Air knocker with minimized impact

A vibrator and pneumatic technology, applied in the direction of portable impact tools, striking tools, pollution prevention methods, etc., can solve the problems of reducing magnetic piston recovery and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

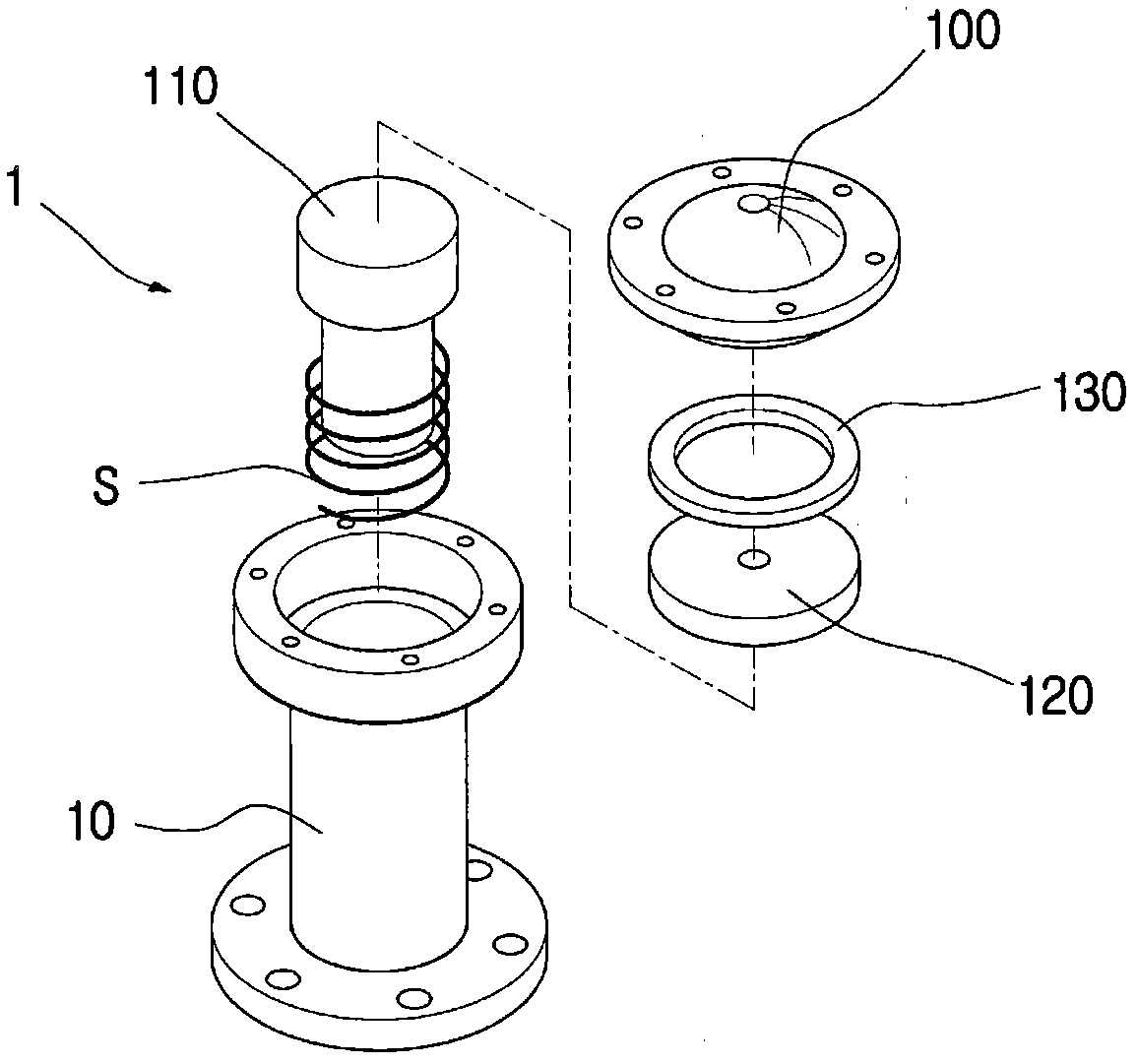

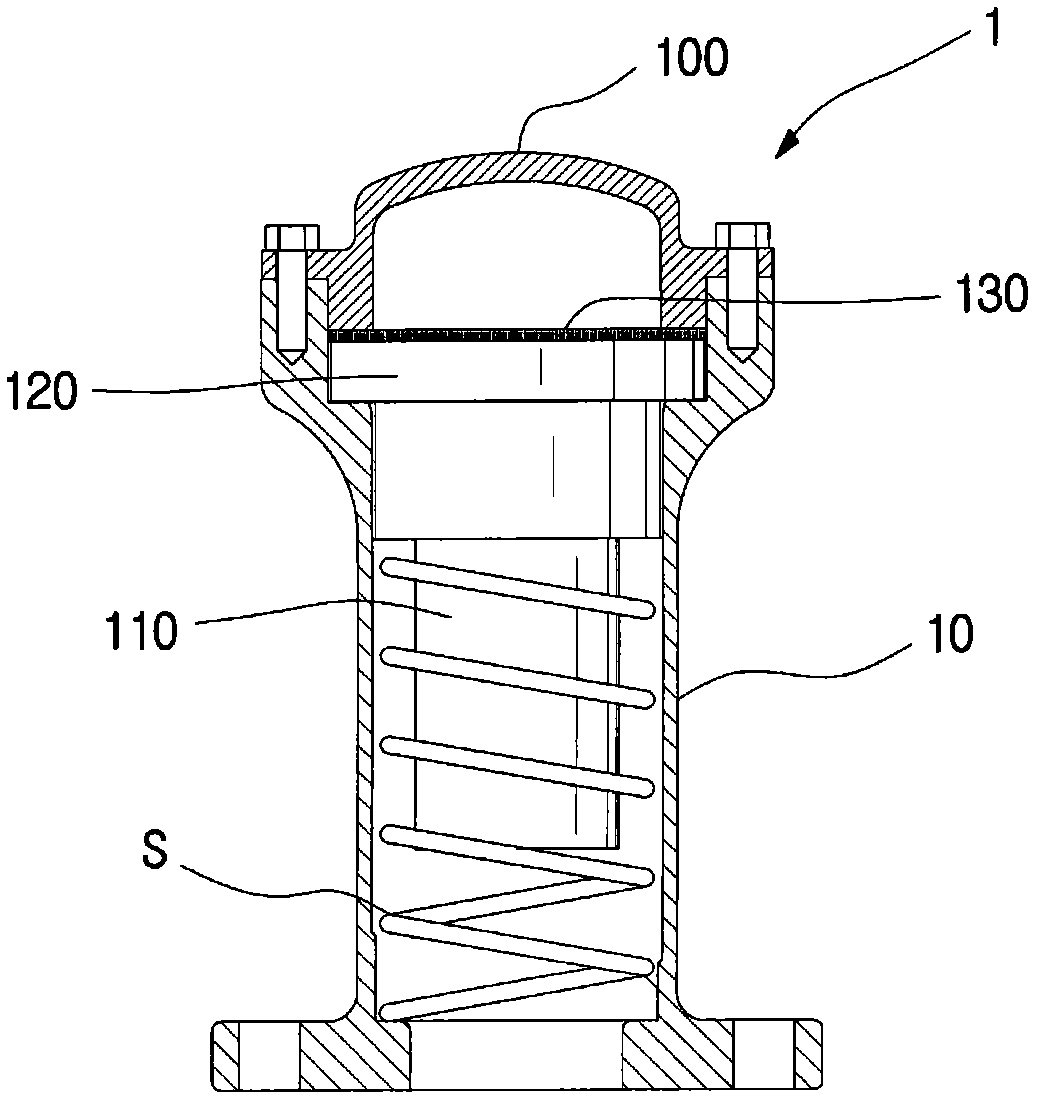

[0020] The pneumatic vibrator 1 of the present invention has a magnetic piston 110 under the elastic force of a spring S inside the cylinder 10, and a cylinder head 100 is connected to the upper part of the cylinder 10 by bolts, and the inside of the cylinder head 100 is equipped with a magnetic piston 110 for fixing. The fixed plate 120 of the magnetic piston 110 forms an insertion groove 111 at the end of the magnetic piston 110, and the insertion groove 111 is provided with a cushioning material 112 for absorbing the shock generated when the magnetic piston 110 strikes the powder tank 2. impact or noise.

