Mechanical step speed changer for harvester

A technology for harvesters and transmissions, applied in harvesters, mechanical drive clutches, mechanical equipment, etc., can solve the problems of heavy transmission weight, time-consuming and complicated operation, and high cost of use, reducing fuel consumption, easy operation, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

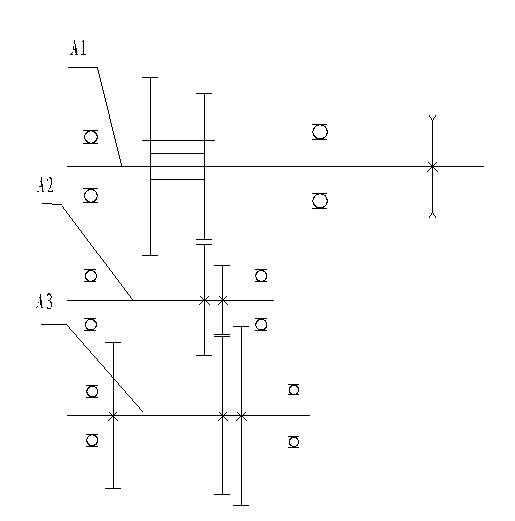

[0028] Such as figure 1 As shown, the transmission system of the present invention includes a power input shaft system A1, an intermediate shaft system A2, and a power output shaft system A3 arranged in parallel in sequence.

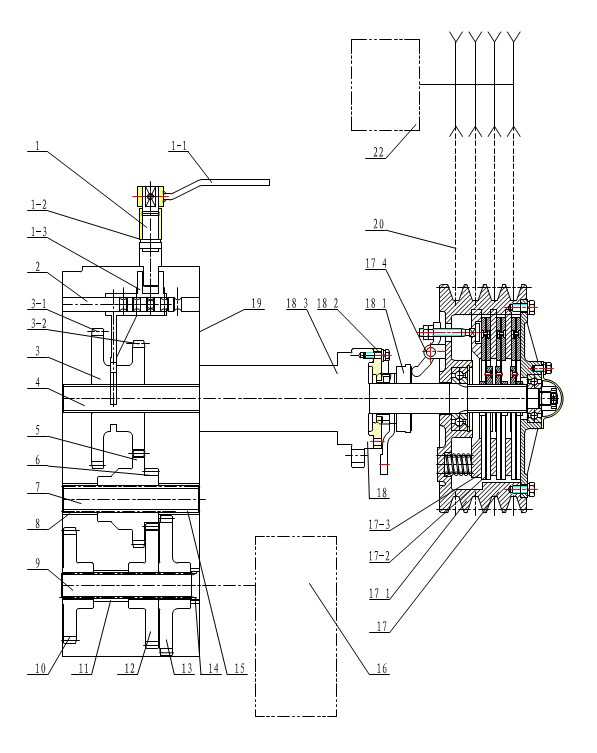

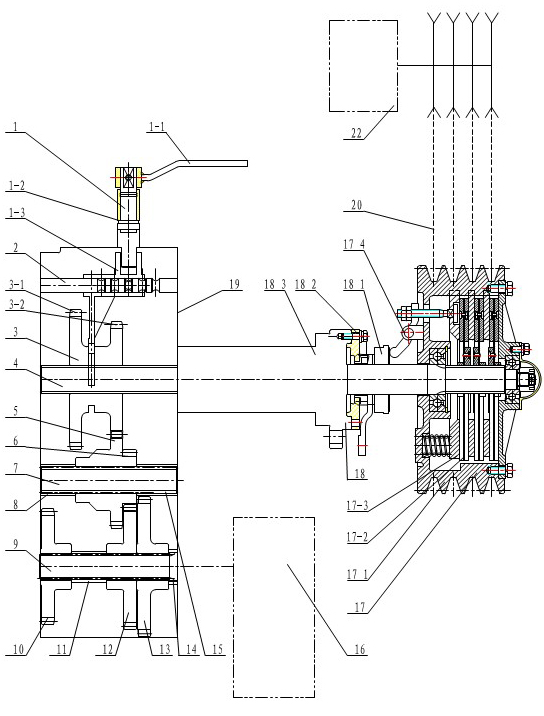

[0029] Such as figure 1 and figure 2 As shown, the power input shaft system includes a double sliding gear 3 installed on the power input shaft 4, and a clutch assembly 17 and a separation pawl system assembly 18 installed on the input end of the power input shaft 4; :Double sliding gear 3 includes parallel sliding gear Ⅰ3-1, double sliding gear Ⅱ 3-2; clutch assembly 17 includes clutch 17-1, friction plate 17-2, light plate 17-3 and clutch Lever 17-4; the separation claw system assembly 18 includes a separation claw 18-1, a separation claw seat 18-2, and a separation coupling sleeve 18-3.

[0030] Such as figure 1 and figure 2 As shown, the intermediate shaft system includes a sleeve I8, an intermediate large gear 5, an intermediate pinion 6, and a shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com