Novel method for preparing ready-to-bake frozen doughs

A technology for freezing dough and dough, which is applied in the direction of dough processing, dough ready for oven, dough preparation, etc., and can solve economically unfeasible problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Example 1: Partially Proofed Frozen Dough

[0091] Prepare the dough using flour, salt, leavening agent, improver and water. The proportions of the different ingredients used in this process are summarized in Table 1. Improvers include emulsifiers, gluten, ascorbic acid and enzymes. The first composition (Test 1) contained fresh yeast as starter, while the second composition (Test 2) contained IADY as starter.

[0092] Table 1

[0093]

test 1

test 2

Element

grams

grams

Cereal Flour (Paniflower, Brabomills, Belgium)

5000

5000

Salt

100

100

[0094] Fresh yeast (Levante, Puratos, Belgium)

300

0

Instant active dry yeast (Okedo, Puratos, Belgium)

0

100

Improver (S Kimo long, Puratos, Belgium)

200

200

water

2950

2750

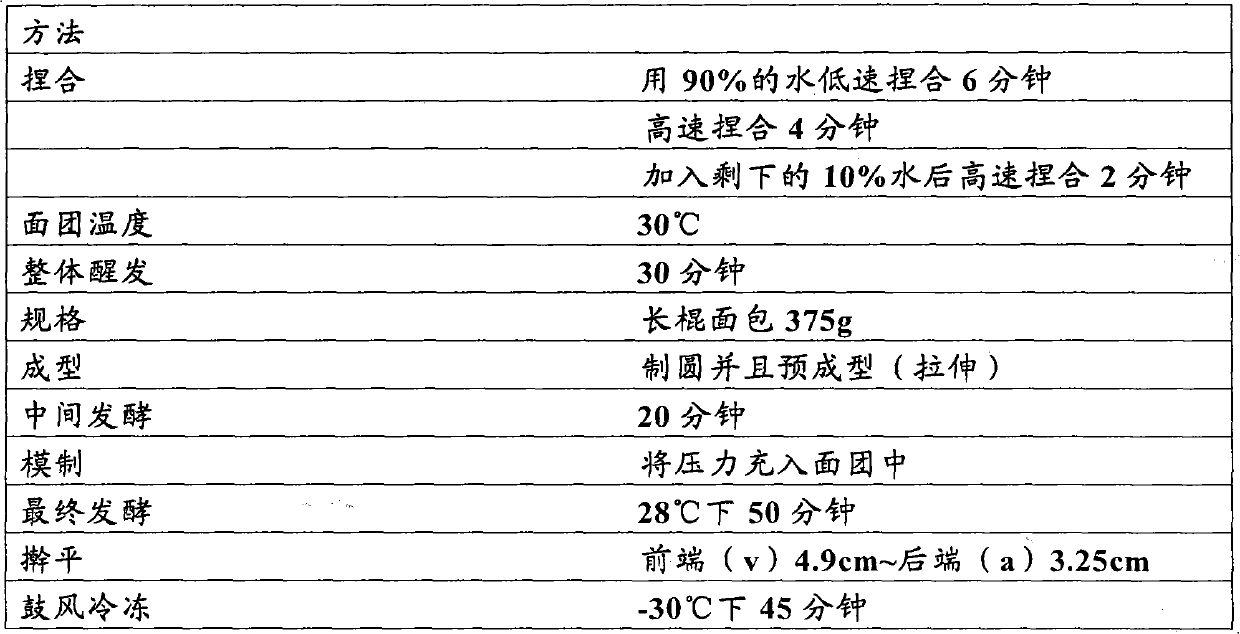

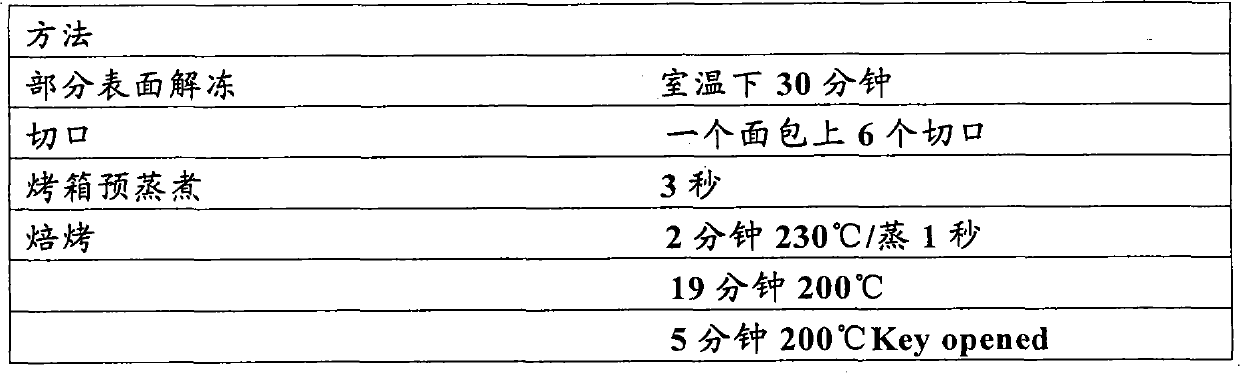

[0095] Processing methods are described in Table 2.

[0096] Table 2

[0097]

[0098]Different dough...

Embodiment 2

[0110] Example 2: Fully Fermented Frozen Dough

[0111] Prepare the dough using flour, salt, leavening agent and water. The ratios of the different ingredients used in this process are summarized in Table 6.

[0112] Table 6

[0113] Element

grams

Cereal Flour (DUO, Céres, Belgium)

5000

Salt

100

O-tentic (Puratos, Belgium)

200

water

3400

[0114] O-Tentic is a "sourdough-based active baking ingredient" that contains instant active dry yeast, sourdough, enzymes and ascorbic acid. The final concentration of IADY in the dough was 8 g / 1 kg flour.

[0115] Treatment methods are described in Table 7.

[0116] Table 7

[0117]

[0118] Different doughs were prepared following the methods described in Table 2 and using different ingredients. The comparative processing steps are summarized in Table 8.

[0119] Table 8

[0120] Test n°

Processing steps

1

direct freezing

2

...

Embodiment 3

[0133] Example 3: Fully Fermented Frozen Dough

[0134] Baguette dough is prepared from flour, salt, leavening agent or fresh or instant active dry yeast (IADY) and / or dry sourdough and improver and water. The ratios of the different ingredients used in the tests are summarized in Table 11.

[0135] Table 11

[0136]

[0137] S500 Conditioner is a bread improver containing dextrose, emulsifiers, gums, ascorbic acid and enzymes.

[0138] Quick step crispy is a bread improver containing dextrose, emulsifiers, gums, malt flour, gluten, ascorbic acid and enzymes.

[0139] The ingredients and dough were processed as described in Table 12.

[0140] Table 12

[0141]

[0142] Different final doughs were obtained using the recipe in Table 11 and the final additional processing steps described in Table 13.

[0143] Table 13

[0144]

[0145] Rolling out is done by passing the dough through a croissant dough laminator. The height of the dough was reduced by about 50%.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com