Dual clutch type variable transmission device with planetary gear train

A dual-clutch, planetary gear train technology, applied in gear transmissions, transmissions, belts/chains/gears, etc., can solve the problems of poor shifting smoothness, large radial size, and small number of gears. The effect of simplifying the control method and control link, reducing the radial and axial dimensions, and increasing the input and output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

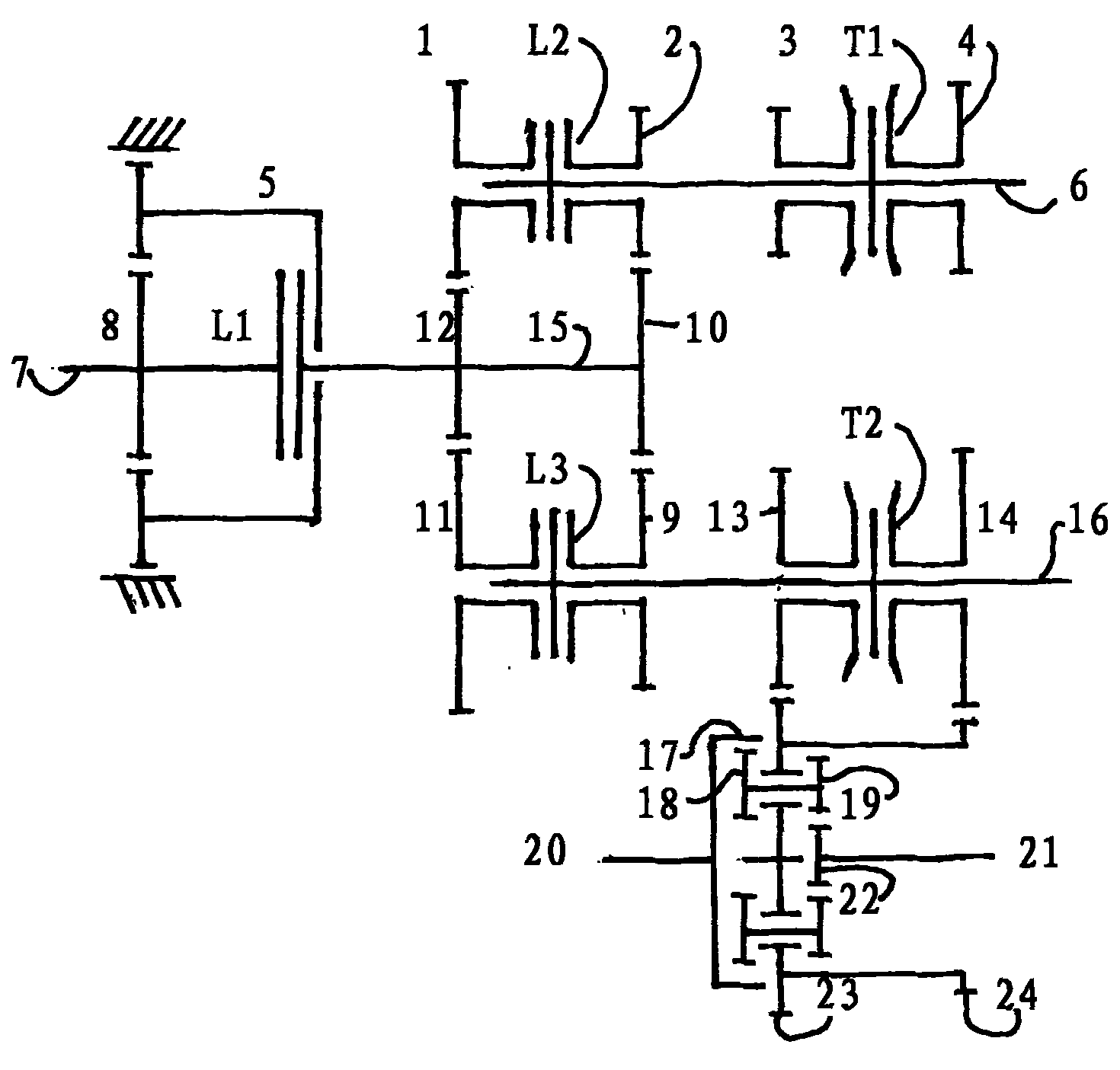

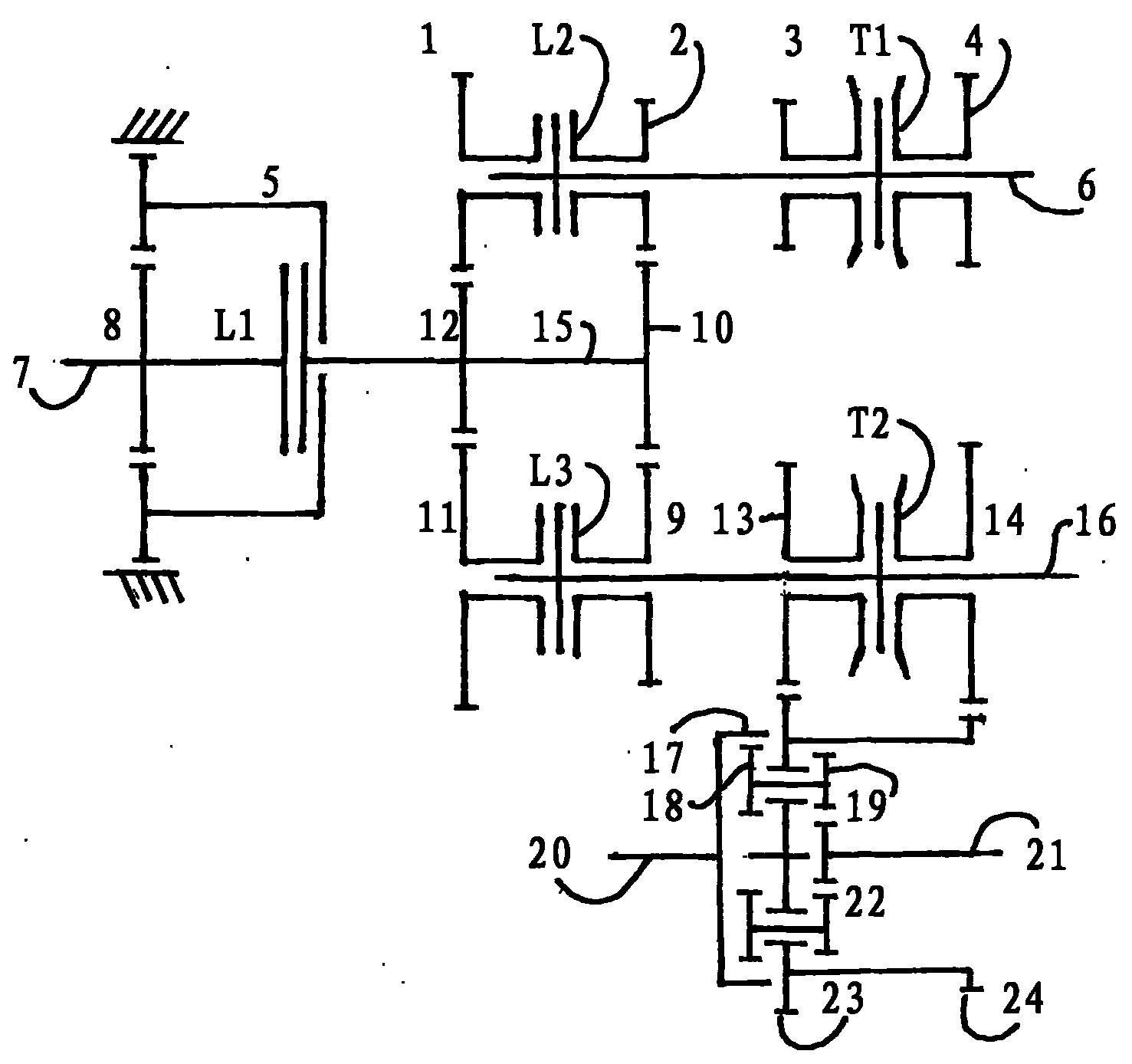

[0017] Such as figure 1 As shown, the sun gear shaft (7) is rigidly connected with the sun gear (8), and there is a double clutch (L1) between the sun gear shaft (7) and the planetary carrier (5) and the intermediate shaft (15). Two gears (12) (10) are connected, four gears (1) (2) (3) (4) that can rotate freely around its axis are arranged on the first auxiliary shaft (6), and the gears (1) (2) There is a double clutch (L2) between them, a synchronizer (TI) between the gears (3)(4), and there are four gears (11)(9) on the second countershaft (16) that can freely rotate around their axes (13)(14), there is a double clutch (L3) between the gears (11)(9), there is a synchronizer (T2) between the gears (13)(14), and the gears (1)(11) are respectively connected with the intermediate shaft (15) The upper gear (12) meshes, and the gear (2) meshes with the upper gear (10) of the intermediate shaft (15). Mesh with the gear (10) on the intermediate shaft (15) to produce a reverse gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com