Colored machinable glass-ceramics

A machining and glass technology, applied in the field of colored glass ceramics that can be machined, can solve the problem that the material is not machined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

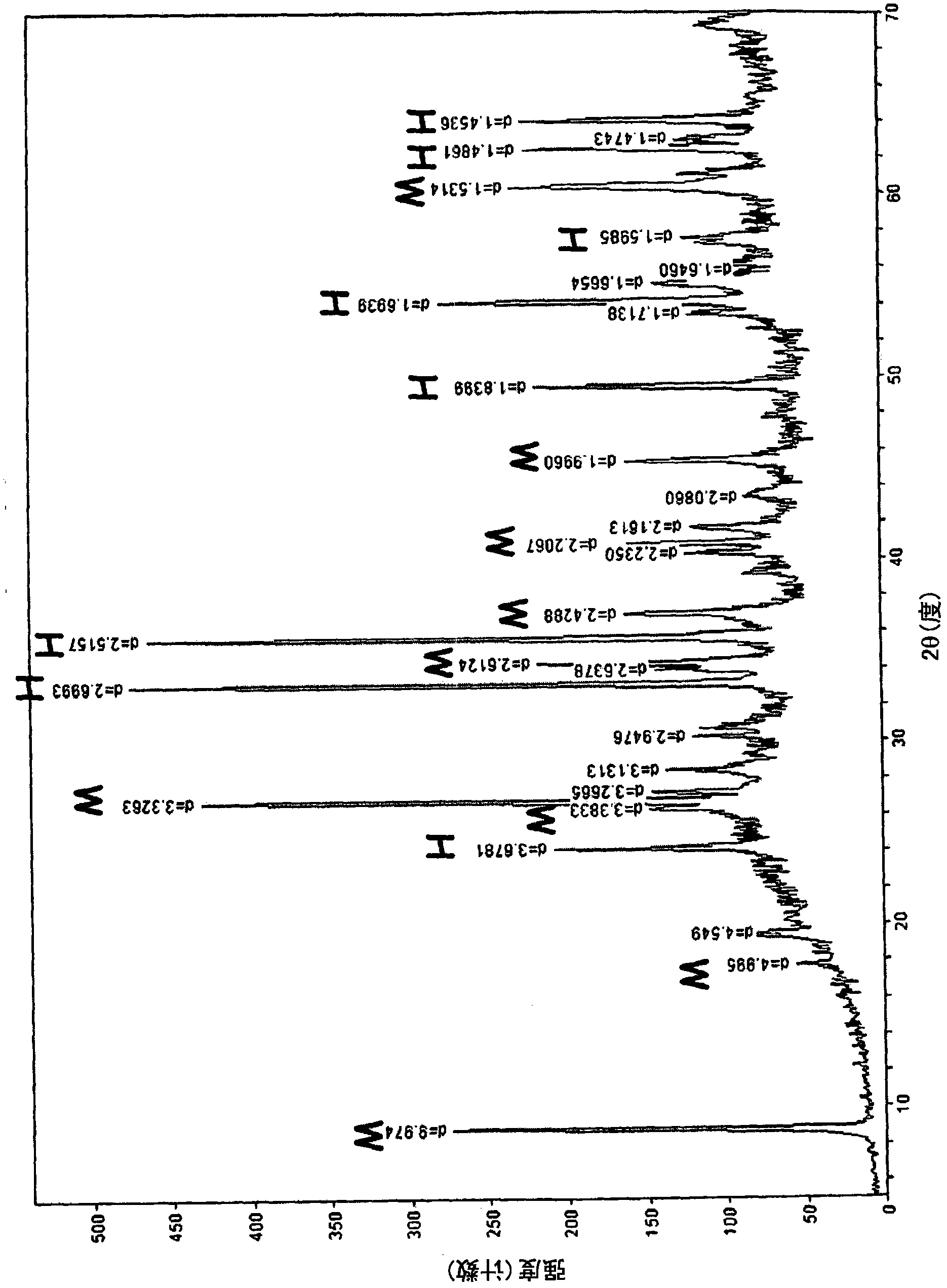

Image

Examples

Embodiment Construction

[0019] When the composition of the present invention is described in the range 0-X wt%, it means the amount of the material added to the batch excluding the contaminant content of the material. As is known to those of ordinary skill in the art, contaminant levels of metals, such as iron, can often be found in formulated glass and glass-ceramic products. Therefore, when describing a certain amount in the batch as 0-X% by weight in these cases, it is understood to mean "added material", when "added material = 0% by weight", it means the final glass - These materials present in ceramic materials are contaminant materials.

