Method for measuring focus point of exposure machine

A focus point and exposure machine technology, which is applied to microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problems of too large focus point drift and too long measurement time of the exposure machine that cannot be found, and achieves short measurement time. The effect of high calculation accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

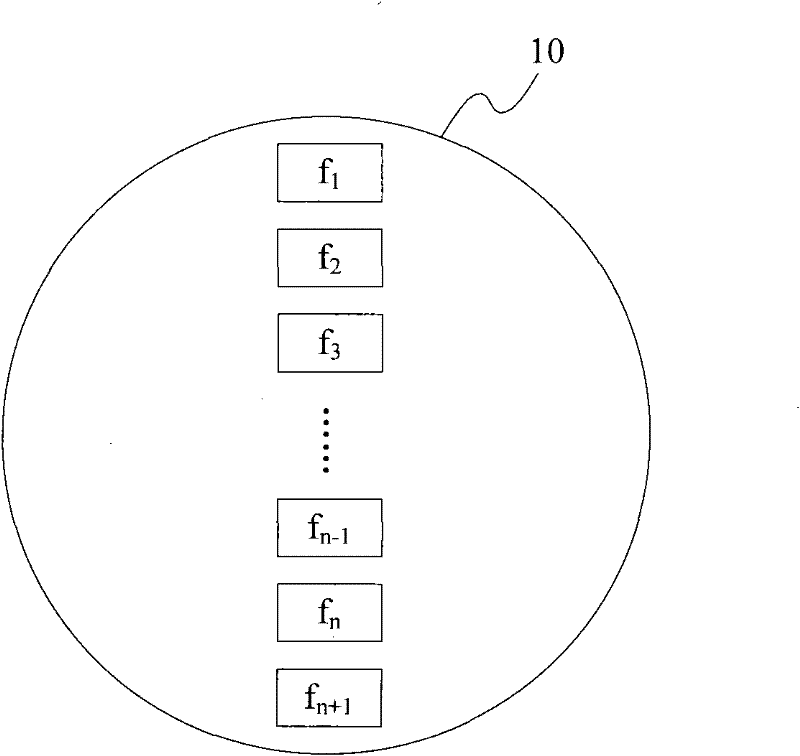

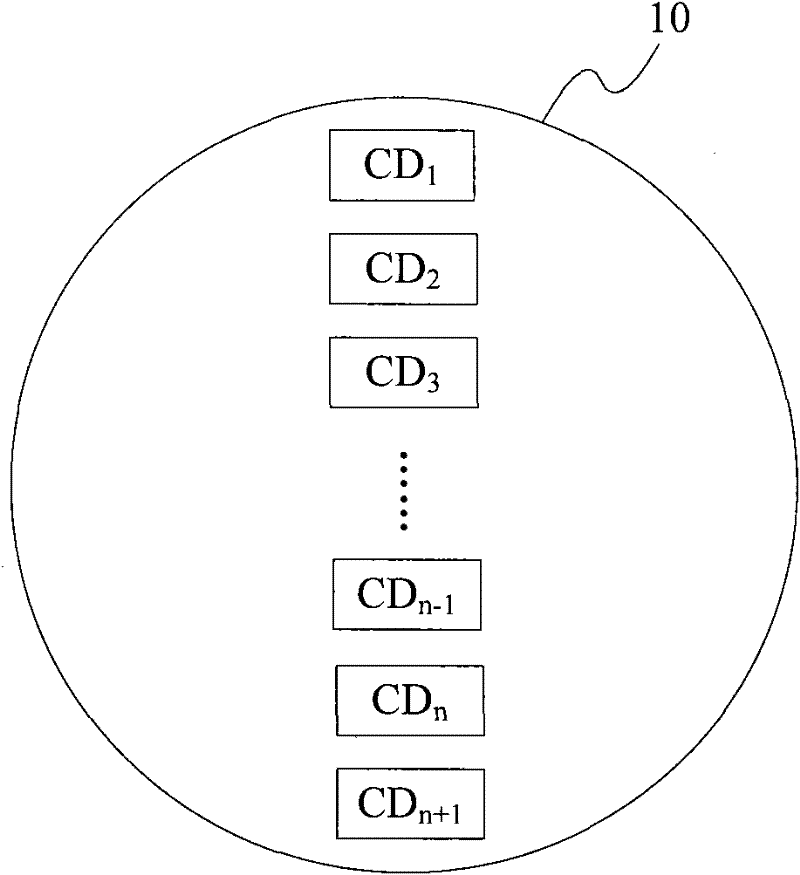

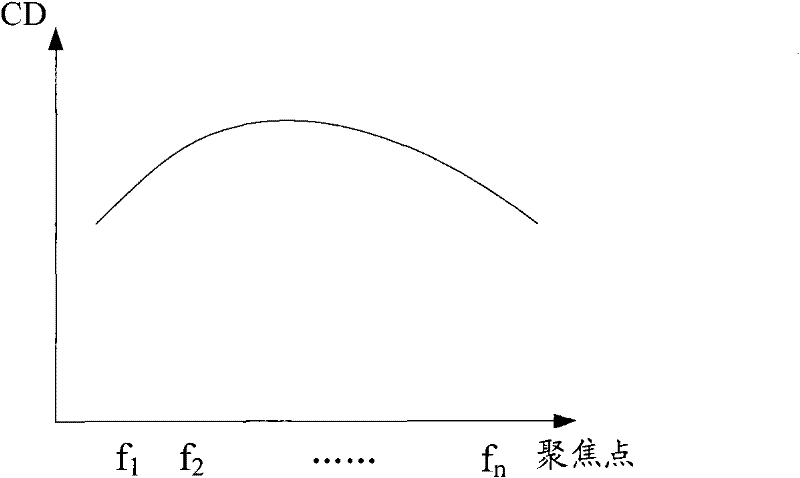

[0017] In the existing method of measuring the best focus point of the exposure machine, due to the large number of measurement points, the measurement time is too long and the measurement efficiency is reduced; in addition, the excessive drift of the focus point of the exposure machine cannot be found in time. The present invention establishes a database according to the relationship between measuring the overlay value of the overlay mark and the focal length; and can directly calculate the value of the focus point of the exposure machine in the manufacturing process of the semiconductor device according to the data therein and the overlay value between the patterns on the photoresist layer , the measurement time is short, and the efficiency is high; and the situation that the focus point of the exposure machine drifts too much can be found in time. In addition, a database is established by measuring the relationship between the overlay value of the overlay mark and the focal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com