Circuit repair paster structure and manufacturing method thereof as well as circuit board and repair method thereof

A circuit board and patch technology, which is applied in the circuit repair patch structure and its production, circuit board and repair fields, can solve problems such as pad falling off, line breaking, circuit board scrapping, etc., to ensure orderliness and aesthetics, The effect of avoiding scrap and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

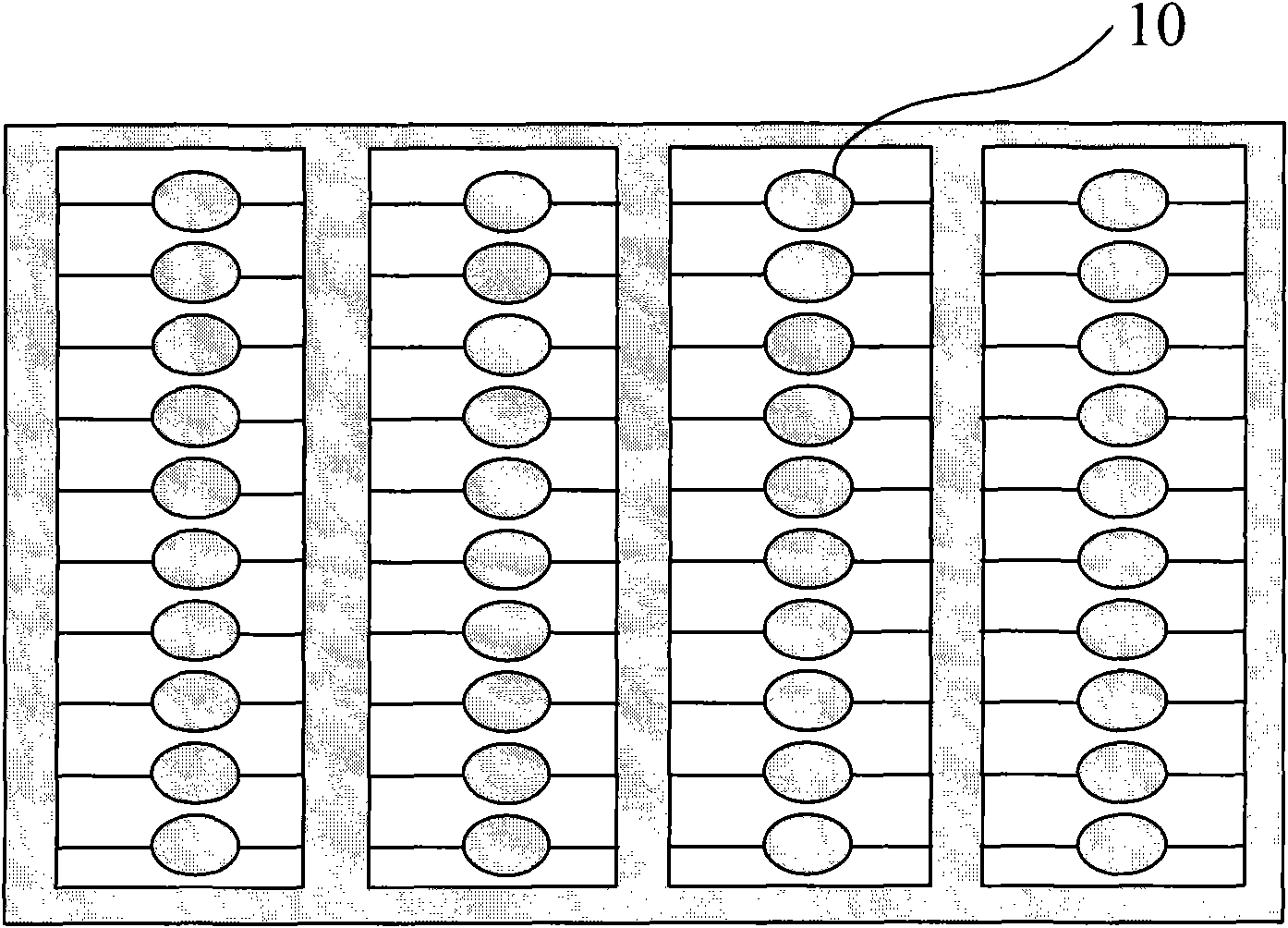

[0028] The circuit repair patch structure provided in this embodiment is a circuit repair patch group, including a plurality of circuit repair patches, such as figure 1 As shown, this embodiment is a rectangular metal frame, and a plurality of circuit repair patches 10 are arranged in the inner frame. And a plurality of circuit repair patches 10 of a single size. That is to say, the repaired circuit pattern in this embodiment is single, and when pads of the same or similar shape and size fall off on the circuit board, the circuit repair patch 10 in this embodiment can be used for repair.

