Large sludge truck warehouse-out cleaning device

A cleaning device and sludge technology, applied in vehicle exterior cleaning devices, vehicle cleaning, vehicle cleaning equipment, etc., can solve problems such as difficult sludge truck cleaning, difficult chassis cleaning, and huge size, and reduce cleaning dead ends , reduce cleaning dead angle, maintain the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

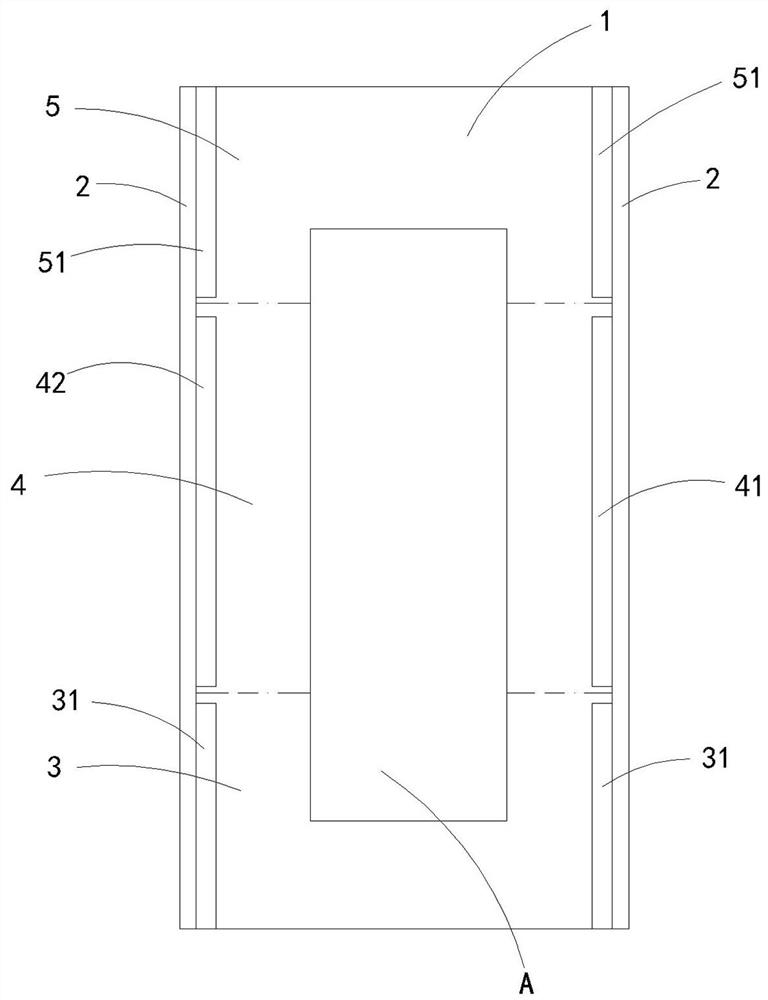

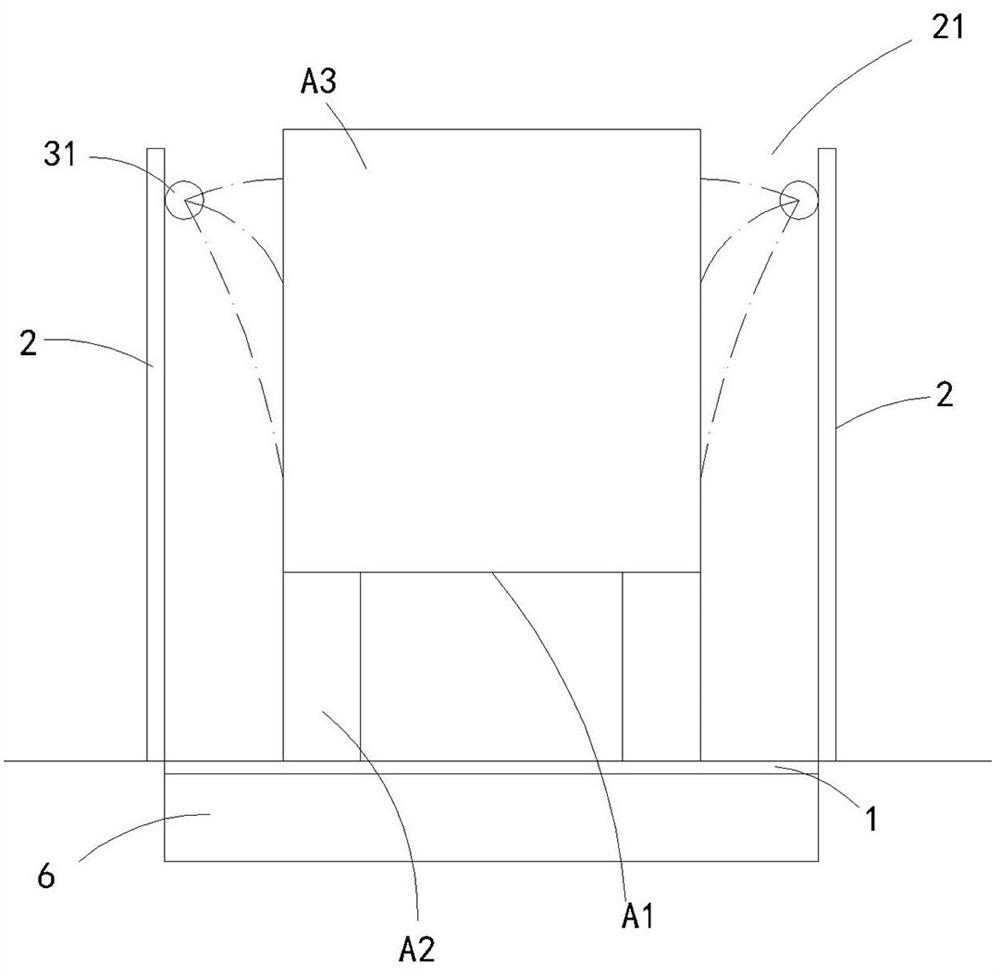

[0028] see Figure 1-5 , this embodiment provides a cleaning device for large-scale sludge trucks out of the warehouse, including a pit 6, a leaking plate 1 and a baffle plate 2.

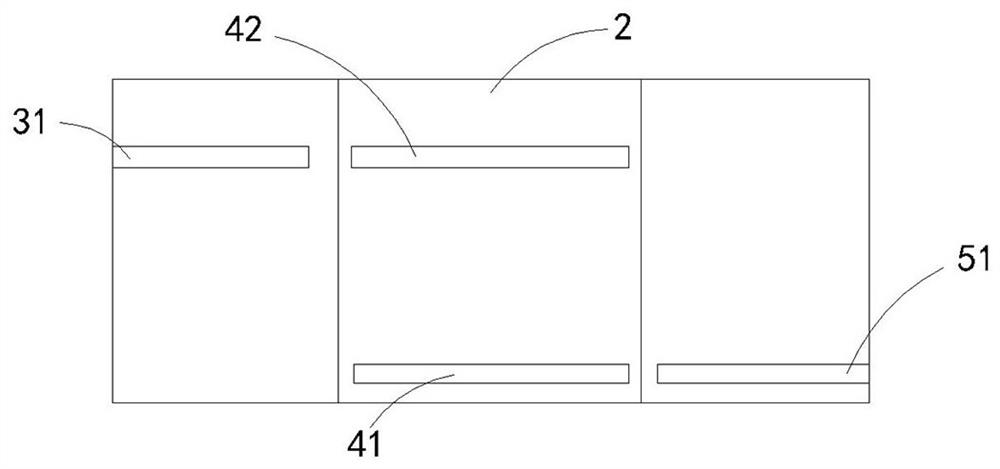

[0029] The leaking plate 1 is covered at the opening of the pit 6 for the sludge truck A to move above the pit 6 . There are two baffle plates 2 in number, and the two baffle plates 2 are arranged on the left and right side edges of the opening of the pit 6 respectively. Zone 5 and the buffer zone 4 are located between the cleaning zone 3 and the drying zone 5. The sludge truck A enters from the cleaning zone 3, passes through the cleaning zone 4, and then leaves from the drying zone 5. The structures of the two baffles 2 are symmetrical, so this embodiment uses the left baffle 2 as an example for illustration.

[0030] The baffle plate 2 is provided with a main water spray pipe 31 on the inner side of the cleaning area 3, the baffle plate 2 is provided with a secondary water spray pipe 41 and a s...

Embodiment 2

[0057] The difference between this embodiment and Embodiment 1 is that the secondary air pipe, the main water spray pipe, the main air pipe and the secondary water spray pipe cannot rotate on the baffle.

