Inclined cavity surface two-dimensional photonic crystal distribution feedback quantum cascade laser and preparation method

A two-dimensional photonic crystal, distributed feedback technology, used in semiconductor lasers, lasers, phonon exciters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

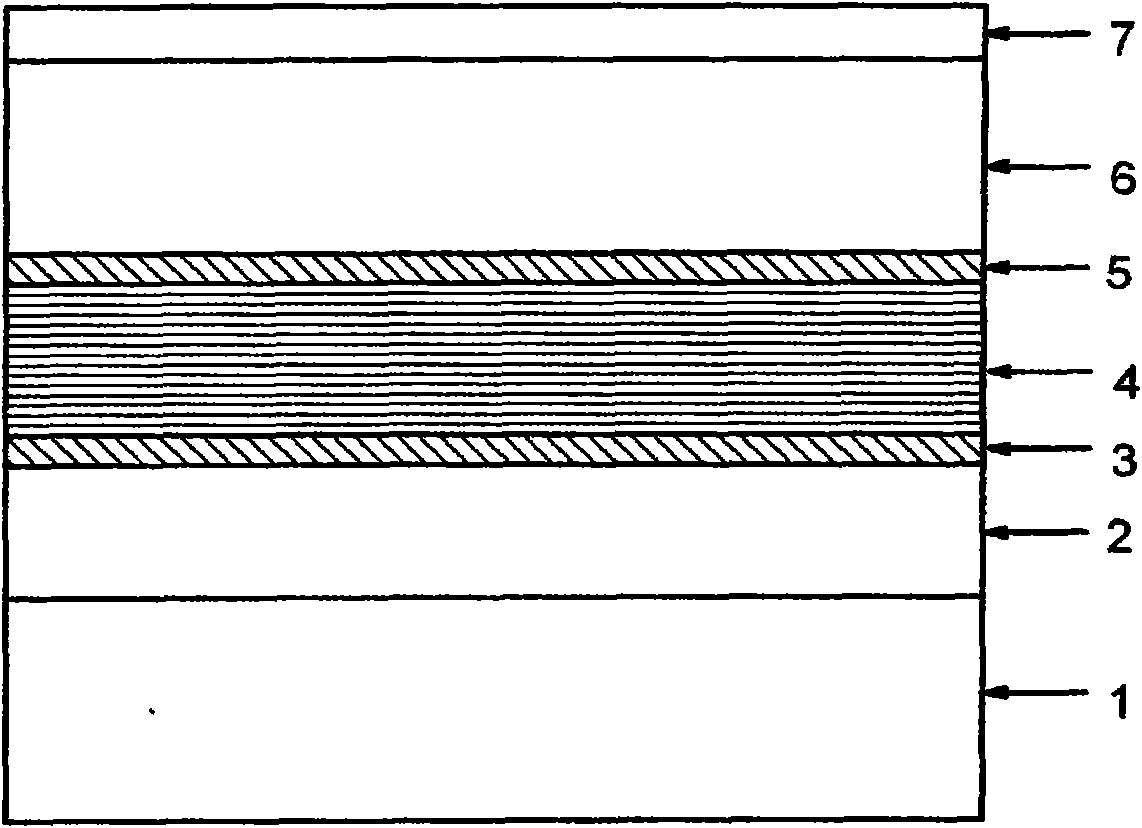

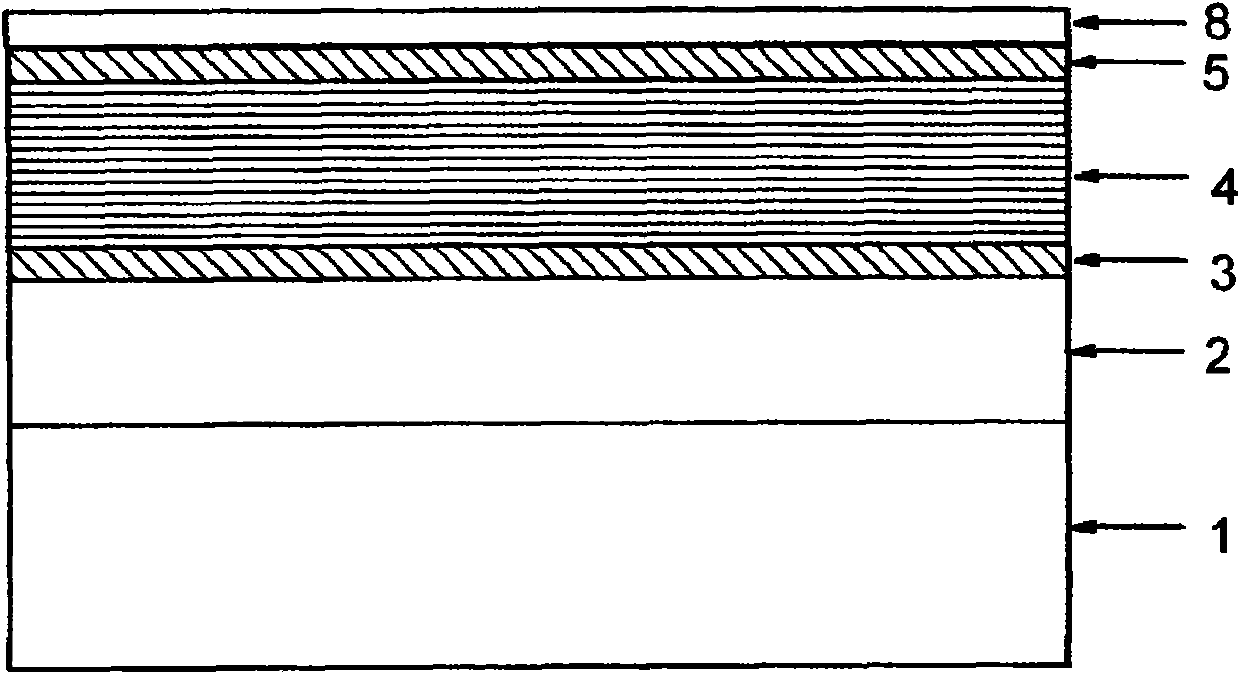

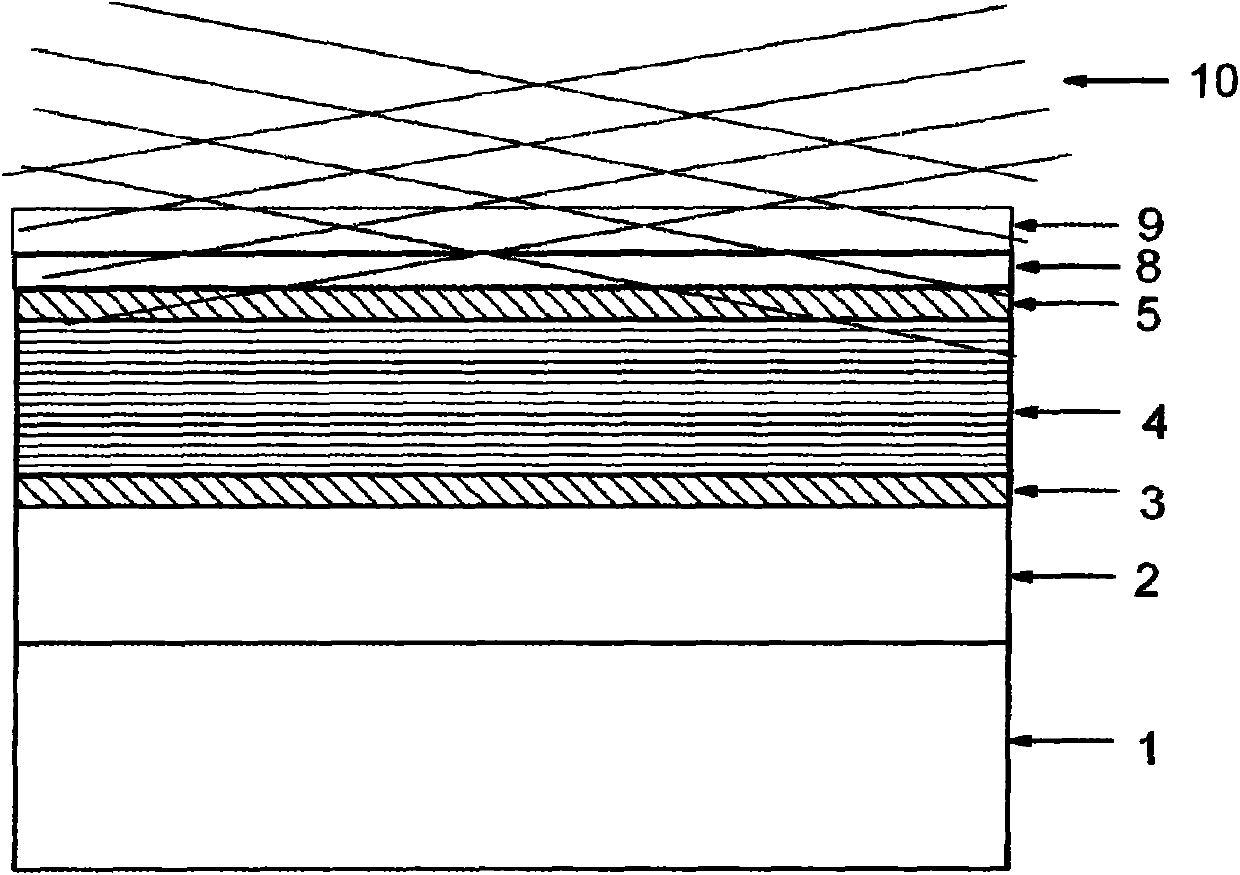

[0048] see Figure 1 to Figure 12 , the present invention provides a two-dimensional photonic crystal distributed feedback quantum cascade laser with inclined cavity surface, comprising:

[0049] An InP substrate 1; wherein the doping concentration of the InP substrate 1 is 3×10 17 cm -3 ;

[0050] An InP waveguide confinement layer 2, the InP waveguide confinement layer 2 is fabricated on the InP substrate 1, and its doping concentration is 2-6×10 16 cm -3 , the thickness is 0.8-1.3μm;

[0051] An InGaAs lower waveguide layer 3, the InGaAs lower waveguide layer 3 is fabricated on the InP waveguide confinement layer 2, and its doping concentration is 3-6×10 16 cm -3 , the thickness is 200-400nm;

[0052] A strain compensation active layer 4 is a multi-layer InGaAs and InAlAs periodic structure, the strain compensation active layer 4 is fabricated on the InGaAs lower waveguide layer 3, its total thickness is 1.57 μm, and the designed lasing wavelength is 4.6 μm;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com