[0029] Of course, in the circuit repair patch structure of this embodiment, the size and shape of the circuit repair patch 10 are not limited, and can be any shape and size.

[0030] The circuit repair patch structure provided in this embodiment can provide multiple circuit repair patches, that is, can provide circuit repair patches in batches for processes such as circuit board assembly, a...

Embodiment 2

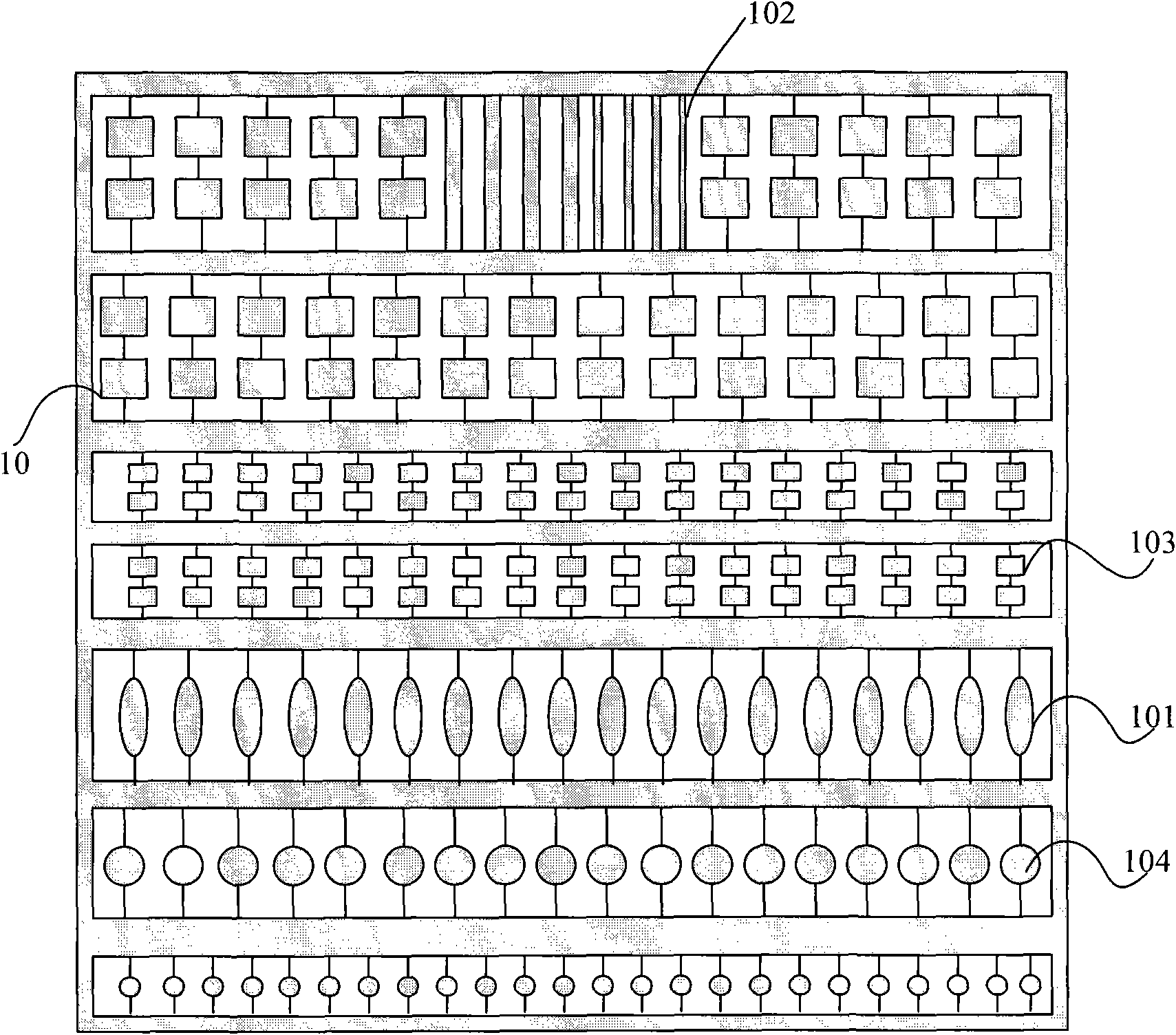

[0032] The circuit repair patch structure provided in this embodiment is also a circuit repair patch group, including a plurality of circuit repair patches, such as figure 2 As shown, it is the same as Embodiment 1. This embodiment is a rectangular metal frame, and a plurality of circuit repair patches 10 are arranged in the inner frame. The difference from Embodiment 1 is that this embodiment includes circuit repair patches 10 of various shapes. Patch 10 includes oval pad-shaped patch 101, line-shaped patch 102, square pad-shaped patch 103 and circular pad 104, etc., and each shape of circuit repair patch 10 includes at least one size. That is, the circuit patterns for repairing in this embodiment are diverse. When there is a break or shedding phenomenon on the circuit board, the corresponding circuit repair patch 10 of the same or similar shape and size can be used in this embodiment. The circuit pattern of the damaged part Make tinkering.

