Explosion protection system for a high pressure lamp

A high-pressure lamp and lamp cap technology, which is applied to the parts of gas discharge lamps, discharge lamps, discharge tubes, etc., can solve problems such as failure to effectively deal with reflector rupture, damage to the mechanical stress of the lamp, and inability to ensure protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, identical or functionally similar elements are identified with the same reference numerals.

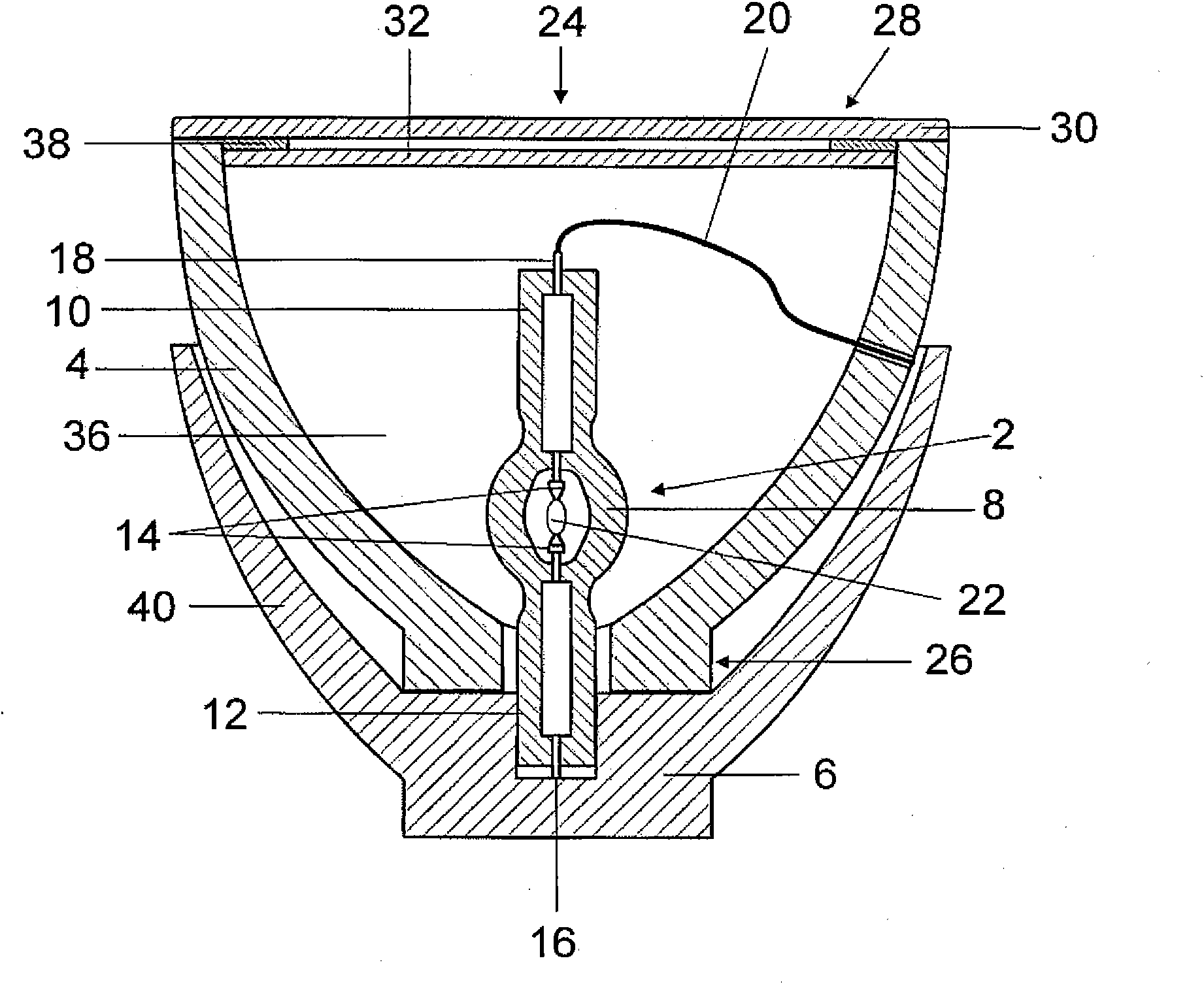

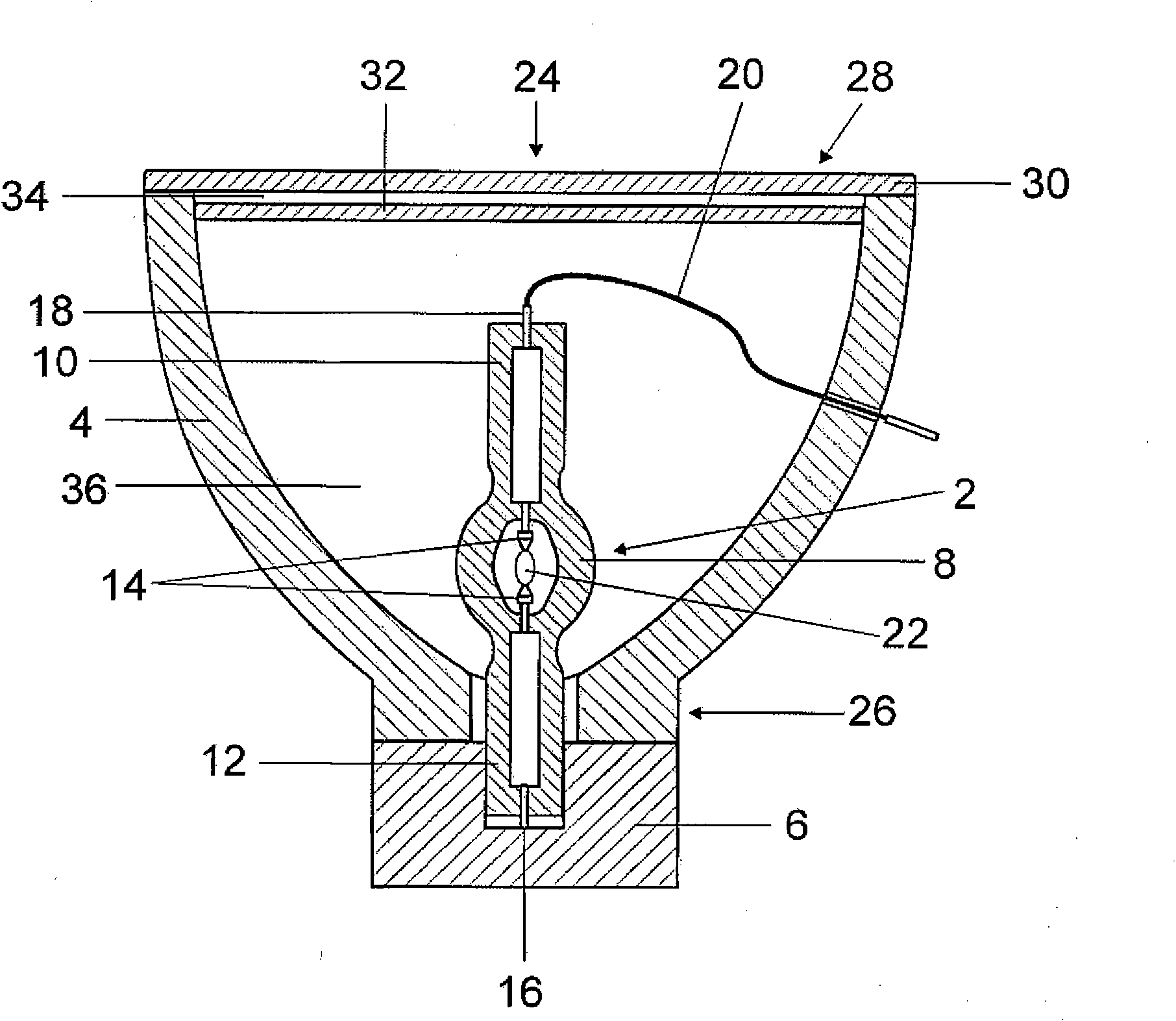

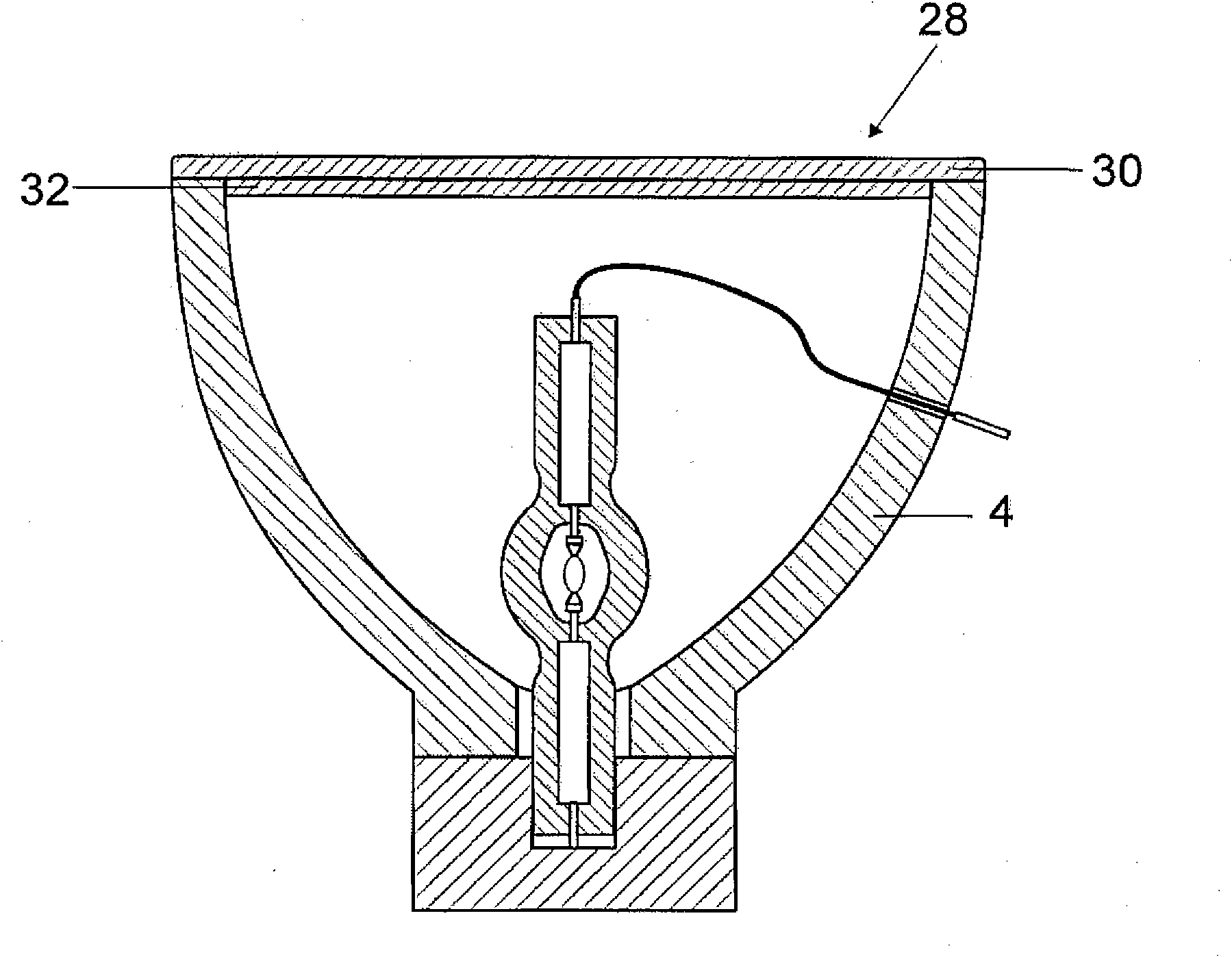

[0022] figure 1 A schematic diagram showing a first preferred embodiment of a lamp construction according to the invention. Such a lamp configuration has a discharge burner 2 which is surrounded by a reflector 4 and accommodated by a base 6 . The discharge burner itself has a discharge vessel or discharge bulb 8 filled with discharge gas, which is closed gas-tight by two sealing regions 10 and 12 , for example pinch regions. Embedded in the pinch regions 10 and 12 are electrodes 14 whose free ends project into the bulb 8 . In the pinch region 10 , 12 the electrodes are usually connected by a molten molybdenum film to the feed element 16 , 18 , wherein the feed element 16 is in electrical contact with the lamp cap 6 , while the feed element 18 is passed through the reflector 4 by a feed line 20 .

[0023] By applying a voltage between the electrodes 14 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com