PLC (Programmable Logic Controller) controlled variable-frequency piling machine

A frequency converter and controller technology, which is applied to the automatic control system of drilling, rotary drilling rig, drilling equipment and method, etc. The effect of high degree of automation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

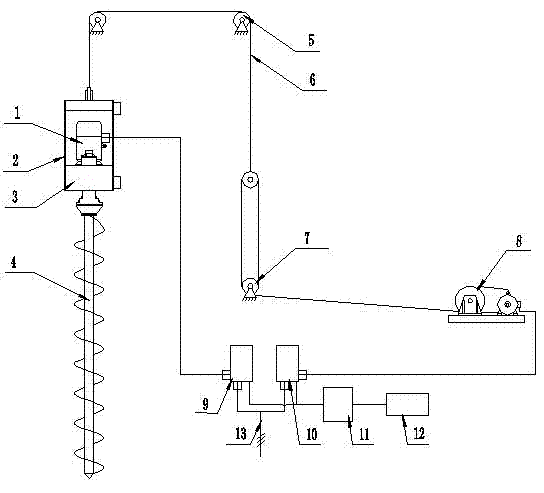

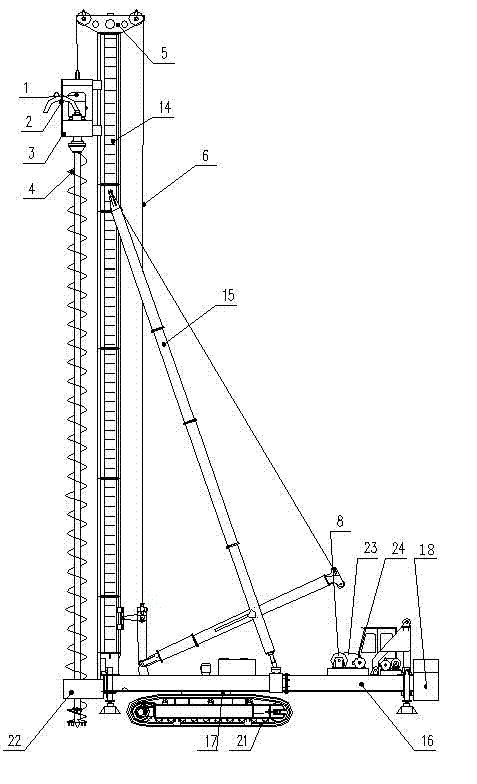

[0012] Below in conjunction with accompanying drawing, the present invention is further described:

[0013] As shown in the accompanying drawings, a PLC-controlled frequency conversion pile driver includes a pile frame and a long auger rod 4, a control device, an operating console 12 and a power supply 13, and the pile frame includes a column 14, a diagonal brace 15, a platform 16, a chassis 17, Counterweight 18, pulley block 5 and traveling device 21, the control device includes a drilling tool speed control device and a drilling tool lifting control device, the drilling tool speed control device includes a speed reducer 3 and a motor 1, and the drilling tool lifting control device includes a speed reducer 23 and a motor 24. An operating switch and an ammeter are arranged on the console 12. The walking device can be a crawler type or a walking device. The platform 16 is fixedly connected with the running device 21 through the chassis 17. One end of the platform 16 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com