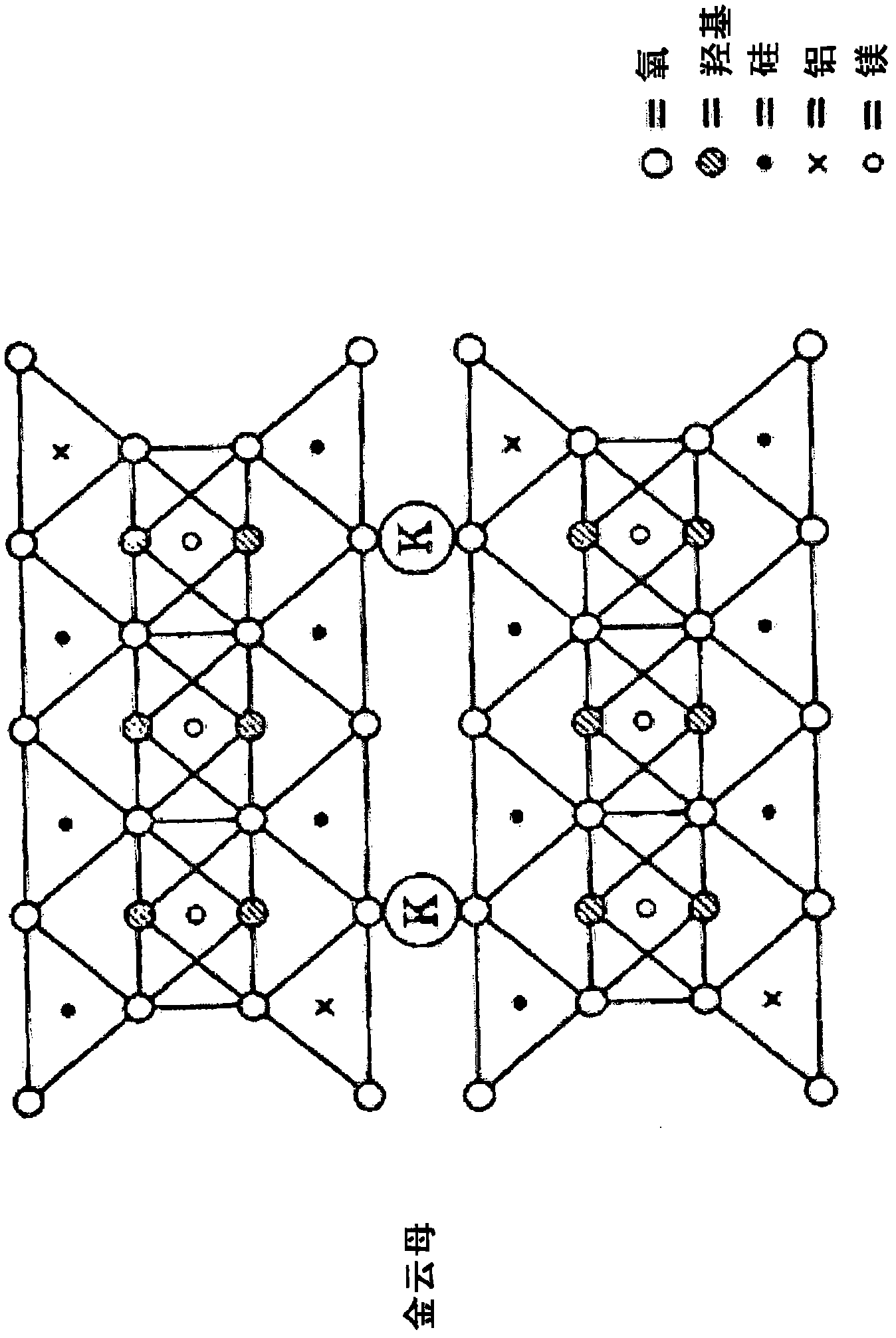

[0020] As introduced above, a large number of machinable glass-ceramic compositions have been described in the prior art, including those based on the trisilicon mica crystal structure (US 3,689,293), the tetrasilicon mica structure (US 3,732,087 and 3,839,055), and alkali-free Those compositions of metallic mica structures (US 3,756,838). Table 1 summarizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com