Diffusion electrode alkali producing device

A diffusion electrode and cathode technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of low-carbon environmental protection, high power consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

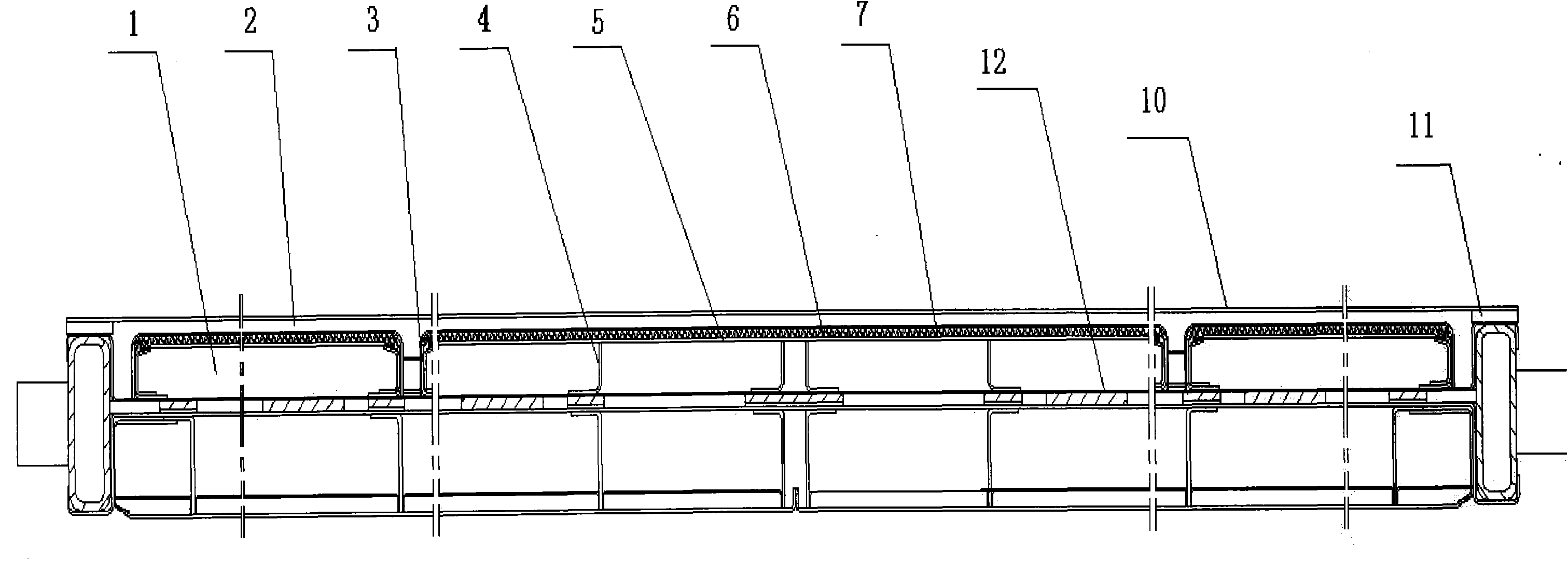

[0037] Combine below Figure 1 to Figure 5 , the present invention is further described:

[0038] A diffusion electrode alkali production device, mainly including the anode of the ion membrane electrolyzer and the cathode of the ion membrane electrolyzer, one or more gas chambers 1 and one or more liquid chambers 2 are arranged on the cathode side of the ion membrane electrolyzer , sending oxygen to the gas chamber 1, the purity of the oxygen sent to the gas chamber 1 is at least 94%. An oxygen cathode diffusion electrode 7 is arranged between the gas chamber 1 and the liquid chamber 2, and oxygen passes through the oxygen cathode diffusion electrode 7 to interact with H 2 O together transforms into OH - Enter the catholyte chamber 2, so that NaOH is generated in the catholyte chamber 2, while there is no H in the cathode of the ion-exchange membrane electrolyzer 2 Precipitate.

[0039] The overall reaction of this electrode process changes to:

[0040] 2NaCl+H 2 O+1 / 2O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com