Multi-parameter real-condition monitoring method for well completion of underground perforator

A perforator, multi-parameter technology, used in wellbore/well components, surveying, earthmoving, etc., to solve problems such as large volume, inconvenient operation, and inability to test adoption or implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1. Downhole perforator completion multi-parameter real-time monitoring method

[0035] The technical solution of the downhole perforator completion multi-parameter real-time monitoring method in this case first adopts the storage test technology. The pressure parameters, temperature parameters, especially the pressure parameters in the perforator and the acceleration data of the perforator itself are monitored at the same time. Secondly, the high temperature curing technology is adopted to solidify the circuit into a module, which improves the reliability of the circuit under high temperature, explosion and other shock conditions in the mine. The real-time monitoring method in this example is to use the monitoring instrument inside the perforator and the monitoring instrument outside the perforator to monitor and work together at the same time. After real-time processing of monitoring data and real-time storage of monitoring information, the perforation or comp...

Embodiment 2

[0036] Embodiment 2. Downhole perforator completion multi-parameter real-time monitoring method

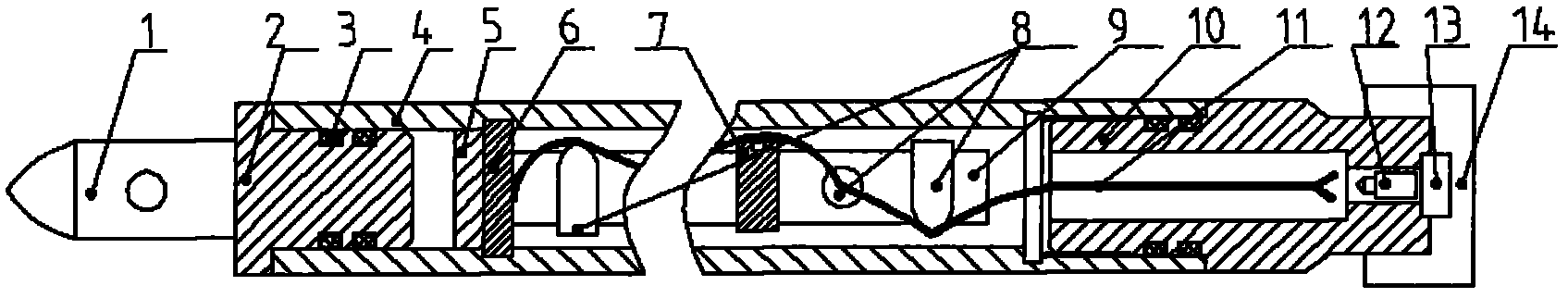

[0037] The specific structure of the perforator used in the downhole perforator completion multi-parameter live monitoring method in this example, the monitoring instrument inside the perforator, and the monitoring instrument outside the perforator are given by figure 1 , Figure 4 ~ Figure 16 etc. jointly show that, figure 1 It shows the general structure diagram of another perforator multi-parameter monitoring assembly adopted in the multi-parameter live monitoring method of downhole perforator completion. The difference between the multi-parameter live monitoring method of downhole perforator completion in this example and the multi-parameter live monitoring method of downhole perforator completion in Embodiment 1 is as follows: 1. A perforator interior is set in the middle of the perforator in this example The monitoring instrument 7, which is set or installed on the perfo...

Embodiment 3

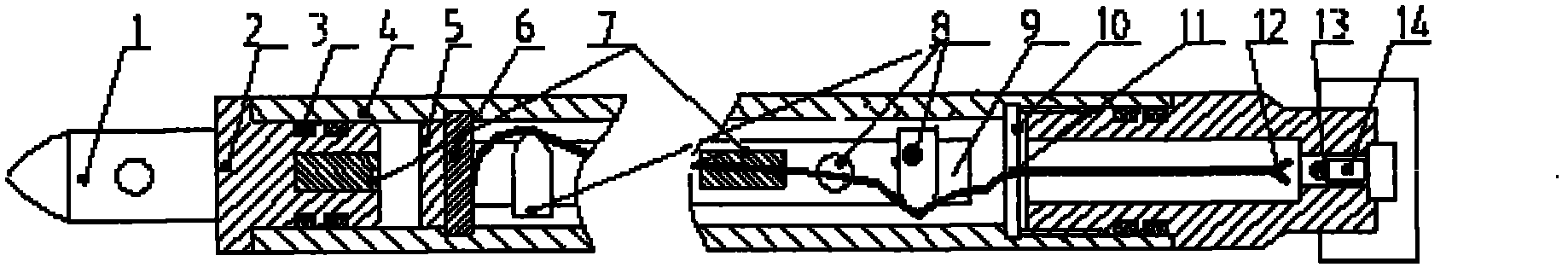

[0038] Example 3. Downhole perforator completion multi-parameter real-time monitoring method

[0039] The specific structure of the perforator used in the downhole perforator completion multi-parameter live monitoring method in this example, the monitoring instrument inside the perforator, and the monitoring instrument outside the perforator are given by figure 2 , Figure 4 ~ Figure 16 etc. jointly show that, figure 2 It shows the overall structure diagram of another perforator multi-parameter monitoring assembly adopted in the downhole perforator completion multi-parameter live monitoring method. The difference between the multi-parameter live monitoring method of downhole perforator completion in this example and the multi-parameter live monitoring method of downhole perforator completion in embodiment 1 and embodiment 2 is as follows: 1. The middle part of the perforator in this example is provided with a The monitoring instrument 7 in the perforator is set or placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com