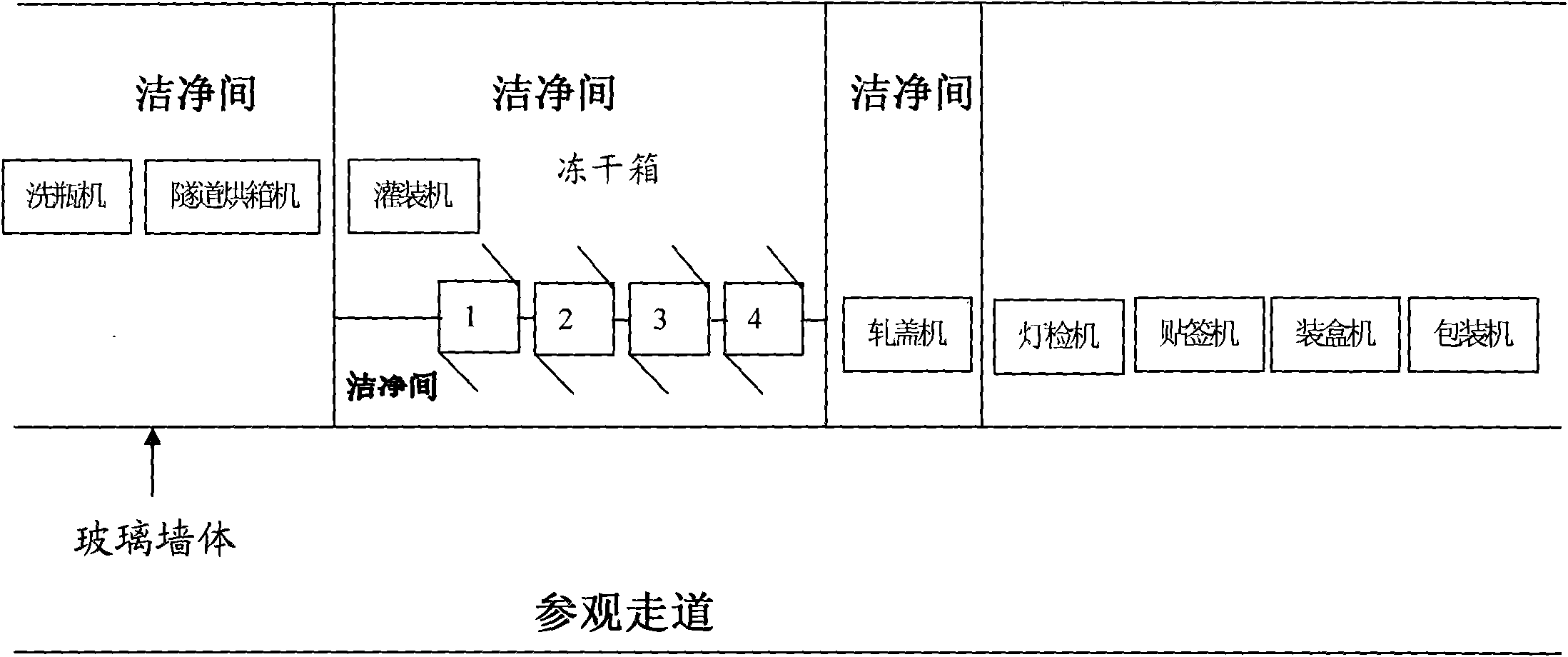

Continuous production process for freeze-dried preparation

A production process and technology of freeze-dried preparations, which are applied in the field of continuous production of freeze-dried products, can solve the problems of increasing aseptic rooms, which cannot be realized, and achieve the effect of solving the risk of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] To freeze-dry a certain freeze-dried product, the production capacity of bottle washing machine, tunnel sterilization oven, and liquid filling semi-corking machine is 400 bottles / min (2ml vials), and there are 4 sets of freeze-drying machines (each 30m 2 It can hold 2ml vials (140,000 vials), the dispensing time of this product is 1.5 hours, and the freeze-drying cycle is 20 hours. The whole process time is as follows:

[0013] On the first day, the medicines are dispensed from 8:00-9:30, the bottles are washed at 9:00, and the filling starts at 10:00. The first lyophilizer was filled and cleared at 16:00; the second lyophilizer was filled and cleared at 18:00; the third lyophilizer was filled and cleared at 2:00 the next day. Filling was completed at 8:00 and the site was cleared; the fourth unit was filled at 10:00, and the site was filled and cleared at 16:00. At the same time, the first box was released at 12:00 the next day, and the box was cleared at 16:00; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com