Treating device and treating method for organic wastes in farm

A technology of organic waste and treatment equipment, which is applied in the direction of grain treatment, organic fertilizer, fertilization equipment, etc., can solve the problems of insufficient landfill, waste, secondary pollution, etc., and achieve accelerated granulation and feed efficiency, and accelerated treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

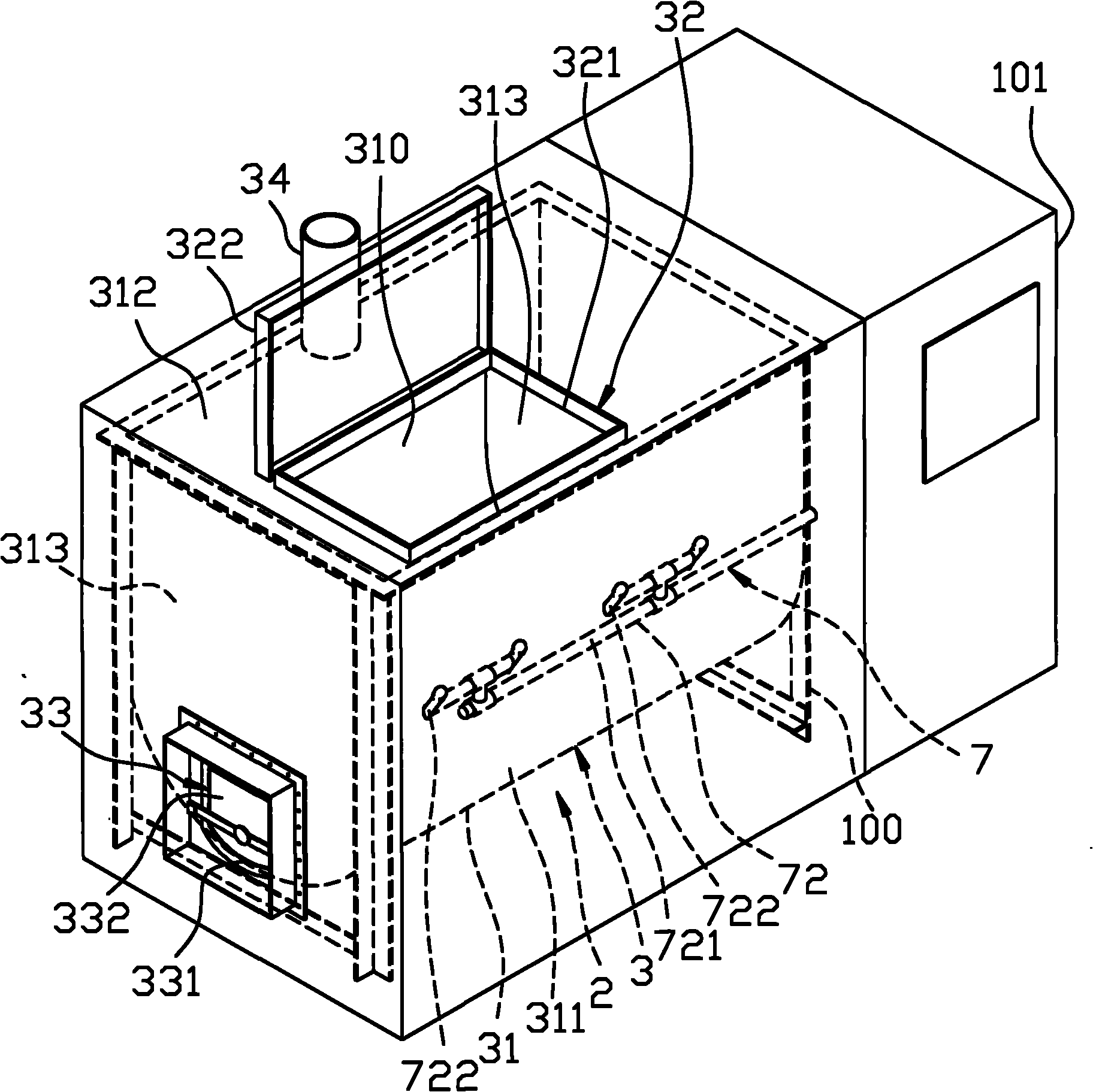

