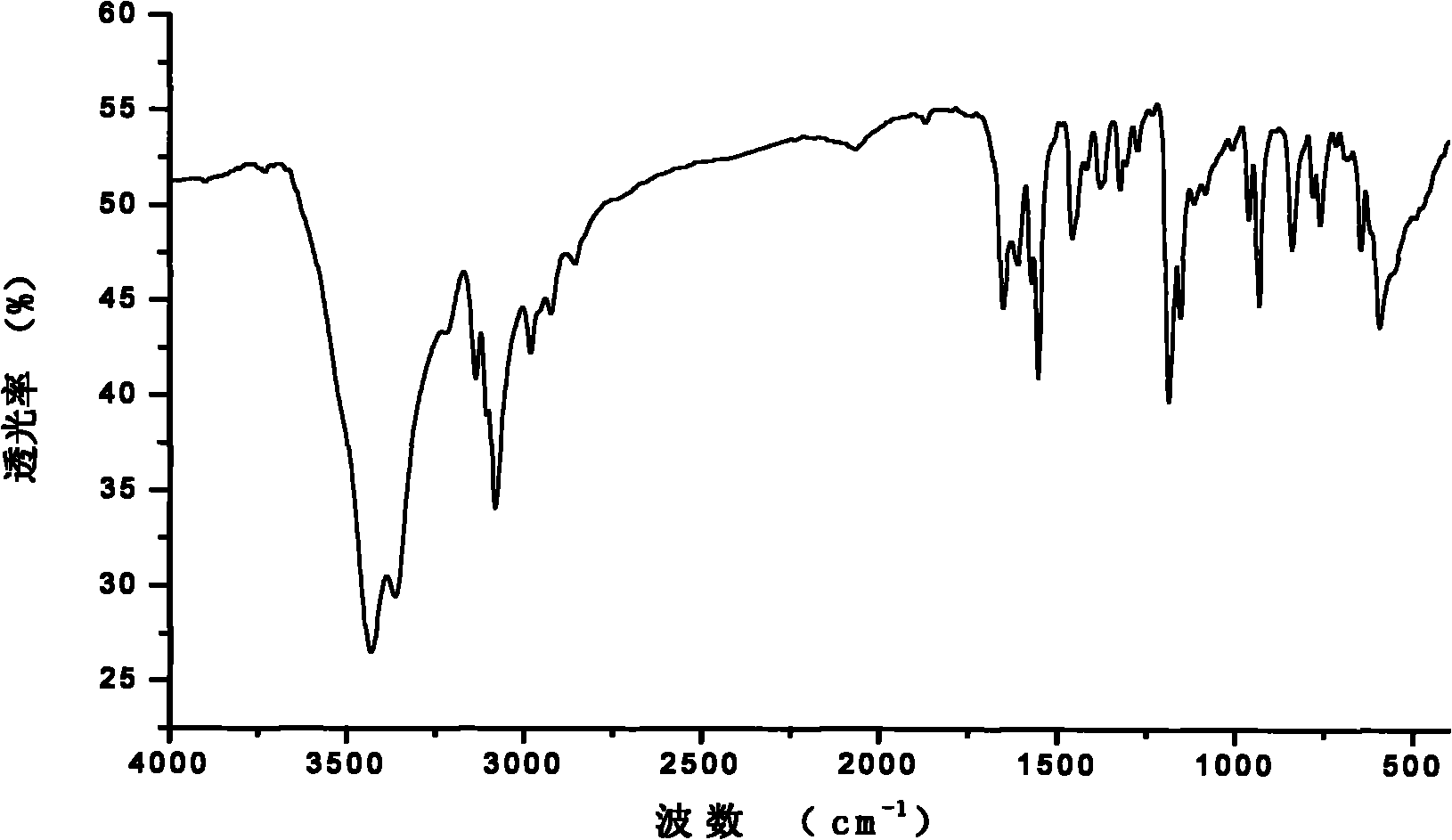

Embodiment 2

[0049] (1) Synthesis of biimidazolium bromide ionic liquid ([DIMB]Br)

[0050] Mix 1-vinylimidazole (4.00g, 42.5mmol) and 1,4-dibromobutane (4.75g, 22mmol) at a molar ratio of 2:1, add them to a 100ml round bottom flask, and then add 50ml methanol, In N 2 Protect, stir and reflux for 48h at 70°C. After the completion of the reaction, the mixture was poured into 150 ml of ether to settle and filter, and the product was placed in a vacuum drying cabinet to dry at room temperature for 24 hours to obtain biimidazolium bromide ionic liquid ([DIMB]Br). Yield: 65.6%.

[0051] (2) Preparation of copolymer of biimidazole bromide ionic liquid and crosslinker divinylbenzene (DVB)

[0052] Mix [DIMB]Br (1.98g, 4.9mmol) and crosslinking agent DVB (0.13g, 0.98mmol), add them to a 100ml round bottom flask, then add 50ml of methanol and AIBN (0.021g, 0.013mmol), N 2 Protect, stir and reflux for 24h at 70°C. After the reaction, it was cooled to room temperature, settled in ether and filtered. The...

Embodiment 3

[0054] (1) Synthesis of biimidazolium bromide ionic liquid ([DIMB]Br)

[0055] Mix 1-vinylimidazole (4.00g, 42.5mmol) and 1,4-dibromobutane (4.75g, 22mmol) at a molar ratio of 2:1, add them to a 100ml round bottom flask, and then add 50ml methanol, In N 2 Protect, stir and reflux for 48h at 70°C. After the completion of the reaction, the mixture was poured into 150 ml of diethyl ether to settle and filter, and the product was placed in a vacuum drying cabinet to dry at room temperature for 24 hours to obtain biimidazolium bromide ionic liquid ([DIMB]Br). Yield: 65.6%.

[0056] (2) Preparation of copolymer of biimidazole bromide ionic liquid and crosslinker divinylbenzene (DVB)

[0057] Mix [DIMB]Br (2.18g, 5.4mmol) and crosslinking agent DVB (0.07g, 0.54mmol), add it to a 100ml round bottom flask, then add 50ml of methanol and AIBN (0.021g, 0.013mmol), in N 2 Protect, stir and reflux for 24h at 70°C. After the reaction, it was cooled to room temperature, settled in ether and filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com