Inlay combined type large self-lubricating support bearing

A support bearing and combined technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of inability to manufacture large self-lubricating support bearings, high manufacturing costs, and complex processes, shortening the maintenance cycle and reducing production. cost, quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

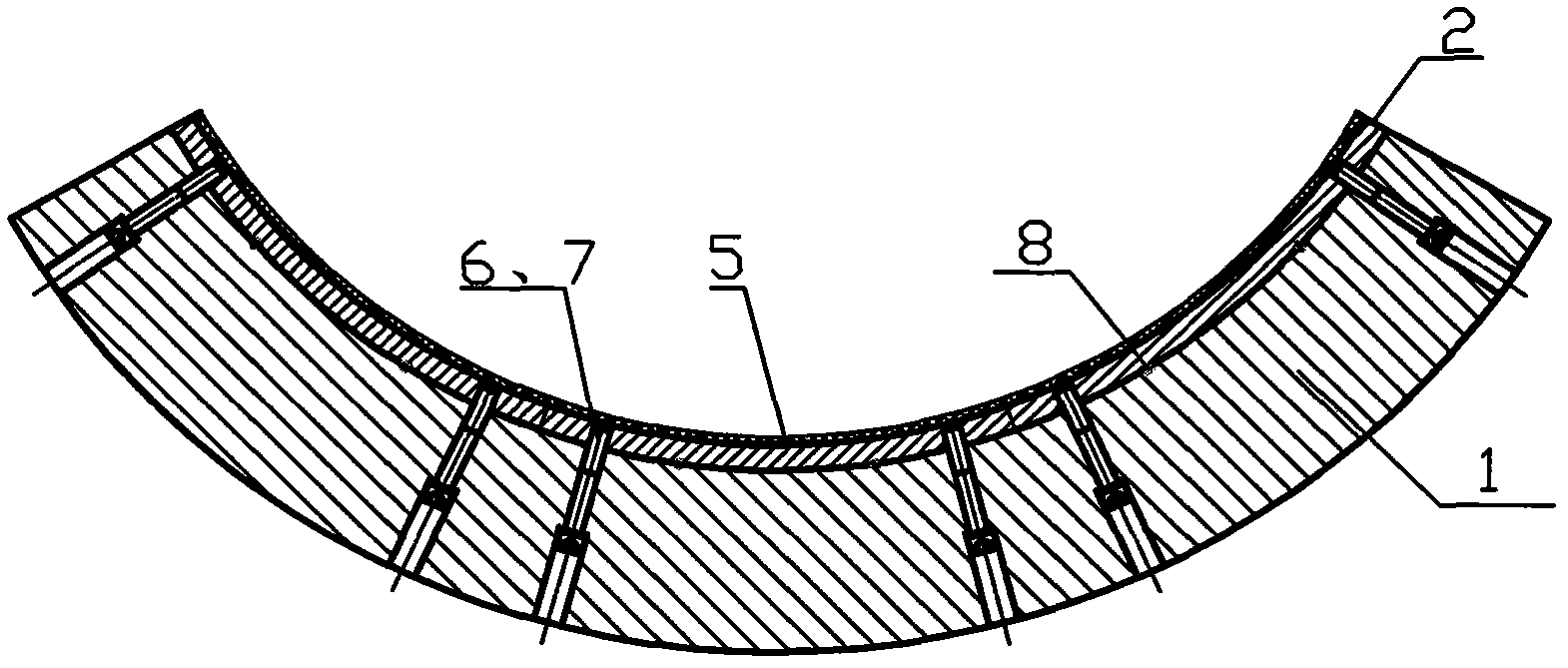

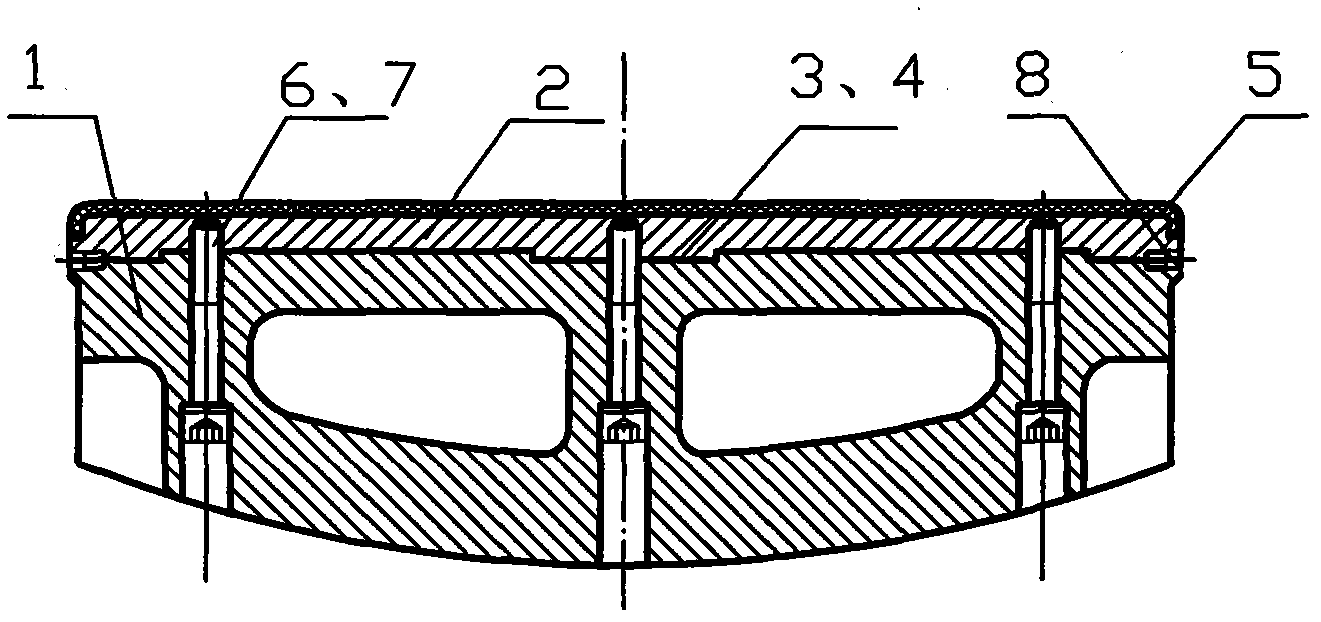

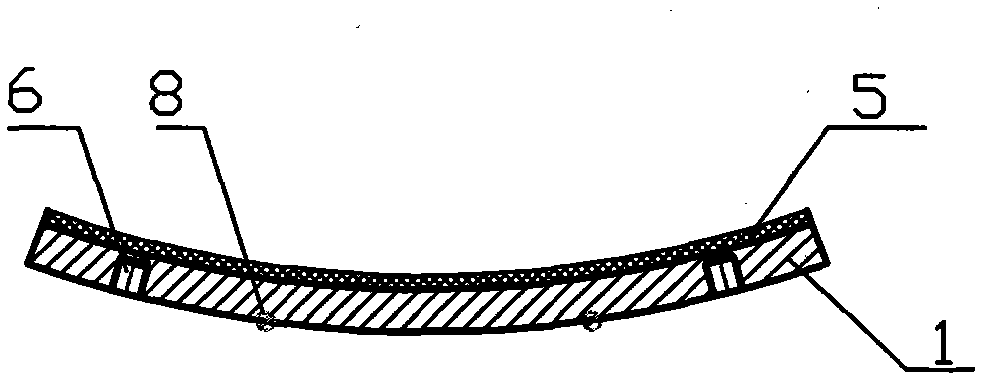

[0015] like figure 1 , 2 , shown in 3: there is the same arc-shaped tile seat 1 as the prior art, and the difference with the prior art is that the inner surface of the arc-shaped tile seat 1 is provided with multiple pieces spliced along the circumferential direction and the width is the same as that of the arc-shaped tile seat 1. Equal steel-backed metal-plastic composite bearings2. On the inner surface of the arc-shaped tile seat 1, there is a groove along the circumference, that is, the axial limit groove 3, and on the corresponding surface of the steel-backed metal-plastic composite bearing bush 2, a boss 4 matching the axial limit groove 3 is provided. The tile surface 5 of the steel-backed metal-plastic composite bearing bush 4 is an integral structure, and the joint surface with the steel matrix 6 has a radial arc surface, a thrust end surface and a transition arc surface, and each steel-back metal-plastic composite The steel matrix 6 of the bearing bush is process...

Embodiment 2

[0018] The basic structure is the same as that of Embodiment 1, and the difference from Embodiment 1 is that positioning pins 6 are provided at the axial ends of the tile seat 1 and the steel-backed metal-plastic composite bearing bush 2 to facilitate assembly and ensure quality.

Embodiment 3

[0020] The basic structure is the same as in Embodiment 1 or Embodiment 2. The depth of the screw hole 7 is preferably 70-80% of the thickness of the steel matrix 6, which will not affect the normal operation of the lubricated working surface and ensure a firm combination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com