Solar charging control circuit

A charging control and solar cell technology, applied in the field of electric power, can solve the problems of different charging current, easily damaged batteries, and different recovery of battery capacity, achieve high-precision temperature compensation function, improve energy conversion efficiency, and accurate charging control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in conjunction with the following examples.

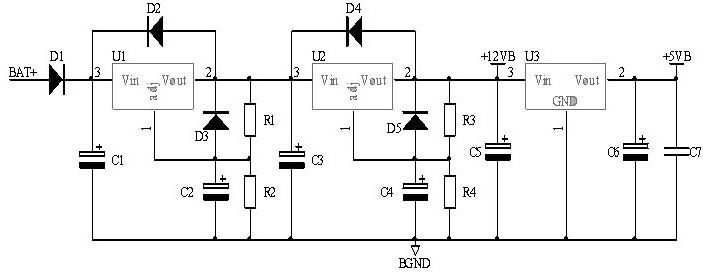

[0036] Solar charging control circuit of the present invention such as figure 1 As shown, it is used to control the solar battery to charge the battery and supply power to the load, including power conversion circuit, sampling circuit, microcontroller, PWM power drive circuit and output protection and power drive circuit, charging circuit and load circuit, and protection circuit, Man-machine interface circuit, LED and LCD display module and other modules.

[0037] The charging controller adopts a common positive circuit topology, the positive pole of the solar cell, the positive pole of the storage battery and the positive pole of the load are connected together; a transient voltage suppression diode TVS with lightning protection function is connected between the positive pole and the negative pole of the solar battery; The negative electrode is connected to the logic common g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com