Novel heat exchanger adopting corrugated tube as heat exchange tube

A technology of heat exchange tubes and heat exchangers, which is applied in the direction of heat exchanger types, indirect heat exchangers, fixed tubular conduit components, etc., can solve the problem of small heat exchange area, low heat exchange efficiency, and heavy heat exchanger weight problems, to achieve the effect of large heat exchange area, low production cost and total weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

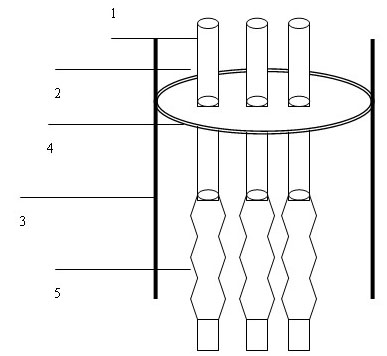

[0010] exist figure 1 Among them, several corrugated pipes (1) pass through the heat exchanger shell (3) and are fixed in the shell by each support plate (4). The cylindrical section of the bellows is connected to the support plates, while the corrugated section (5) is located between the support plates. One medium enters the heat exchange tubes, and the other medium flows in the space between the shell and the heat exchange tubes. The two media pass through the bellows for heat exchange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com