[0033] Of course, in the circu...

Embodiment 3

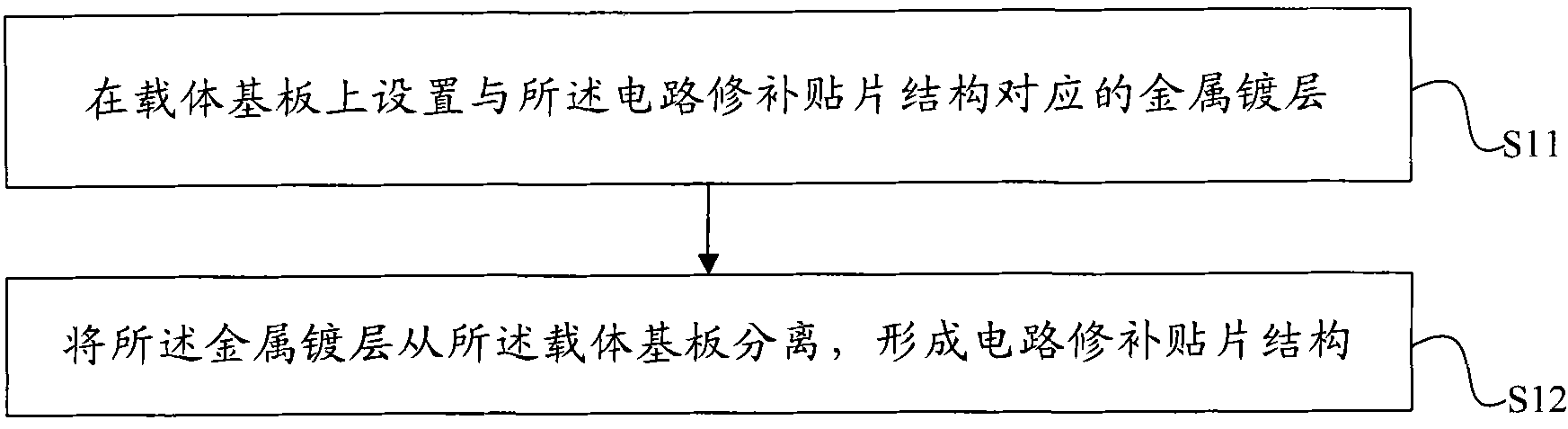

[0044] This embodiment can be called addition method, such as Figure 4 shown, including:

[0045] S21, using a steel plate as a carrier substrate, and chemically cleaning the steel plate;

[0046] This step is mainly to remove impurities and dirt on the surface of the steel plate, and to make the surface of the steel plate smooth and flat.

[0047] Certainly, carrier substrates of other materials may also be used in this step.

[0048] S22, pasting a dry film on the surface of the steel plate;

[0049] S23, transferring the pattern of the prepared circuit repair patch structure to the surface of the steel plate by exposure and development;

[0050] After this step, the part of the surface of the steel plate corresponding to the circuit repair patch structure will be exposed, and the other parts will be covered with a dry film. According to actual requirements, the pattern of the circuit repair patch structure can be set, and the pattern of the circuit repair patch structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com