Hyperbranched polymer flocculant for treating waste drilling fluid and preparation method thereof

A technology of hyperbranched polymer and waste drilling fluid, applied in the field of water treatment, can solve problems such as instability and pollution treatment effect, and achieve the effects of no secondary pollution, high flocculation efficiency, and simple synthesis method and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

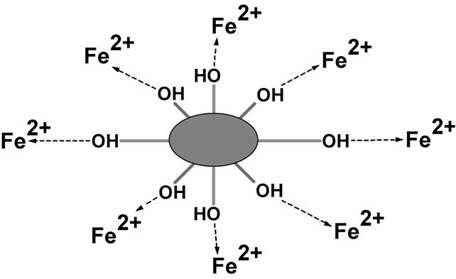

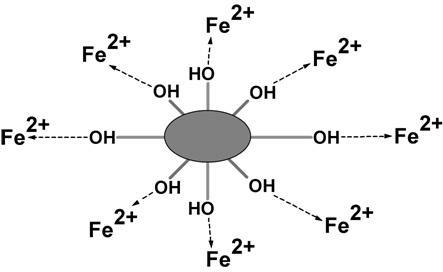

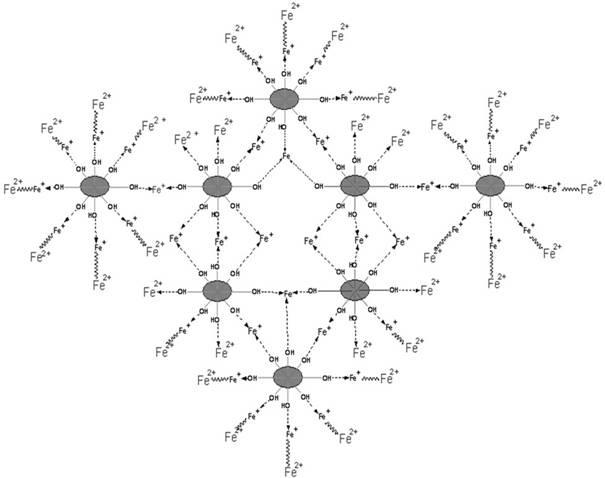

Method used

Image

Examples

Embodiment 1

[0031] 1. Synthesis of intermediates:

[0032] (1) AB 2 Synthesis of type monomer: in a three-necked flask, mix diethanolamine and methyl acrylate at a molar ratio of 1:1, add 300 mL / mol of N,N-dimethylacetamide based on the amount of diethanolamine, and heat up To 60 ℃, heat preservation reaction for 8h, and then vacuumize to remove N,N-dimethylacetamide and excess methyl acrylate to obtain colorless transparent oil AB 2 type monomer;

[0033] (2) Synthesis of hydroxyl-terminated hyperbranched polymers: controlling AB 2 The molar ratio of type monomer and trimethylol propane is 4:1 one-time feeding and reacting, then add trimethylol propane and AB 2 The phosphotungstic acid with a total mass ratio of 8% monomers was raised to 90°C, and after 6 hours of reaction, it was transferred to a rotary evaporator to continue the reaction until the system no longer bubbled out, and the hydroxyl-terminated hyperbranched polymer was prepared. Then it is made into a 50% aqueous solutio...

Embodiment 2

[0036] 1. Synthesis of intermediates:

[0037] (1) AB 2 Synthesis of type monomer: Mix diethanolamine and methyl acrylate in a three-necked flask at a molar ratio of 1:2, add 200mL / mol of methanol based on the amount of diethanolamine, raise the temperature to 35°C, and keep the reaction for 4h. Then vacuumize to remove methanol and excess methyl acrylate to obtain colorless transparent oil AB 2 type monomer;

[0038] (2) Synthesis of hydroxyl-terminated hyperbranched polymers: one-step control of AB with nuclei 2 The molar ratio of type monomer and trimethylol propane is 3:1 one-time feeding and reacting, then add trimethylol propane and AB 2 p-toluenesulfonic acid with a total mass ratio of 2% of monomers, heated up to 120 ° C, and transferred to a rotary evaporator after reacting for 5 hours to continue the reaction until the system no longer bubbles out, and the hydroxyl-terminated hyperbranched polymer was obtained , and then make it into a 30% aqueous solution interm...

Embodiment 3

[0041] 1. Synthesis of intermediates:

[0042] (1) AB 2 Synthesis of type monomer: in a three-necked flask, mix diethanolamine and methyl acrylate at a molar ratio of 1:3, add 50 mL / mol of dimethylformamide based on the amount of diethanolamine, and heat up to 70°C. Insulated for 8 hours, then vacuumed to remove dimethylformamide and excess methyl acrylate to obtain a colorless transparent oil AB 2 type monomer;

[0043] (2) Synthesis of hydroxyl-terminated hyperbranched polymers: one-step control of AB with nuclei 2 The molar ratio of type monomer and pentaerythritol is 4:1 one-time feeding and reacting, then add pentaerythritol and AB 2 Benzenesulfonic acid with a total mass ratio of 6% of the type monomer was heated up to 180°C, and after 8 hours of reaction, it was transferred to a rotary evaporator to continue the reaction until the system no longer bubbled out, and a hydroxyl-terminated hyperbranched polymer was obtained. Then it is made into 20% aqueous solution int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com