Method for detecting hydrostatic pressure of thin-wall steel pipe under end face seal condition

A technology of thin-walled steel pipe and end face sealing, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

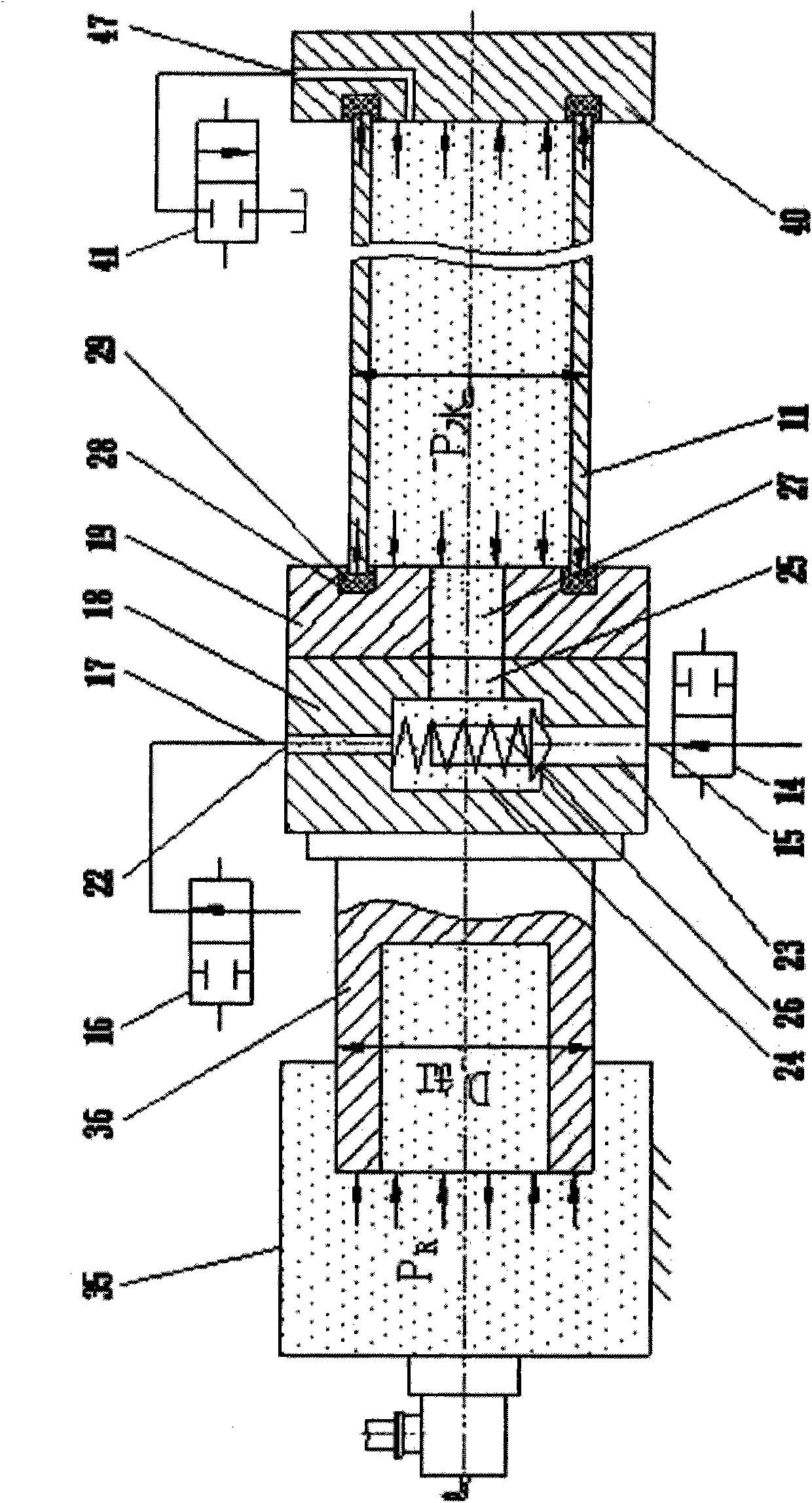

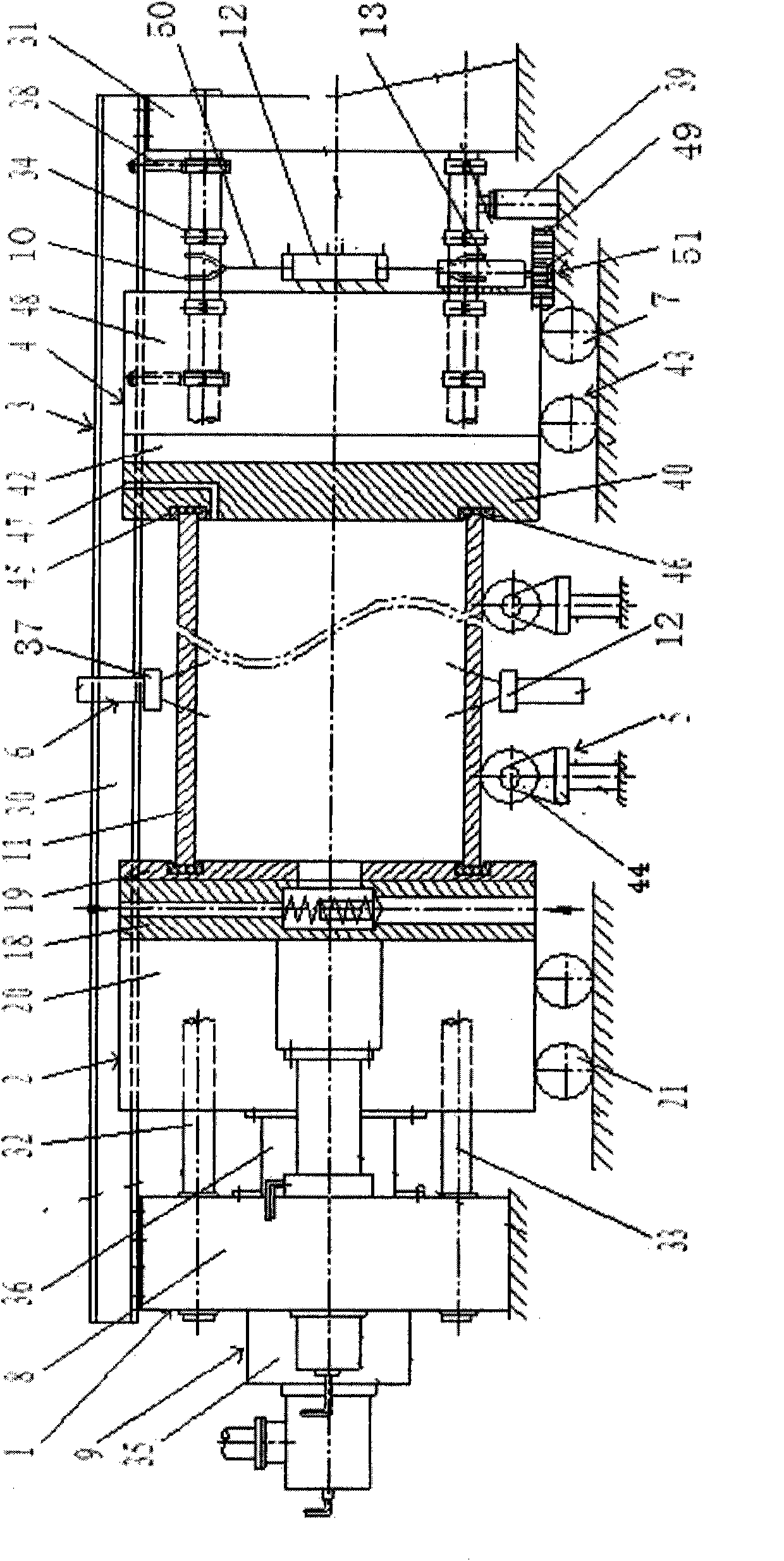

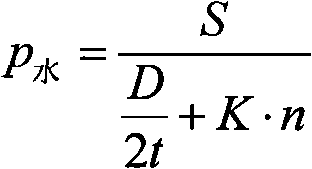

[0107] A method for testing hydrostatic pressure of thin-walled steel pipes with end face sealing, using a device that is a hydrostatic pressure testing machine for end face sealing steel pipes: including a testing machine body, a hydraulic system, a water pressure system and an electric control system.

[0108] The body of the testing machine includes the main body 1, the main test pressure head device 2, the first group of tension columns 32, the second group of tension columns 33, the rear fixed bracket device 3, the auxiliary test pressure head device 4, the idler device 5 and the clamping device 6 . The main body 1 and the auxiliary test head device 4 are connected through the two sets of tension columns 32 and 33 with the same structure.

[0109] The main body 1 is generally designed as a fixed type, which includes a front fixed bracket 8, a main hydraulic cylinder (also called an end face seal hydraulic cylinder) 9, two side hydraulic cylinders and a part of the facilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com