Sewage treatment method for circulating cooling water system

A technology of circulating cooling water and treatment method, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of reducing Cl- and heterotrophic bacteria content, complex process and so on , to achieve the effect of low cost, reduced corrosion rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

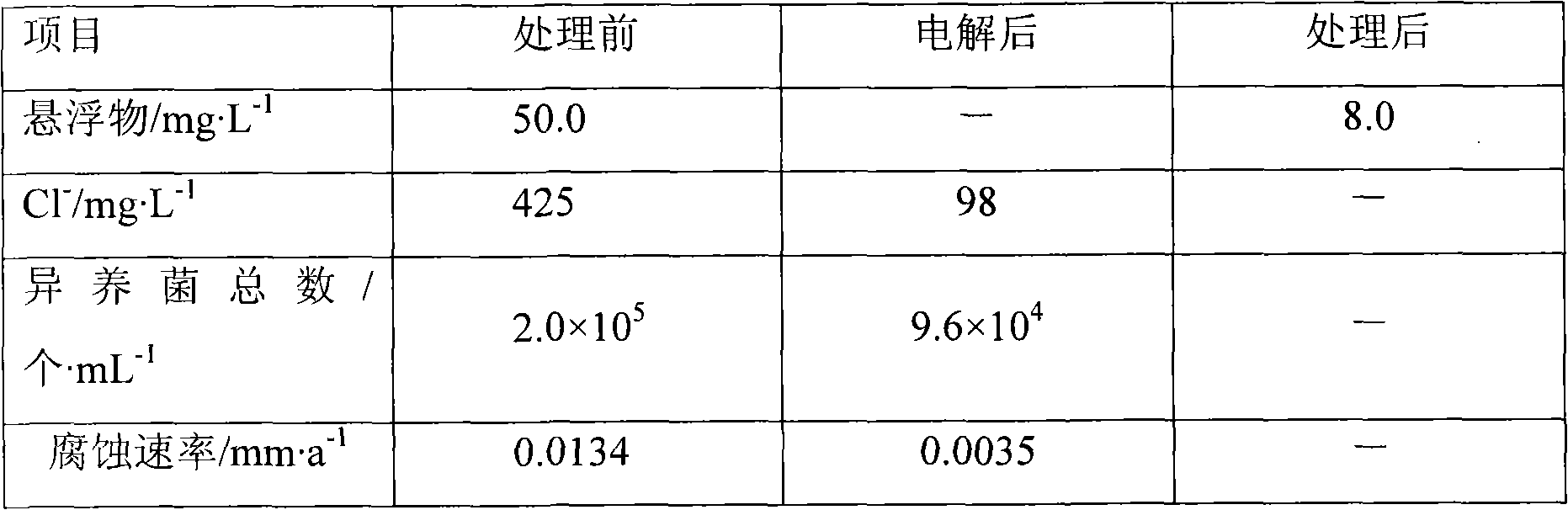

[0032] The sewage from the circulating water system of a power plant, Cl - High content (cations are mainly Na + , Ca 2+ , Mg 2+ ), its composition before processing is as shown in Table 1. Adopt the electrolysis method of the inventive method to process, the size of the electrolyzer is 5m * 2m * 2m, install 5 pairs of series electrode plates in the electrolyzer, anode and cathode base material are all titanium, the surface is plated with platinum, each electrode plate area 2m 2 , the voltage of each pair of electrode plates is 2.5V; electrolysis for 15min, analysis of Cl after electrolysis - Concentration, total number of heterotrophic bacteria and corrosion rate, the results are shown in Table 1.