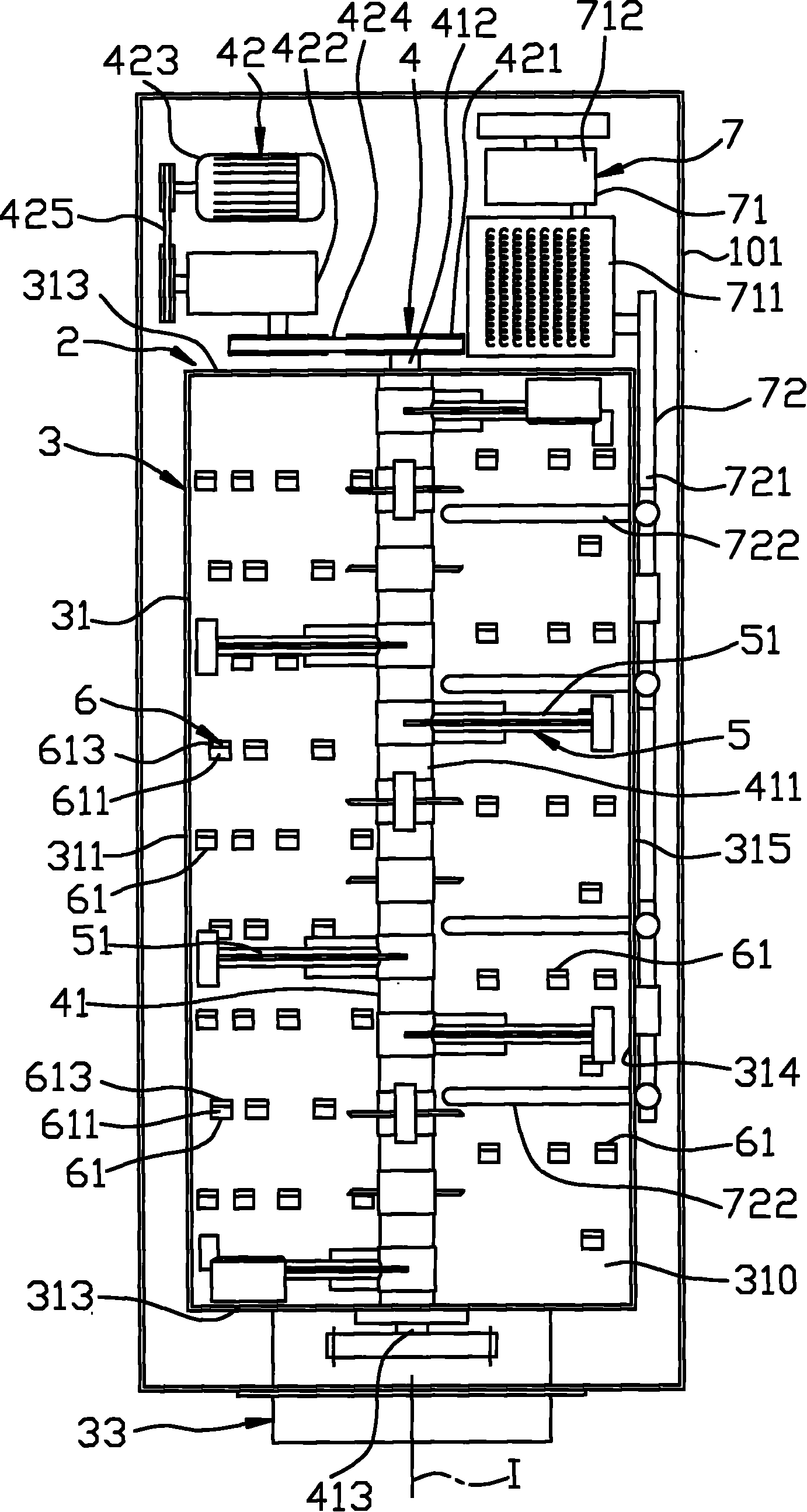

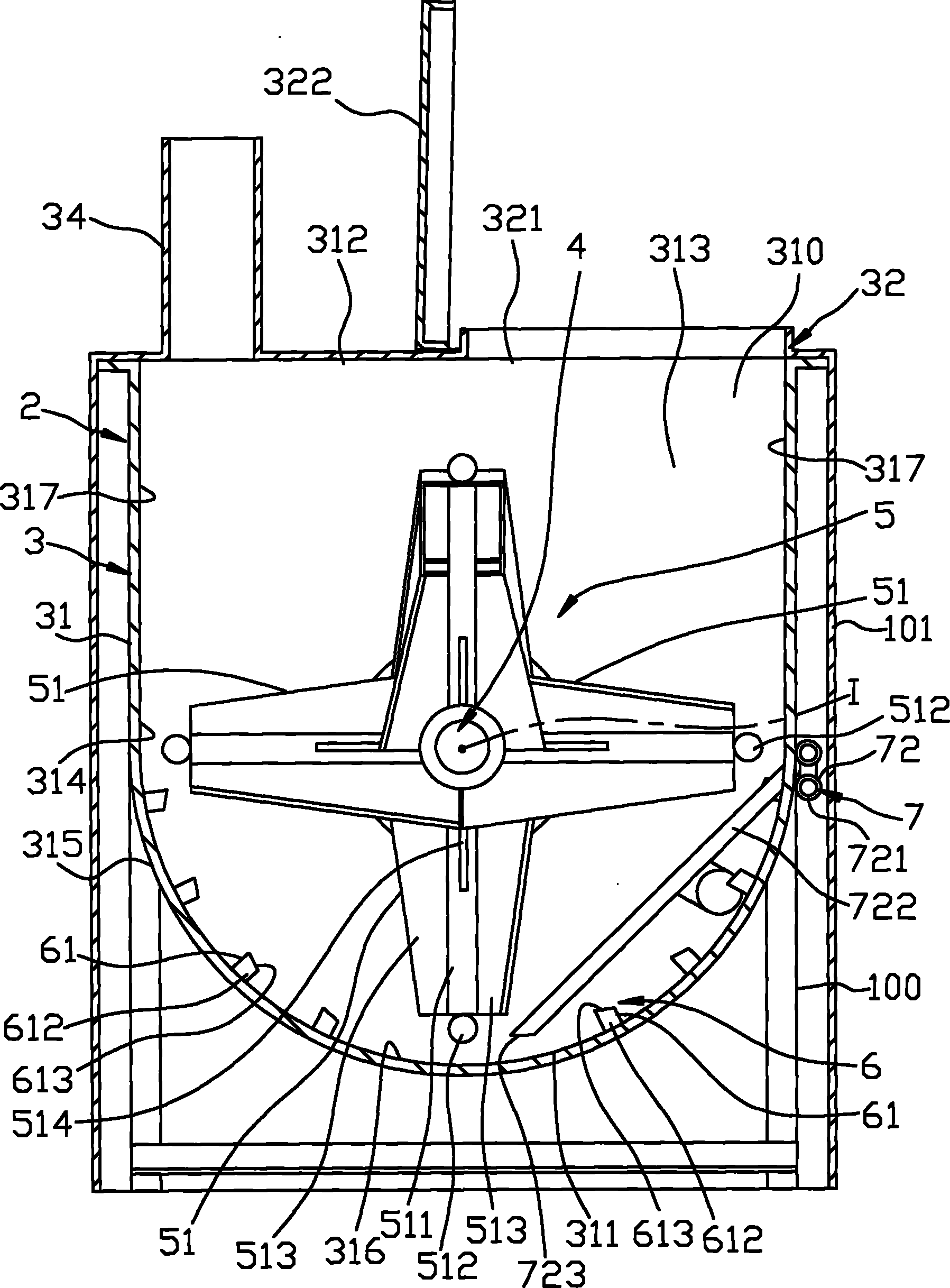

[0028] refer to figure 1 , figure 2 and image 3 , the preferred embodiment of the farm organic waste treatment device 2 of the present invention is installed on a frame 100 and surrounded by an outer casing 101. The organic waste treatment device 2 includes a treatment tank unit 3, a The rotating mechanism 4 of the processing tank unit 3, a first cutter unit 5 connected to the rotating mechanism 4, a second cutter unit 6 arranged in the processing tank unit 3, and a tool connected to the processing tank unit 3 Drying unit 7.

[0029] This treatment tank unit 3 comprises a main tank body 31, a feeding part 32, a discharge part 33 and a feeding part 33 spaced apart from the feeding part 32, 33 which are arranged on the main tank body 31 at intervals. Exhaust tube 34, the main tank body 31 has a base wall 311 with a U-shaped cross-section connected around an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com