Method for producing chicken flavor collagen concentrated soup by utilizing chicken skeletons and chicken claws

A technology of collagen and chicken skeleton, which is applied in the field of chicken-flavored collagen concentrated soup, can solve the problems of low collagen content, unsatisfactory product umami, and insufficient nutritional value, so as to achieve broad market prospects, avoid losses, Maintain skin elasticity and moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

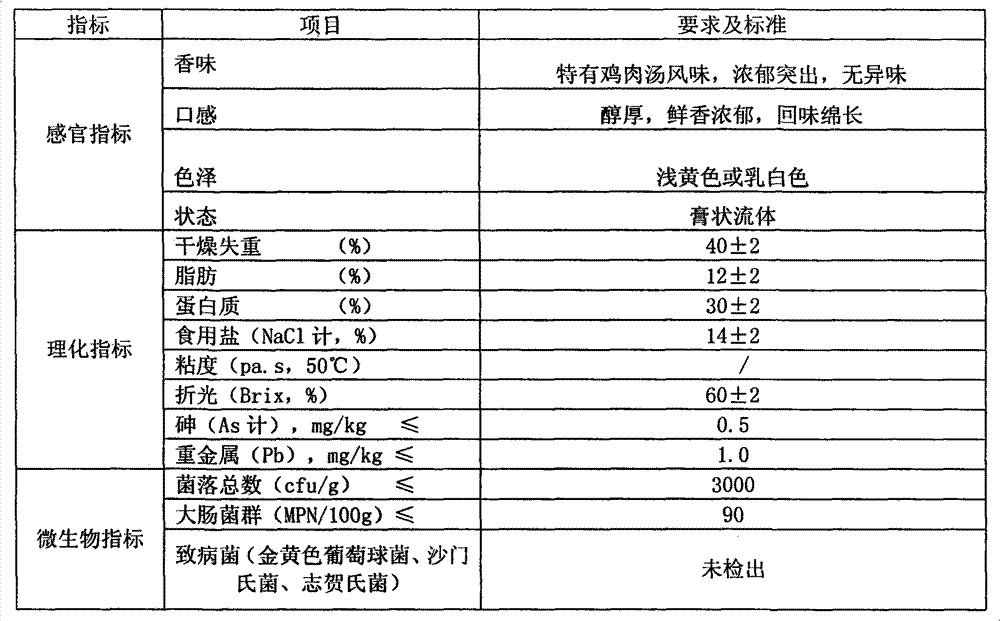

Image

Examples

Embodiment 1

[0019] Utilize chicken skeleton and chicken feet of the present invention to produce the method for chicken flavor collagen concentrated soup, this method is to carry out according to the following steps:

[0020] (1) Cooking extraction: put 800 parts by weight of chicken skeleton and 100 parts by weight of chicken feet into a high-pressure extraction tank, open the heating valve, start the stirring device to soak the chicken bones and chicken feet in hot water at a temperature of 60°C After 20 minutes, let off hot water, then add the cold water of 2000 parts by weight, drop into the chives of 45 parts by weight, the ginger of 10 parts by weight, the Chinese prickly ash of 15 parts by weight, the capsicum of 3 parts by weight, the pepper of 5 parts by weight, When the temperature is raised to 80°C, the circulating pump is turned on for circulation, the temperature is raised to 98°C and the exhaust valve is closed, and the temperature is raised to 105°C for cooking. The cooking...

Embodiment 2

[0026] Utilize chicken skeleton and chicken feet of the present invention to produce the method for chicken flavor collagen concentrated soup, this method is to carry out according to the following steps:

[0027] (1) Cooking extraction: put 900 parts by weight of chicken skeleton and 100 parts by weight of chicken feet into a high-pressure extraction tank, open the heating valve, start the stirring device to soak the chicken bones and chicken feet in hot water at a temperature of 65°C After 15 minutes, let off hot water, then add the cold water of 2000 parts by weight, drop into the chives of 50 parts by weight, the ginger of 5 parts by weight, the Chinese prickly ash of 20 parts by weight, the capsicum of 5 parts by weight, the pepper of 3 parts by weight, When the temperature rises to 80°C, the circulation pump is turned on for circulation, the temperature is raised to 98°C and the exhaust valve is closed, and the temperature is raised to 105°C. The cooking temperature is 1...

Embodiment 3

[0033] Utilize chicken skeleton and chicken feet of the present invention to produce the method for chicken flavor collagen concentrated soup, this method is to carry out according to the following steps:

[0034] (1) Cooking extraction: put 1000 parts by weight of chicken skeleton and 100 parts by weight of chicken feet into a high-pressure extraction tank, open the heating valve, start the stirring device to soak the chicken bones and chicken feet in hot water at a temperature of 70°C After 10 minutes, let off hot water, then add the cold water of 2000 parts by weight, drop into the chives of 55 parts by weight, the ginger of 15 parts by weight, the Chinese prickly ash of 25 parts by weight, the capsicum of 8 parts by weight, the pepper of 2 parts by weight, When the temperature rises to 80°C, the circulation pump is turned on for circulation, the temperature is raised to 98°C and the exhaust valve is closed, and the temperature is raised to 105°C. The cooking temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com