Method for preparing selective microbial packing

A biological filler and selective technology, applied in separation methods, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of reducing the treatment efficiency of desulfurization process, increasing the growth rate of dehydrocarbon bacteria, and poisoning desulfurization bacteria, etc. The effect of shortening the acclimation period, reducing the acclimation time, and increasing the biomass of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of selective biofiller of the present invention specifically comprises the following steps:

[0015] (1) Select plant fibers with a low degree of carbonization or a mixture of plant fibers and activated carbon as the basic biological filler in fertile land;

[0016] (2) Screen and isolate the obligate desulfurization bacteria group from the activated sludge in the sewage field of the factory area, and after purification, multiply and cultivate it in a large number in the nutrient solution to prepare the mother liquid of the desulfurization bacteria;

[0017] (3) leaching with nutrient solution and regularly spraying the basic biological filler to obtain a micro-ecological environment suitable for the growth of desulfurization bacteria;

[0018] (4) Spray the desulfurization mother liquor on the basic biological filler dipped in the nutrient solution to obtain the biological filler for selectively removing sulfide.

[0019] The plant organic fiber...

Embodiment 1

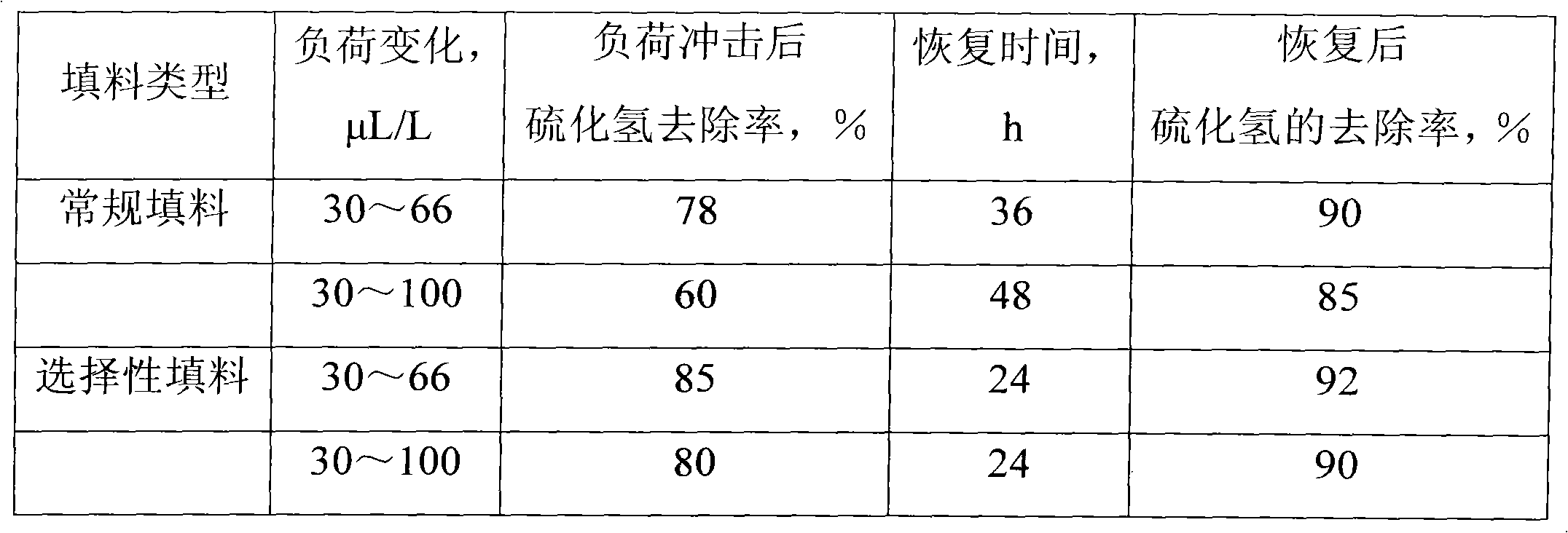

[0027] The A / O pool of the sewage treatment plant in the refinery often escapes malodorous gases such as hydrogen sulfide. Due to the influence of fluctuations in the inflow and outflow of the A / O pool, water temperature and other working conditions, the use of selective biological fillers can better adapt to the processing load. Fluctuation, to purify the malodorous gas.

[0028] The selective biological filler is filled in the microbial purification process device, and the preparation method of the selective biological filler is as follows:

[0029] The activated sludge taken from the A / O pool of the sewage treatment plant was placed in a shaker at 32°C (180r min -1 ) after shaking culture for 48 hours, select MLSS has reached 1000mg·L -1 The above culture solution was placed in selective medium (Na 2 S 2 o 3 ·5H 2 O 50.0g, KH 2 PO 4 20.0g,K 2 HPO 4 20.0g, MgSO 4 ·7H 2 O 4.0g, NH 4 Cl 2.0g, distilled water 5000mL, adjust the pH to about 7.0 with NaOH, add 0.3% ...

Embodiment 2

[0036] In the preparation process described in Example 1, the basic filler was replaced with a mixed basic filler with a volume ratio of peat and activated carbon of 4:1. The soaking of the basic filler and the spraying method of the nutrient solution are the same as in Example 1. Prepare 5.0w% sodium phosphate and 3.0w% potassium phosphate inorganic salts, 2.0w% sodium thiosulfate, and NO 3- , Mg 2+ and other nutrients. Use the prepared nutrient solution to spray the nutrient salt on the basic filler every 2.5 hours, keep its humidity in the range of 30-70%, dilute the desulfurization mother solution and spray it on the basic biological filler soaked in the nutrient solution, at 30 Under the condition of ℃ to 36 ℃, after 24 to 36 hours, a biological filler for selectively removing sulfide can be obtained.

[0037] Table 2 Physical properties of biological fillers for selective removal of sulfide

[0038] specific surface area

[0039] Apply the selective packing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com