[0058] For some particularly huge sludge trucks, the height of the baffle may be insufficient, and the main spray pipe cannot clean the top of the outer wall of the compartment well, so the inner side of the baffle is movable along the vertical direction with a main rack And from the rack, the inner side of the baffle is also rotated with a transmission gear, the main water spray pipe is installed on the main rack, and the water spray pipe is installed on the slave rack. The transmission gear meshes with the main rack and the slave rack at the same time, so when the transmission gear rotates, it can drive the main spray pipe and the slave spray pipe to move in the vertical direction through the master rack and the slave rack respectively, so that the main The height of the s...

Embodiment 3

[0061] The difference between this embodiment and Embodiment 1 is that the baffle plate includes a lower plate and an upper plate slidably arranged on the lower plate, both the lower plate and the upper plate are vertically arranged, the bottom edge of the lower plate is located at the edge of the pit, and the upper plate The bottom edge is located in the middle of the lower plate, the main water spray pipe and the secondary air duct are located on the upper plate, and the secondary water spray pipe and the main air pipe are located on the lower plate. Therefore, the upper plate can synchronously drive the main water spray pipe and the secondary air pipe to move up and down, so as to match the height of the sludge truck, not only can the main water spray pipe shoot directly at the top of the car, but also adjust the height of the baffle, thereby increasing The shielding range of the baffle is improved, and the water flow formed in the middle of the channel is effectively reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com