Regeneration material of dermis substitution for tissue engineering skin for loading rhGM-CSF and preparation method thereof

A tissue-engineered skin and substitute technology, applied in the field of artificial dermis substitute regeneration material and its preparation, can solve the problems of easy degradation, unstable cytokine activity, etc., to accelerate the process of vascularization, reduce the risk of infection, and reduce scarring. proliferative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

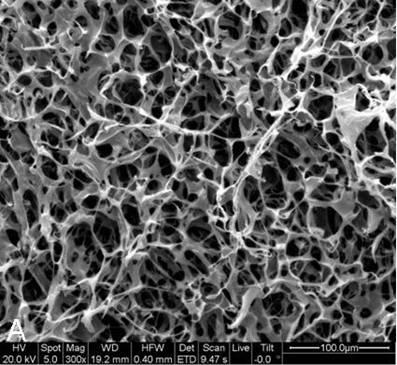

[0036] Collagen and chitosan were made into 0.5% acetic acid solution with a mass fraction of 0.5%, and then the collagen solution and chitosan solution were mixed according to the volume ratio of 9:1, fully stirred evenly, and injected into a mold with a diameter of 2 cm to make it After the height reaches 1.5mm, place it at 4°C for 24 hours, freeze it at -20°C for 24 hours, and then place it in a lyophilizer for 16 hours; freeze-dried scaffolds are cross-linked under vacuum at 105°C for 24 hours; Heparin was added to 0.05M MES (pH5.4) of EDC (20mmmol) and N-hydroxysuccinimide (NHS) at a molar ratio of 2:1 based on a heparin-to-collagen mass ratio of 1:10 solution, and then place the lyophilized scaffold in the mixed solution for cross-linking for 24 hours, and then freeze-lyophilize again after repeated washing to obtain a cross-linked heparinized collagen-chitosan scaffold (for microstructure, see figure 1 ).

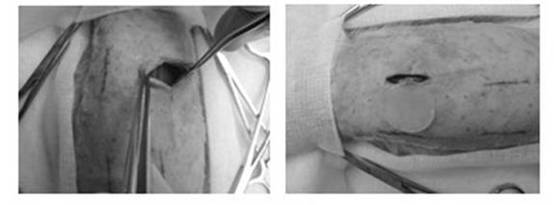

[0037] After the heparinized collagen-chitosan scaffold was st...

Embodiment 3

[0039] Collagen and chitosan were made into 0.5% acetic acid solution with a mass fraction of 0.5%, and then the collagen solution and chitosan solution were mixed according to the volume ratio of 9:1, fully stirred evenly, and injected into a mold with a diameter of 2 cm to make it When the height reaches 1.5mm, place it at 4°C for 24 hours, freeze it at -20°C for 24 hours, and then place it in a lyophilizer for 16 hours; freeze-dried scaffolds are cross-linked under vacuum at 105°C for 24 hours; Heparin was added to 0.05M MES (pH5.4) of EDC (20mmmol) and N-hydroxysuccinimide (NHS) at a molar ratio of 2:1 based on a heparin-to-collagen mass ratio of 1:10 solution, and then place the lyophilized scaffold in the mixed solution for cross-linking for 24 hours, and then freeze-lyophilize again after repeated washing to obtain a cross-linked heparinized collagen-chitosan scaffold (for microstructure, see figure 1 ).

[0040] After the heparinized collagen-chitosan scaffold was ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com