Hydrotreating method for producing low-sulphur and ultra-low sulphur diesel oil

A technology of ultra-low sulfur diesel oil and hydrotreating, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of not taking into account, low space velocity, low diesel yield and so on, so as to avoid saturation of aromatic hydrocarbons , Improve the yield of diesel oil, reduce the effect of reaction hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

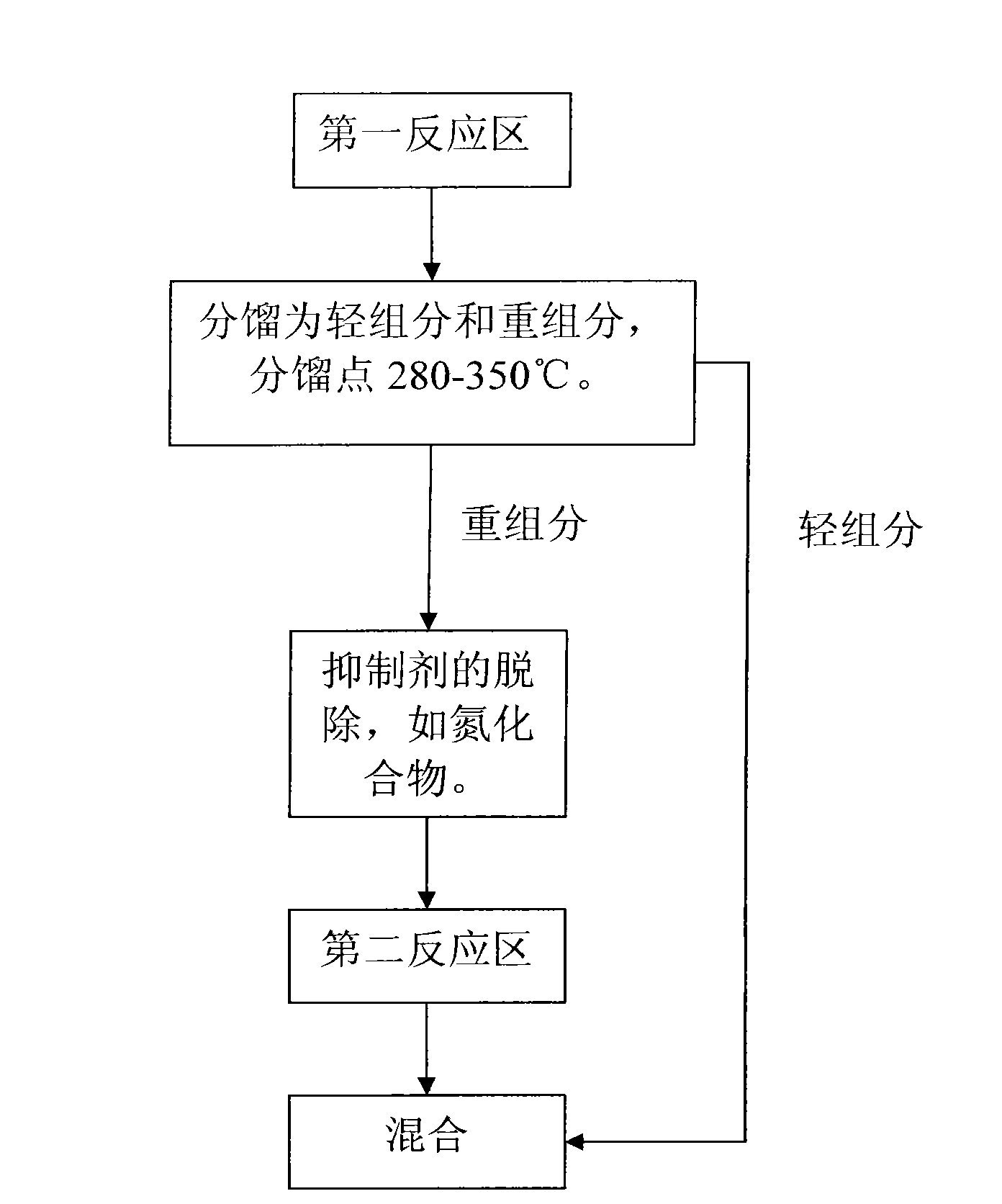

Method used

Image

Examples

Embodiment 1

[0031] The first reaction zone of this example adopts Mo-Co type hydrofinishing catalyst (FDS-4 hydrofinishing catalyst developed and produced by Fushun Petrochemical Research Institute), the direct hydrodesulfurization activity of this catalyst is relatively high, and the second reaction zone adopts W-Mo-Ni-Co hydrorefining catalyst (FH-UDS hydrorefining catalyst developed and produced by Fushun Petrochemical Research Institute), this catalyst has the characteristics of denitrogenation, aromatics saturation and deep hydrodesulfurization activity. The diesel oil after pre-hydrogenation in the first reaction zone is divided into 340°C heavy fraction, and the >340°C heavy fraction is sent to the second reaction zone after adsorption denitrogenation. Flow down mode of operation. The acidic cationic resin is used for adsorption and denitrification, the yield of diesel oil is 99.5%, and the removal rate of total nitrogen is 78%. See Table 3 for other process conditions and propert...

Embodiment 2

[0033] The first reaction zone of this example adopts Mo-Co type hydrofinishing catalyst (FDS-4 hydrofinishing catalyst developed and produced by Fushun Petrochemical Research Institute), the direct hydrodesulfurization activity of this catalyst is relatively high, and the second reaction zone adopts W-Mo-Ni type hydrorefining catalyst (FH-98 hydrorefining catalyst developed and produced by Fushun Petrochemical Research Institute), this catalyst has the characteristics of denitrogenation, aromatics saturation and deep hydrodesulfurization activity. The diesel oil after pre-hydrogenation in the first reaction zone is divided into light fraction 300°C, and the heavy fraction >300°C is sent to the second reaction zone after denitrification by adsorption, and the second reaction zone adopts gas-liquid countercurrent flow Operation method. Using dimethyl sulfoxide to extract and remove nitrogen, the yield of diesel oil is 98.7%, and the removal rate of total nitrogen is 67%. See T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com