Production process for polyethylene device condensing agent

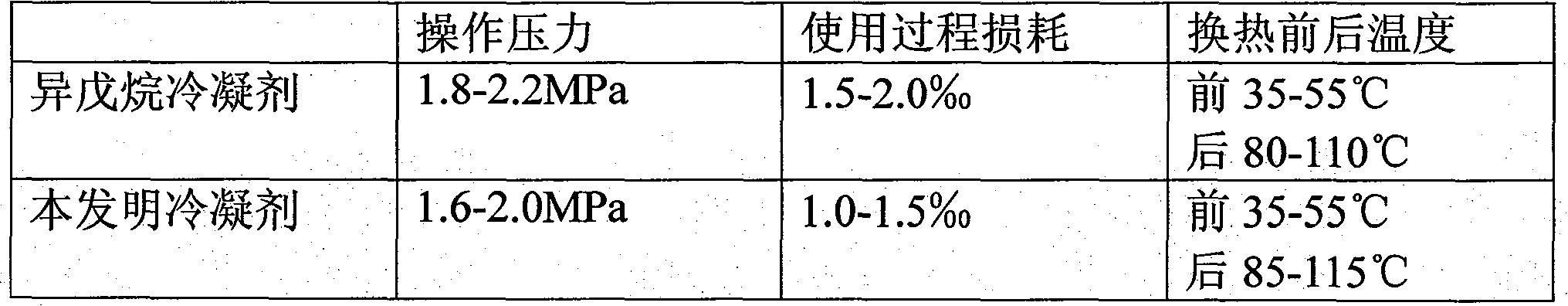

A production process and technology for condensing agents, which are applied in the petroleum industry, heat exchange materials, hydrocarbon distillation, etc., can solve the problems of n-pentane backlog, low production engineering yield, low isopentane content, etc., and achieve low operating costs. , Condensation effect is good, the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A production process of a condensing agent for a polyethylene plant, the production steps of which are sending naphtha (20°C, 0.8MPa) into a depentanizer, the operating pressure of the depentanizer is 0.55MPa, and the temperature at the top of the tower is 82°C , the temperature at the bottom of the tower is 162°C; the >nC5 component is separated from the bottom of the tower, and the ≤nC5 component is separated from the top of the tower and enters the debutanizer; the operating pressure of the debutanizer is 0.65MPa, and the top temperature is 58 ℃, the temperature at the bottom of the tower is 94°C; light components such as C3 and C4 are separated from the top of the tower, mixed pentane is separated from the bottom of the tower, and sent to the condensing agent generating tower for further separation; the operating pressure of the condensing agent generating tower is 0.3 MPa, the temperature at the top of the tower is 63°C, the temperature at the bottom of the tower is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com