Novel movable support type heavy-duty drag chain

A support type, new technology, applied in the direction of drag chain, hanging chain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

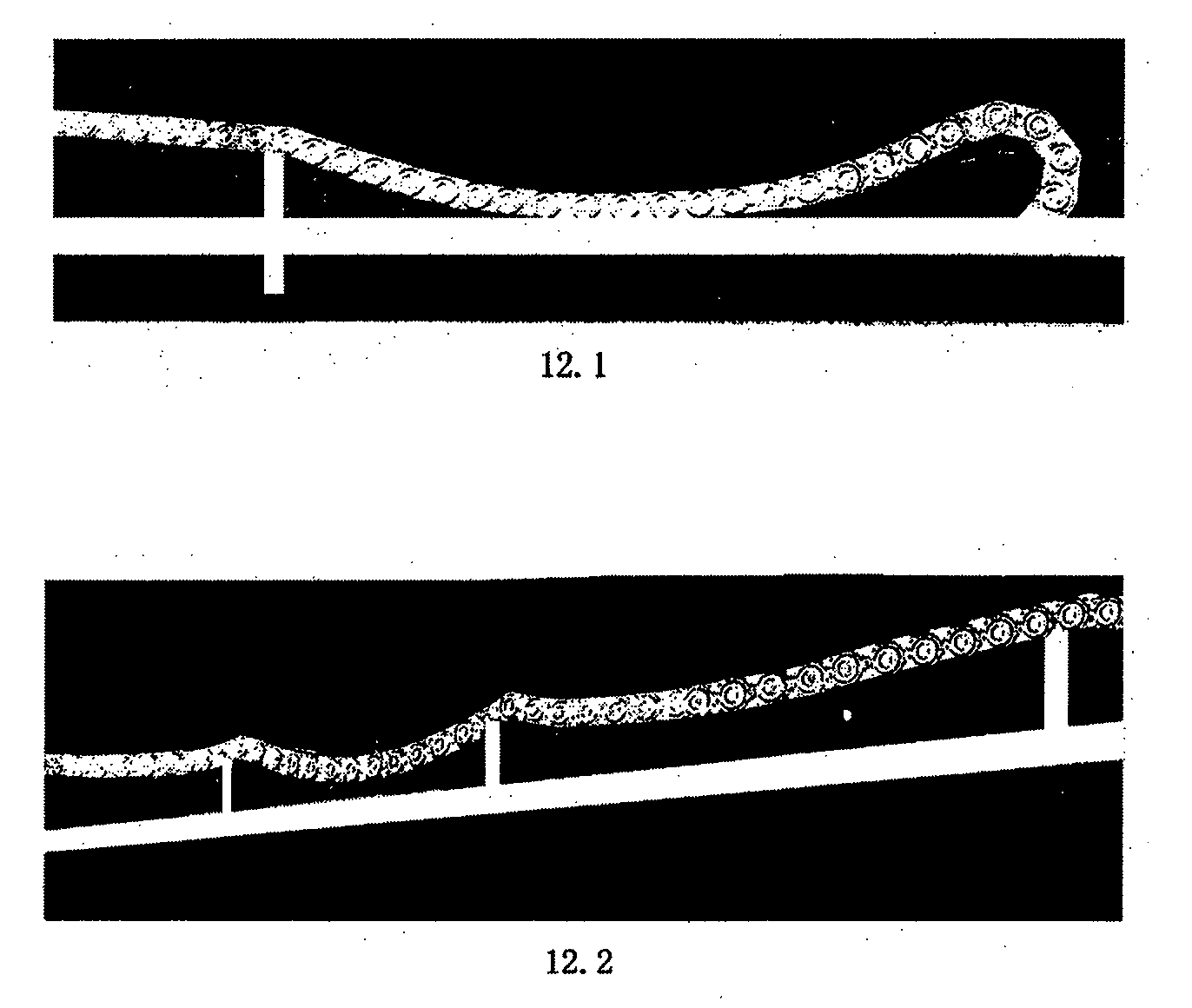

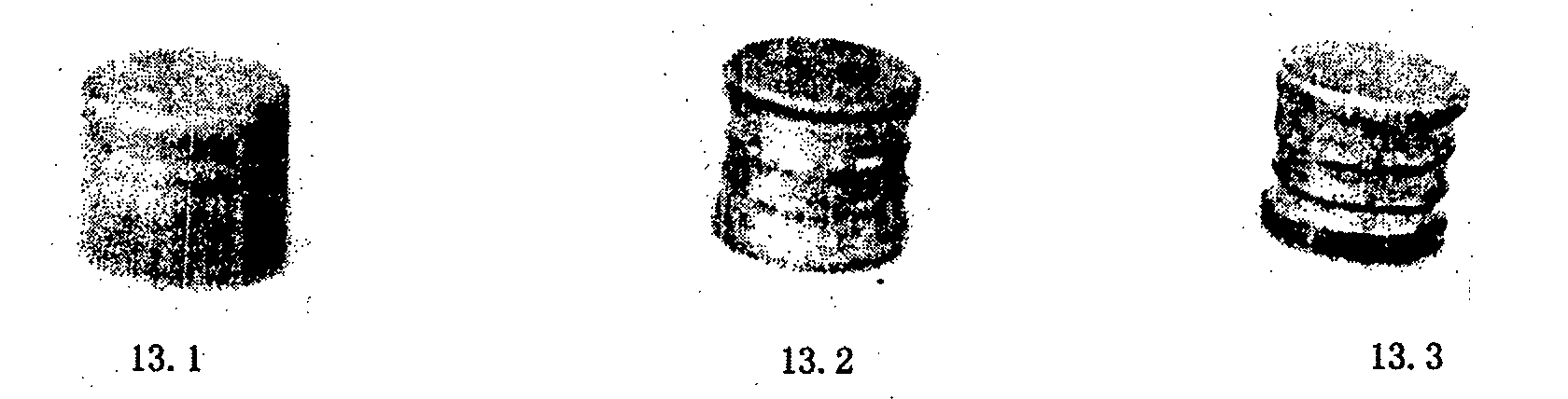

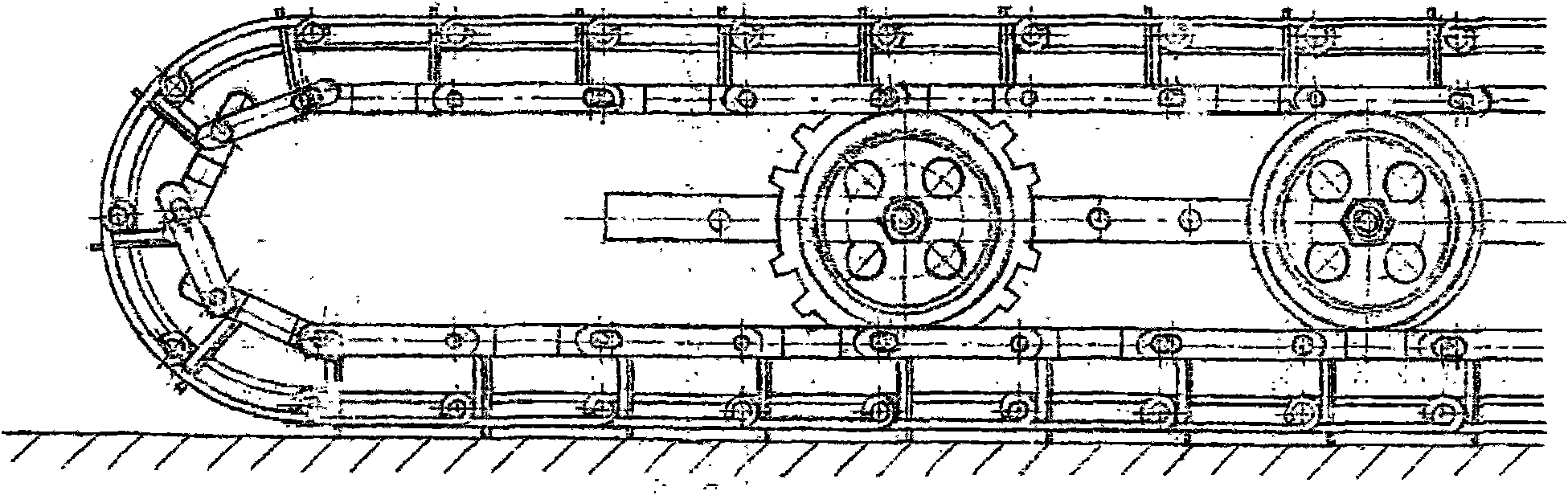

[0022] refer to figure 1 one Figure 11 , use the connecting pin 11 to connect the two sides of one side of the umbilical cable bearing bridge plate 5 with two kinds of torsion springs 2 and 3 at the same time, and connect the other side of the bearing bridge plate 5 with the freely adjustable chain rail 4, and connect them in turn to form a certain length The elastic drag chain body, and then press the main view of the implementation figure 1 The support rollers 7 and 8 are determined according to the width dimension of the whole towline after assembly, the full travel length of the towline and the load condition to determine the logarithm of the support rollers 7 and 8 to form an integral support mechanism and place it on the freely adjustable chain rail 4 of the towline. To meet the effect of flexible and free rolling support, then bend the other end of the elastic drag chain body so that the freely adjustable chain rail is pressed on the support rollers 7 and 8 and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com