[0033] Table 1

[0034] project

Embodiment 2

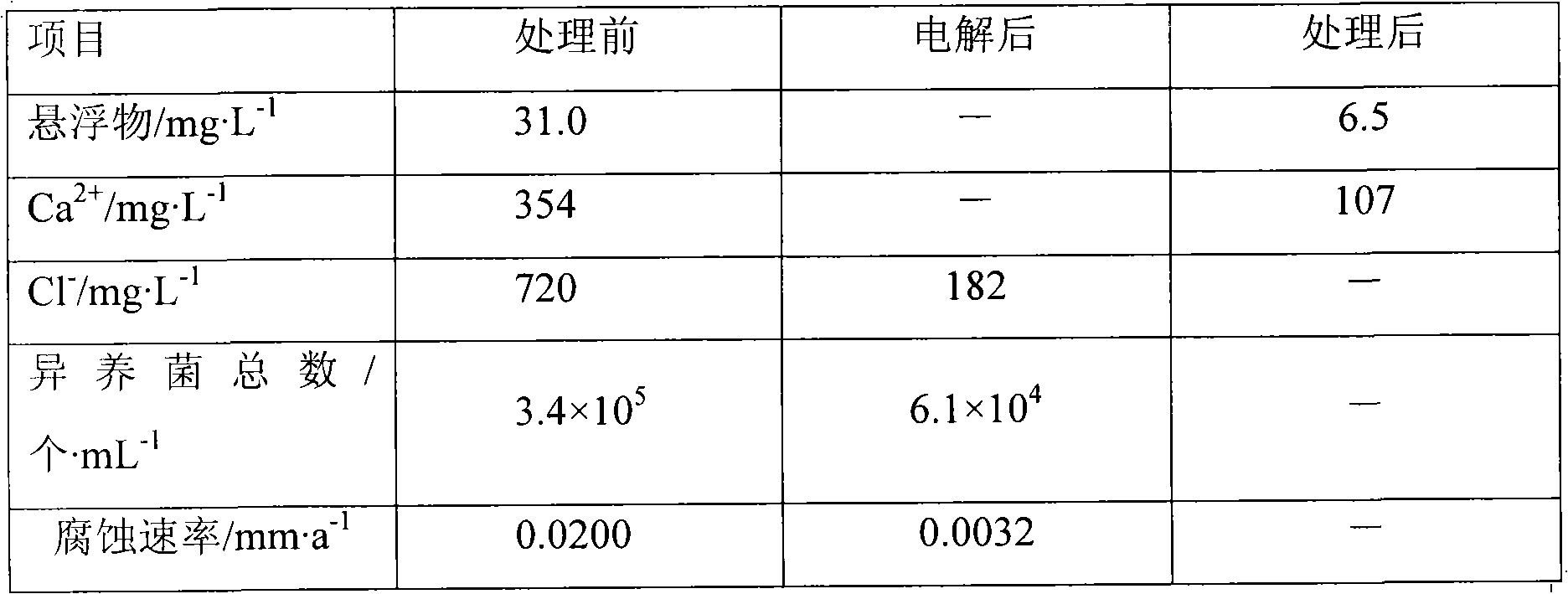

[0036] The sewage from the circulating water system of a power plant, Cl - and Ca 2+ The content is high, and its composition before treatment is as shown in table 2, adopts the method of the present invention to carry out electrolysis, and the size of electrolyzer is 5m * 3m * 5m, and 2 pairs of series electrode plates are installed in electrolyzer, and anode and cathode base material are all Titanium, the surface is plated with ruthenium and palladium respectively, and the area of each electrode plate is 20m 2 , each pair of electrode plate voltage 3.5V; electrolysis 30min. Analysis of Cl after electrolysis - Concentration, total number of heterotrophic bacteria and corrosion rate, the results are shown in Table 2. Add softener NaOH after electrolysis, and the dosage concentration is 200mg / L. Analytical Ca 2+ Concentration and corrosion rate, the results are shown in Table 2.

[0037] Table 2

[0038] project

Embodiment 3

[0040] Sewage from the first circulating water system of a chemical plant, Cl - And suspended matter content is high, and its composition before treatment is as shown in table 3, adopts the electrolysis of the inventive method to process. The size of the electrolytic cell is 10m×4m×4m, and 8 pairs of parallel electrode plates are installed in the electrolytic cell. The anode base material is titanium, the surface is plated with platinum, the cathode base material is titanium, and the surface is plated with iridium; the area of each electrode plate is 9m 2 , the voltage of each pair of electrode plates is 4.5V; electrolysis for 20min; analysis of Cl after electrolysis - Concentration, total number of heterotrophic bacteria and corrosion rate, the results are shown in Table 3. After electrolysis, carry out fiber filtration (the filter material is polyester long fiber, the silk diameter is 14-16μm, the porosity is 90%, and the specific surface area is 8000m 2 / m 3 , the heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com