[0021] The specific implementation of the present invention will be described in detail through the embodiments shown in the drawings.

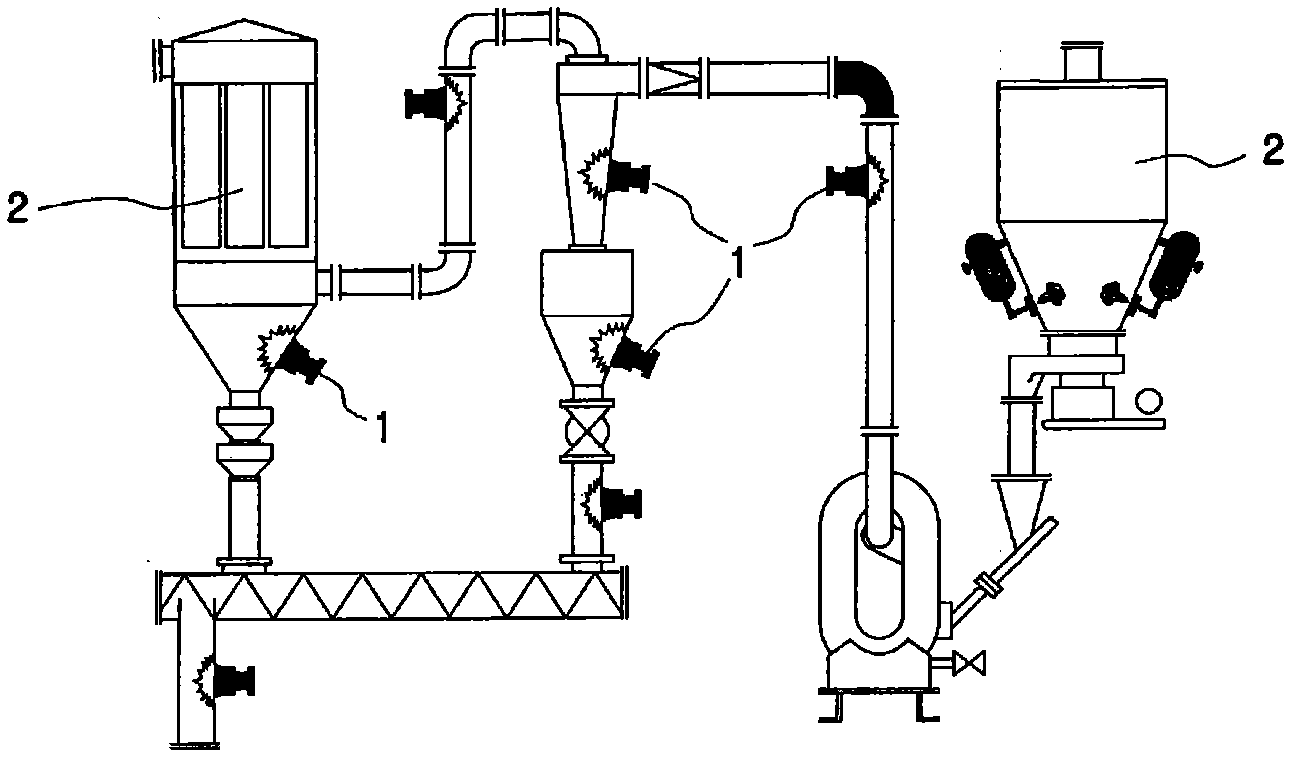

[0022] figure 1 is a schematic diagram showing a state of use of an embodiment of the present invention, figure 2 is an exploded perspective view showing the composition of an embodiment of the present invention, image 3 is a combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com